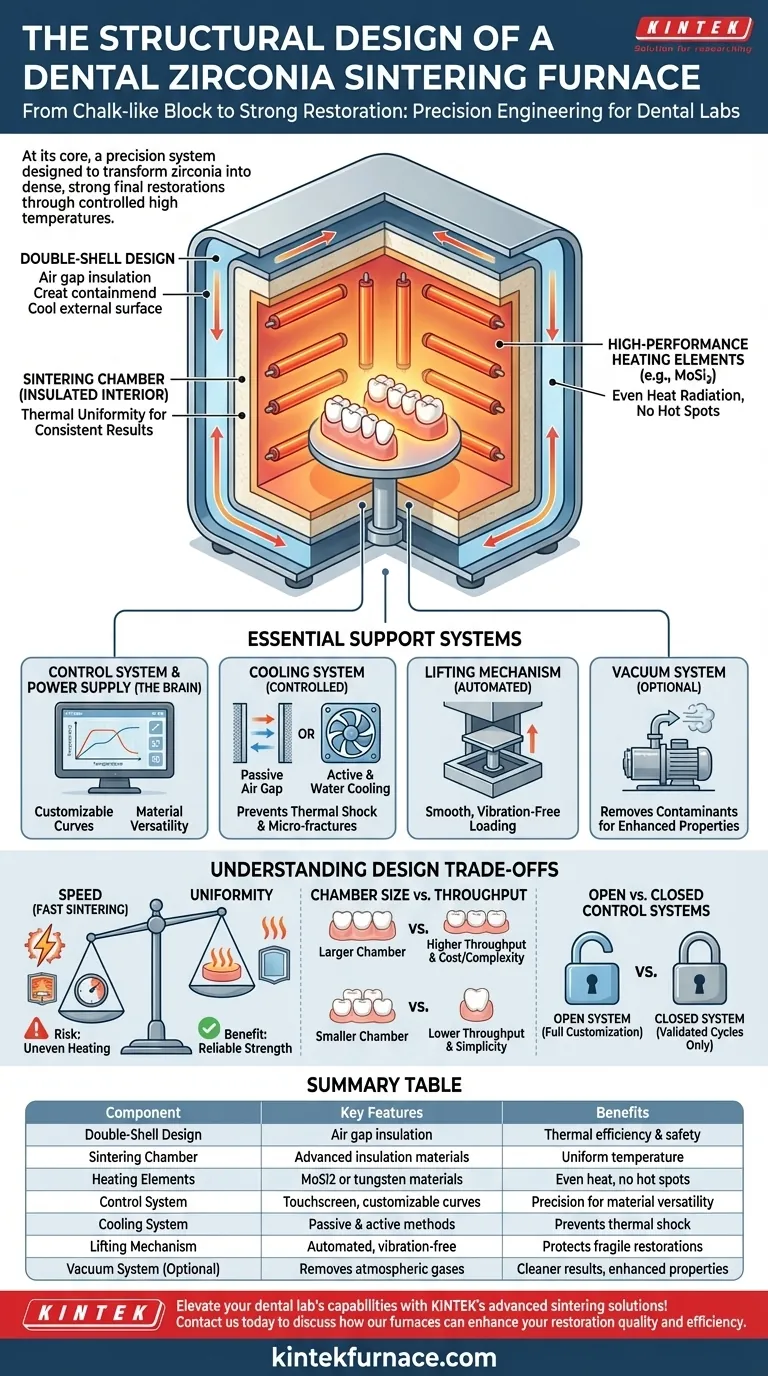

At its core, a dental zirconia sintering furnace is a precision-engineered system designed for a single purpose: to transform a chalk-like zirconia milling block into a dense, translucent, and incredibly strong final restoration. Its structural design consists of a central heating chamber, a furnace body, and a series of critical support systems—including controls, cooling, and power—that all work in unison to manage extreme temperatures with exceptional accuracy.

The design is not merely about generating heat. It's a sophisticated architecture where every component, from the double-shell insulation to the electronic controller, is optimized to ensure the final dental restoration has the precise strength, fit, and aesthetic properties required.

The Core Structure: Furnace Body and Chamber

The physical heart of the furnace is the body and the chamber where the sintering occurs. This structure is foundational to temperature stability and safety.

The Double-Shell Design

Most modern dental furnaces use a double-shell structure. This design creates an air gap between the inner hot chamber and the outer casing.

This feature serves two key purposes: it provides excellent thermal insulation, keeping the heat contained, and it keeps the external surface of the furnace cool to the touch, ensuring operator safety.

The Sintering Chamber

This is the insulated interior where the restorations are placed. It is lined with high-purity, advanced insulation materials like ceramic fiber boards.

The quality of this insulation is critical for achieving thermal uniformity, meaning the temperature is consistent throughout the entire chamber. This ensures all restorations, regardless of their position, are sintered equally.

High-Performance Heating Elements

The heat itself is generated by electric resistance heating elements. These are typically made from materials like Molybdenum Disilicide (MoSi2) or, in some induction models, tungsten.

Their strategic placement within the chamber is a key design factor, engineered to radiate heat evenly and prevent "hot spots" that could compromise the zirconia.

Essential Support Systems

A furnace is more than just a hot box. Its support systems are what provide the precision and reliability needed for clinical success.

The Control System and Power Supply

This is the brain of the furnace. A sophisticated electronic control system, often managed via a touchscreen interface, dictates the entire sintering process.

It allows technicians to execute pre-programmed cycles or create custom temperature curves to match the specific requirements of different zirconia materials (e.g., high-strength vs. high-translucency). This programmability is vital for material versatility.

The Cooling System

Controlled cooling is just as important as controlled heating. The structure incorporates both passive cooling (via the double-shell design) and often active cooling, such as fans or a water cooling system.

A gradual, controlled cool-down prevents thermal shock, which can cause micro-fractures in the final restoration.

The Lifting Mechanism

The furnace door or lift moves the sintering tray into and out of the hot zone. A well-designed furnace features a smooth, vibration-free automated lift.

This prevents any jarring movements that could disturb the fragile pre-sintered restorations and ensures a gradual entry into the high-heat environment.

The Vacuum System (When Present)

Some advanced furnaces incorporate a vacuum system. This is not a universal feature but is used to pump atmospheric gases out of the chamber before heating begins.

Sintering in a vacuum can produce a cleaner result by removing potential contaminants, which may enhance the final material properties for certain applications.

Understanding the Design Trade-offs

The structural design of a furnace reflects a series of engineering trade-offs. Understanding them helps you evaluate different models objectively.

Speed vs. Uniformity

Furnaces marketed for "fast sintering" often have more powerful heating elements and smaller chambers to reach peak temperature quickly. The trade-off is the risk of uneven heating if the control system isn't perfectly calibrated, potentially affecting restoration strength.

Chamber Size vs. Throughput

A larger chamber allows a lab to sinter more units in a single cycle, increasing throughput. However, maintaining perfect thermal uniformity across a larger physical space is more technically demanding and often comes at a higher cost.

Open vs. Closed Control Systems

A key design choice is in the software. An open system allows full customization of sintering cycles for any brand of material. A closed system may restrict you to validated cycles for a specific manufacturer's materials, offering simplicity at the cost of flexibility.

How to Apply This to Your Practice

Choosing a furnace requires matching its structural design to your primary operational goals.

- If your primary focus is high-volume production: Look for a furnace with a larger, well-insulated chamber and a robust design proven to maintain temperature uniformity.

- If your primary focus is material versatility: Prioritize a furnace with an advanced, open control system that allows for fully customizable temperature curves.

- If your primary focus is rapid turnaround on single units: A smaller, specialized "fast-sintering" furnace may be ideal, but verify its design ensures consistent and reliable results.

Understanding this architecture transforms the furnace from a black box into a predictable tool you can strategically select and operate for high-quality outcomes.

Summary Table:

| Component | Key Features | Benefits |

|---|---|---|

| Double-Shell Design | Air gap insulation | Thermal efficiency and operator safety |

| Sintering Chamber | Advanced insulation materials | Uniform temperature distribution |

| Heating Elements | MoSi2 or tungsten materials | Even heat radiation, no hot spots |

| Control System | Touchscreen interface, customizable curves | Precision for material versatility |

| Cooling System | Passive and active methods | Prevents thermal shock and micro-fractures |

| Lifting Mechanism | Automated, vibration-free | Protects fragile restorations during loading |

| Vacuum System (Optional) | Removes atmospheric gases | Cleaner results, enhanced material properties |

Elevate your dental lab's capabilities with KINTEK's advanced sintering solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace expertise. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization to meet your unique experimental needs. Whether you prioritize high-volume production, material versatility, or rapid turnaround, KINTEK delivers reliable, precise results. Contact us today to discuss how our furnaces can enhance your restoration quality and efficiency!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What safety measures should be followed when using a sintering furnace in dental labs? Ensure Safe, High-Quality Dental Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab