In essence, vacuum brazing is a high-purity material joining process that uses a filler metal to form a bond between two or more components inside a vacuum furnace. The process works by heating an assembly so that the filler metal melts and flows into the tight gaps between the parts via capillary action. Because this occurs in a vacuum, a pristine, oxygen-free environment, the resulting bond is exceptionally strong, clean, and free from the oxides that can compromise traditional joining methods.

The core value of vacuum brazing is not just joining parts, but creating a flawlessly clean and strong metallurgical bond. By removing atmospheric contaminants, the process enables the joining of complex assemblies and dissimilar materials with a level of integrity that is often unattainable with other methods.

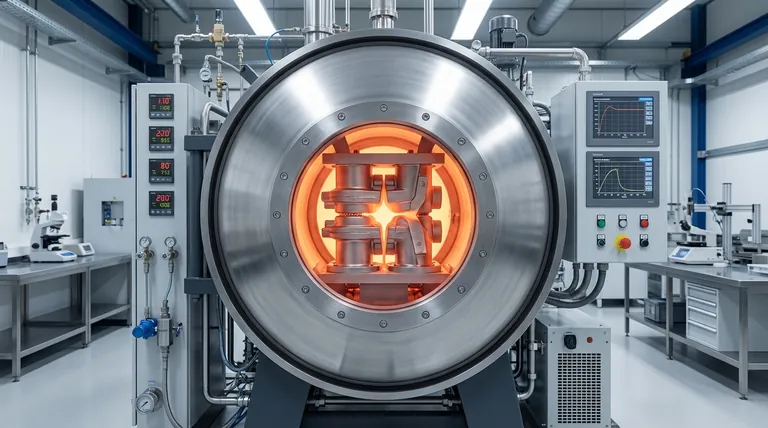

The Core Principle: A Controlled, Contamination-Free Environment

Vacuum brazing's success hinges on creating a perfect environment for a metallurgical bond to form. Unlike welding, which melts the base materials, brazing uses a third material—a filler—to act as the joining agent.

The Role of the Vacuum

The primary purpose of the vacuum is to remove oxygen and other atmospheric gases from the furnace chamber. Metal surfaces, especially when heated, rapidly form oxide layers. These layers act as a barrier, preventing the molten filler metal from properly wetting and bonding with the base materials, resulting in a weak or failed joint.

By performing the process in a vacuum, oxidation is virtually eliminated. This removes the need for corrosive chemical fluxes that are required in traditional brazing and which must be meticulously cleaned off afterward.

How the Filler Metal Works

A brazing filler metal is chosen with a melting point that is lower than the base materials being joined. This filler, often in the form of a paste, foil, or wire, is placed along the joint before the assembly is heated.

When the furnace reaches the designated brazing temperature, the filler melts and becomes liquid while the parent materials remain solid.

Capillary Action: The Driving Force

Once molten, the filler metal is drawn into the tight gap between the components through a physical phenomenon called capillary action. This force ensures the filler flows evenly throughout the entire joint, filling microscopic voids and creating a complete, gap-free connection.

Upon cooling, the filler solidifies, forming a strong, permanent intermetallic bond between itself and the base materials.

A Step-by-Step Look at the Vacuum Brazing Cycle

The vacuum brazing process is a precise, multi-stage thermal cycle that requires careful control to achieve optimal results. Each step is critical to the final quality of the joint.

Step 1: Preparation and Assembly

Parts must be thoroughly cleaned to remove any oils, dirt, or other contaminants. They are then precisely assembled with the filler material pre-placed at or near the joints. The gap between the parts is a critical design parameter.

Step 2: The Furnace Environment

The assembled component is loaded into a vacuum furnace. The furnace door is sealed, and powerful pumps remove the air, creating a high-vacuum environment. In some cases, the chamber may then be backfilled with an inert gas like high-purity argon to create a protective atmosphere at a specific pressure.

Step 3: The Thermal Cycle: Heating and Soaking

The furnace temperature is carefully ramped up to the target brazing temperature, typically between 800°C and 1150°C. This temperature is above the filler metal's melting point but safely below that of the base materials.

The assembly is held at this temperature—a phase known as "soaking"—for a short period, often around 10 minutes. This ensures the entire part reaches a uniform temperature and gives the filler metal sufficient time to melt and flow completely through the joints.

Step 4: Controlled Cooling

After soaking, the assembly is cooled in a highly controlled manner. Slow cooling is essential to allow the filler metal to solidify properly and to prevent the build-up of thermal stresses within the component, which could lead to cracks or distortion. Once the part is sufficiently cool, the vacuum is released, and the completed assembly can be removed.

Understanding the Trade-offs

While powerful, vacuum brazing is not the right solution for every application. Understanding its advantages and limitations is key to using it effectively.

Primary Advantage: Unmatched Joint Integrity

The clean, flux-free environment produces joints of exceptional strength, purity, and reliability. Vacuum-brazed joints are often hermetic (leak-proof), making them ideal for high-performance applications in aerospace, medical devices, and scientific equipment.

Key Advantage: Superior Material Versatility

Vacuum brazing excels at joining dissimilar materials, such as ceramic-to-metal or copper-to-stainless steel. Since the base materials are not melted, issues of metallurgical incompatibility that plague welding are avoided. It also allows for multiple, complex joints to be made simultaneously in a single furnace cycle.

The Main Limitation: Cost and Cycle Time

Vacuum furnaces represent a significant capital investment, and the process itself is inherently slow. The long heating, soaking, and cooling cycles make it a batch process that is less suited for high-volume, low-cost consumer goods compared to automated welding or torch brazing.

The Need for Precision

The process is less forgiving than other methods. Success depends on meticulous cleaning, precise joint design (clearances), and accurate control over the entire thermal cycle. Any deviation can compromise the quality of the final bond.

Making the Right Choice for Your Application

Selecting the right joining process depends entirely on your project's specific requirements for performance, materials, and cost.

- If your primary focus is maximum strength and hermetic sealing: Vacuum brazing is the superior choice for mission-critical components where failure is not an option.

- If your primary focus is joining dissimilar materials (e.g., steel to ceramic): Vacuum brazing is one of the most effective and reliable methods available.

- If your primary focus is processing complex assemblies with many joints: Vacuum brazing can be highly efficient, as it can bond dozens or even hundreds of joints in a single cycle.

- If your primary focus is high-volume, low-cost production: Faster and more economical processes like automated welding or traditional torch brazing are likely a better fit.

Ultimately, vacuum brazing empowers engineers to create complex, high-integrity components that would otherwise be impossible to manufacture.

Summary Table:

| Aspect | Key Details |

|---|---|

| Process | High-purity joining using filler metal in a vacuum furnace |

| Temperature Range | 800°C to 1150°C |

| Key Benefits | Exceptional strength, clean joints, material versatility |

| Ideal Applications | Aerospace, medical devices, scientific equipment |

| Limitations | Higher cost, longer cycle times, requires precision |

Ready to elevate your material joining with vacuum brazing? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today at #ContactForm to discuss how our tailored solutions can enhance your project's integrity and efficiency!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- What is the purpose of a 1400°C heat treatment for porous tungsten? Essential Steps for Structural Reinforcement

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What tasks does a high-temperature vacuum sintering furnace perform for PEM magnets? Achieve Peak Density