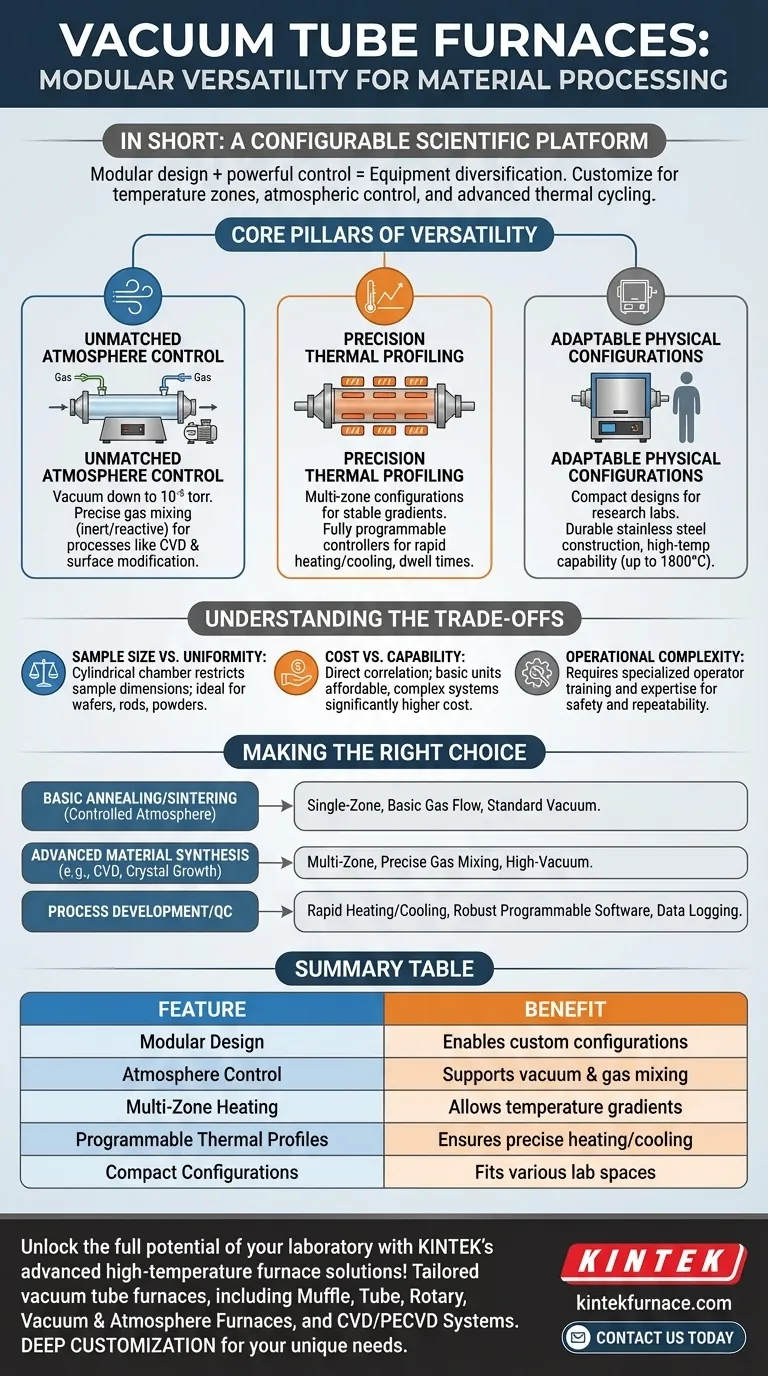

In short, the equipment diversification of vacuum tube furnaces stems from their modular design and a powerful combination of highly controllable features. They are not a single type of device but a versatile platform that can be configured with different temperature zones, precise atmospheric controls, and advanced thermal cycling capabilities to meet the specific demands of new material processing.

A vacuum tube furnace's standout versatility comes from its ability to precisely and independently control the three fundamental pillars of material processing: temperature, atmosphere, and time. This makes it less like a simple oven and more like a configurable scientific instrument.

The Core Pillars of Versatility

The true strength of vacuum tube furnaces lies in a set of core features that can be combined in various ways, creating a wide diversity of equipment tailored to specific scientific and industrial processes. Understanding these pillars reveals why they are so adaptable.

Unmatched Atmosphere Control

A defining feature is the ability to create highly specific, controlled environments. This is not just about heating; it's about controlling the chemical environment in which heating occurs.

This control is achieved through sealed tube designs, robust end caps, and sophisticated support systems. These allow for vacuum conditions down to 10⁻⁵ torr, creating an ultra-pure environment free of reactive gases like oxygen.

Furthermore, integrated gas mixing systems enable the introduction of precise mixtures of inert (like Argon) or reactive gases. This capability is critical for processes like chemical vapor deposition (CVD) or creating specific nitriding or carburizing effects on a material's surface.

Precision Thermal Profiling

Vacuum tube furnaces offer exceptional control over the entire heating and cooling cycle, known as the thermal profile. This goes far beyond simply reaching a target temperature.

Multi-zone configurations are a key aspect of this. A furnace can have several independent heating zones along the length of the tube, allowing a user to create a stable temperature gradient. This is essential for processes like crystal growth.

Advanced, fully programmable controllers allow for precise management of heating rates, dwell times at specific temperatures, and cooling rates. Features like rapid heating save valuable production time, while fast cooling capabilities can reduce thermal stress and improve the final quality and microstructure of the material.

Adaptable Physical Configurations

The diversification is also physical. These furnaces are designed to fit a range of lab spaces and processing needs, from small-scale research to pilot production.

Many models feature compact, bench-top designs, making them ideal for research labs where space is a premium. The construction often uses durable stainless steel and corrosion-resistant materials to ensure a long service life, even when using reactive gases.

This combination of a small footprint with high-temperature capability (up to 1800°C in some models) and advanced process control makes them a uniquely powerful tool in a compact package.

Understanding the Trade-offs

While highly versatile, vacuum tube furnaces are not a universal solution. Understanding their limitations is key to making an informed decision.

Sample Size vs. Uniformity

The primary limitation is inherent in the name: the tube. The cylindrical chamber restricts the physical dimensions of the sample. While excellent for wafers, rods, or powders, they are unsuitable for large, bulky, or irregularly shaped components that would be better served by a box furnace.

Cost vs. Capability

There is a direct correlation between price and features. A basic, single-zone furnace for simple annealing is relatively affordable. However, a multi-zone system with high-vacuum pumps, mass flow controllers for gas mixing, and advanced data-logging software represents a significant increase in complexity and cost.

Operational Complexity

The precision that makes these furnaces so powerful also demands a higher level of operator knowledge. Properly programming complex thermal profiles, managing gas flows, and operating high-vacuum systems require specific training and expertise to ensure both safety and process repeatability.

Making the Right Choice for Your Goal

Selecting the right configuration depends entirely on your end goal.

- If your primary focus is basic annealing or sintering in a controlled atmosphere: A single-zone furnace with basic gas flow and a standard vacuum pump is likely sufficient and cost-effective.

- If your primary focus is advanced material synthesis (e.g., CVD, crystal growth): You will need a multi-zone furnace with precise gas mixing systems and high-vacuum capabilities to control gradients and purity.

- If your primary focus is process development or quality control: Prioritize models with rapid heating/cooling cycles and robust software for programmable control and detailed data logging.

By understanding these core capabilities and trade-offs, you can select a vacuum tube furnace that serves as a precise and powerful tool for your specific material processing objectives.

Summary Table:

| Feature | Benefit |

|---|---|

| Modular Design | Enables custom configurations for specific processes |

| Atmosphere Control | Supports vacuum and gas mixing for purity and reactions |

| Multi-Zone Heating | Allows temperature gradients for advanced synthesis |

| Programmable Thermal Profiles | Ensures precise heating and cooling cycles |

| Compact Configurations | Fits various lab spaces from research to production |

Unlock the full potential of your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with tailored vacuum tube furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure we meet your unique experimental needs precisely. Contact us today to discuss how our solutions can enhance your material processing efficiency and results!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is an atmosphere protection muffle furnace? Unlock Precise Heat Treatment in Controlled Environments

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios

- Can box type high-temperature resistance furnaces control the atmosphere? Unlock Precision in Material Processing