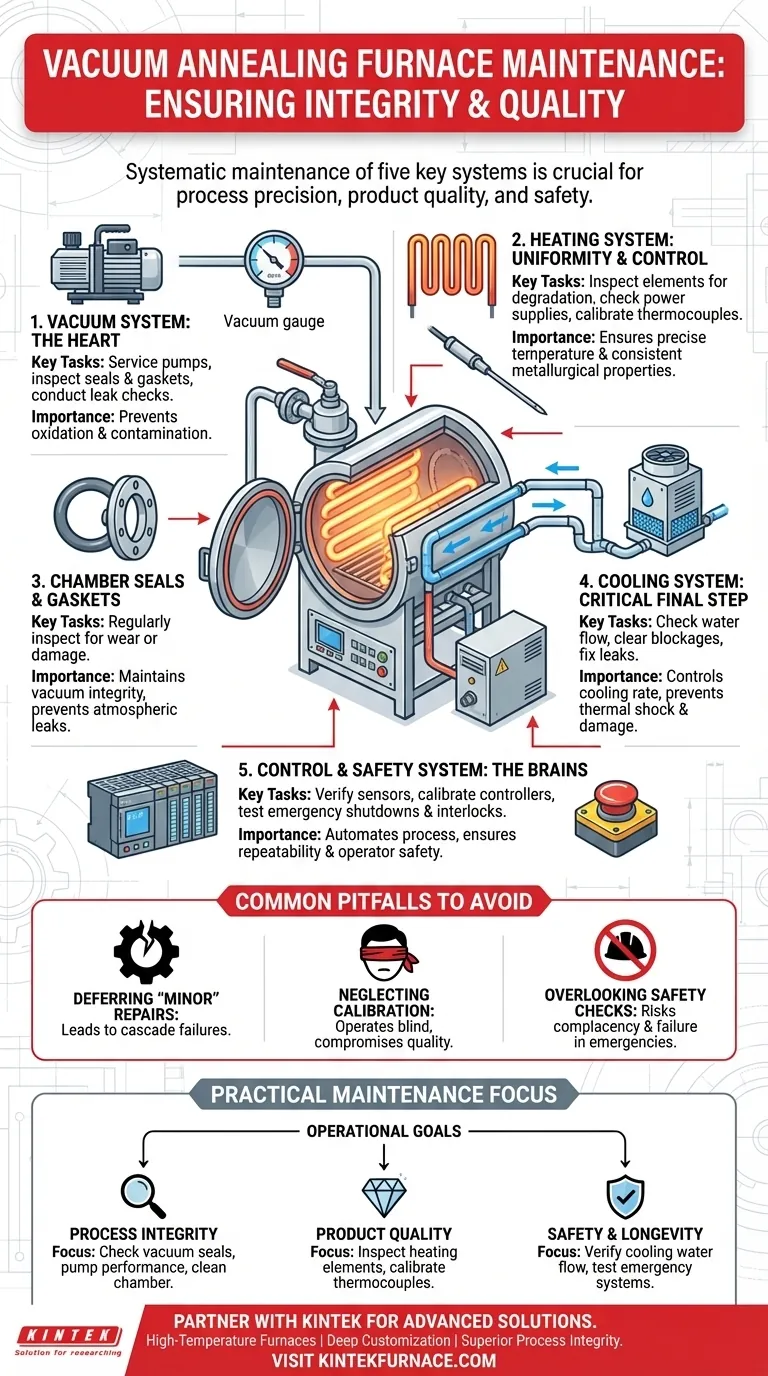

At its core, maintaining a vacuum annealing furnace is about systematically ensuring the integrity of five key systems. The required maintenance focuses on the vacuum pump, heating elements, chamber seals and gaskets, the cooling system, and the electronic control systems. Neglecting any of these areas compromises the furnace's ability to prevent oxidation and deliver consistent, high-quality results.

The goal of furnace maintenance is not merely to prevent breakdowns. It is to guarantee the precision of the entire annealing process—from creating a pure vacuum environment to achieving exact thermal profiles—ensuring both product quality and operator safety.

The Core Systems Requiring Attention

A vacuum furnace is an integrated system where the failure of one component can cascade, affecting the entire process. Effective maintenance requires a methodical approach to each of its critical subsystems.

The Vacuum System: The Heart of the Process

The primary function of the furnace is to remove the atmosphere, and this task falls to the vacuum system. Its health is paramount for preventing oxidation and contamination of the workpiece.

Key maintenance tasks include regular servicing of the vacuum pumps, inspecting all seals and gaskets for wear or damage, and periodically conducting leak checks on the chamber itself.

A slow leak or underperforming pump directly compromises the vacuum level, which can ruin an entire batch of high-value parts.

The Heating System: Ensuring Uniformity and Control

The heating system is responsible for raising the workpiece to a precise temperature and holding it there. Uniformity and accuracy are essential for achieving the desired metallurgical properties, such as stress relief or recrystallization.

Maintenance involves visually inspecting heating elements for signs of degradation or distortion and checking their power supplies.

Critically, thermocouples must be checked for accuracy and calibrated or replaced regularly. An inaccurate temperature reading leads to incorrect heat treatment and inconsistent product quality.

The Cooling System: The Critical Final Step

Controlled cooling is just as important as heating. This system, often using circulating water or inert gas, removes heat at a specified rate to finalize the material's microstructure.

You must regularly check the water cooling systems for adequate flow and look for any blockages or leaks. Impeded cooling can lead to thermal shock, damage to the furnace, or failure to achieve the desired material properties.

The Control & Safety System: The Brains of the Operation

Modern furnaces rely on sophisticated control systems, often using a PLC (Programmable Logic Controller), to automate and monitor the process. These systems ensure repeatability and execute vital safety functions.

Maintenance includes verifying that all sensors are reporting correctly and that the temperature controllers are calibrated. It is also crucial to periodically test all emergency shutdown systems and safety interlocks.

Common Pitfalls to Avoid

Understanding common failure points is as important as following a maintenance checklist. The biggest mistake is viewing maintenance as an avoidable cost rather than a necessary investment in quality and safety.

Deferring "Minor" Repairs

A small, slow vacuum leak or a slightly reduced water flow can seem insignificant. However, these issues place constant stress on other components, like vacuum pumps and heating elements, causing them to work harder and fail prematurely.

Neglecting Calibration

Failing to calibrate thermocouples and pressure sensors is a critical error. Without accurate data, the furnace's control system is operating blind, making it impossible to guarantee that the process meets specifications.

Overlooking Safety Checks

Safety interlocks and emergency shutdown systems are rarely used, which can lead to complacency. These systems must be tested on a regular schedule to ensure they will function correctly in an emergency, protecting both personnel and the equipment.

A Practical Maintenance Focus

Your maintenance strategy should be guided by your primary operational goals: process integrity, product quality, and long-term safety.

- If your primary focus is process integrity: Regularly check vacuum seals, pump performance, and clean the chamber to prevent workpiece contamination from oxidation.

- If your primary focus is product quality: Routinely inspect heating elements for wear and calibrate all thermocouples to ensure accurate and uniform temperature control.

- If your primary focus is safety and longevity: Consistently verify cooling water flow rates and methodically test all emergency shutdown and safety interlock systems.

Consistent maintenance transforms your furnace from a potential point of failure into a reliable asset for producing superior quality components.

Summary Table:

| System | Key Maintenance Tasks |

|---|---|

| Vacuum System | Service pumps, inspect seals, conduct leak checks |

| Heating System | Inspect elements, calibrate thermocouples |

| Cooling System | Check water flow, prevent blockages |

| Control & Safety | Verify sensors, test emergency shutdowns |

Ensure your vacuum annealing furnace operates at peak efficiency with KINTEK's advanced solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs for superior process integrity and product quality. Contact us today to discuss how we can support your maintenance and performance goals!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- How does a vacuum heat treatment furnace prevent contamination? Ensure Purity in High-Temperature Processes

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions

- Why should nitrogen not be used as a cooling gas for titanium alloys in vacuum heat treatment? Avoid Catastrophic Failures

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing