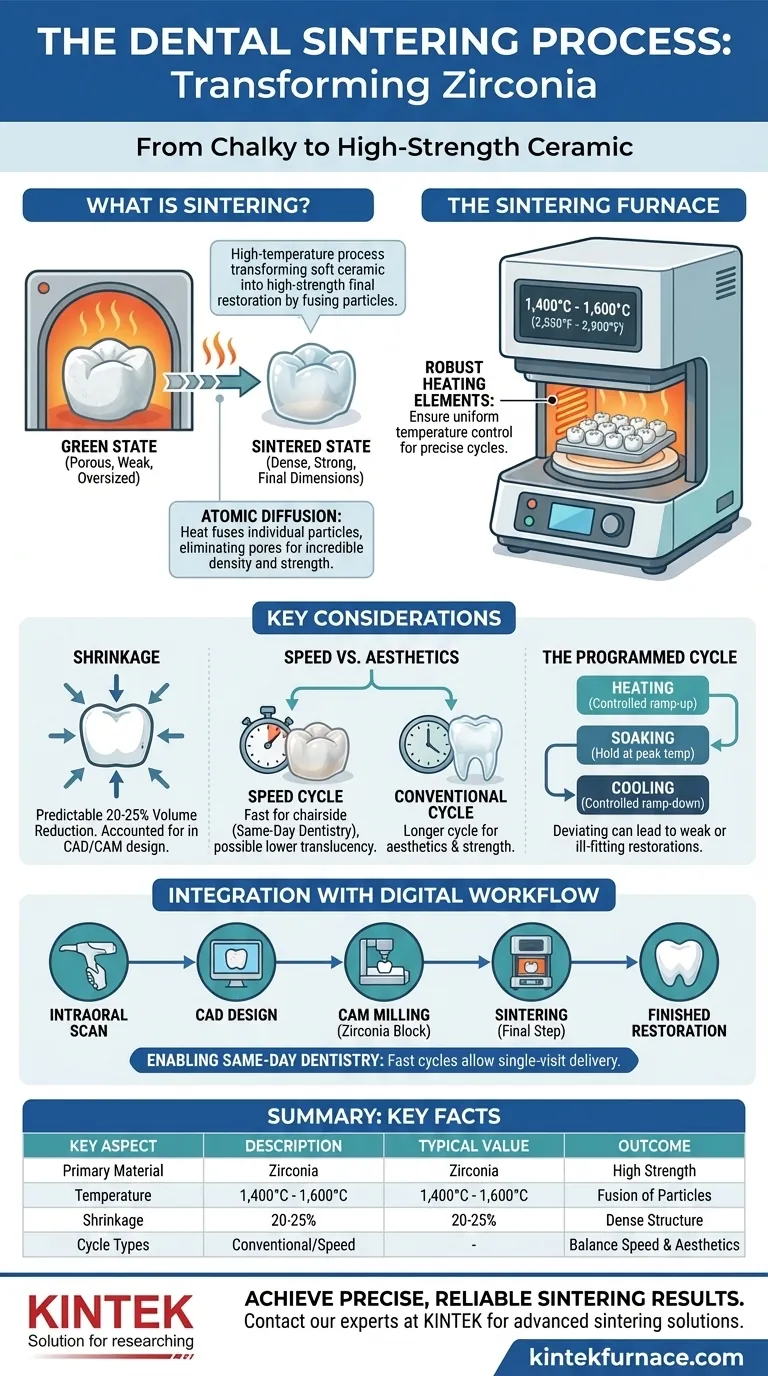

In modern dentistry, sintering is the essential high-temperature process that transforms a soft, chalk-like ceramic restoration into its final, high-strength state. This crucial step primarily applies to zirconia, where it fuses individual material particles together, creating a dense, durable structure ready for placement in a patient's mouth. Without sintering, advanced ceramic materials would lack the strength required for clinical use.

Sintering is not merely a heating process; it is a controlled material transformation. It gives zirconia its renowned strength and durability by consolidating milled particles, but success hinges on precisely managing temperature, time, and the material's inherent shrinkage.

How Sintering Fundamentally Works

The sintering process takes a pre-shaped but fragile material and fundamentally changes its physical properties. It is the final manufacturing step that realizes the potential of the advanced ceramics used in digital dentistry.

From Porous to Solid

Imagine a restoration freshly milled from a zirconia block. In this "green state," it is porous, weak, and oversized. During sintering, intense heat causes the individual ceramic particles to fuse.

This process, known as atomic diffusion, eliminates the pores between particles. As the gaps close, the material becomes incredibly dense and strong, achieving its final desired properties.

The Central Role of Zirconia

Sintering is almost synonymous with zirconia, the most popular material for this process. Zirconia is chosen for its exceptional strength, fracture resistance, and biocompatibility, making it ideal for crowns, bridges, and implant frameworks.

The sintering cycle is tailored to the specific type of zirconia to achieve the right balance of strength and translucency.

The Sintering Furnace

This transformation occurs inside a specialized sintering furnace. These devices are engineered to reach and maintain extremely high temperatures, typically between 1,400°C and 1,600°C (2,550°F and 2,900°F).

They use robust heating elements, often made of molybdenum disilicide, to ensure uniform and precise temperature control throughout the programmed heating and cooling cycle.

Understanding the Key Considerations

While sintering is a reliable process, it involves critical variables that every dental professional must understand to ensure predictable and successful outcomes. Mismanagement of this stage can compromise the entire restoration.

The Challenge of Shrinkage

The most significant factor in sintering is material shrinkage. As the pores between particles are eliminated, the entire restoration shrinks in volume, often by 20-25%.

This is not a flaw but a predictable characteristic. Dental CAD/CAM software automatically calculates this shrinkage, designing and milling an oversized restoration that will sinter down to the perfect final dimensions.

The Speed vs. Aesthetics Trade-off

Modern furnaces offer speed sintering cycles, which can finish a crown in as little as one hour. This is revolutionary for chairside or "same-day" dentistry.

However, there is often a trade-off. Ultra-fast cycles can sometimes result in lower translucency compared to traditional, slower cycles. Technicians must balance the need for speed against the aesthetic demands of the specific case, especially for anterior teeth.

The Importance of a Programmed Cycle

A sintering cycle is more than just heating. It consists of three distinct phases:

- Heating: A controlled ramp-up to the peak temperature.

- Soaking: Holding the restoration at peak temperature for a specific duration.

- Cooling: A controlled ramp-down to prevent thermal shock and internal stress.

Deviating from the manufacturer's prescribed cycle for a specific material can lead to a weak, brittle, or ill-fitting restoration.

The Impact on the Modern Dental Workflow

Sintering is a cornerstone of digital dentistry, directly enabling faster treatment, greater efficiency, and better patient outcomes.

Enabling "Same-Day" Dentistry

The development of rapid sintering cycles is the key technology that allows for the delivery of permanent zirconia restorations in a single visit.

This significantly enhances the patient experience by eliminating the need for temporary crowns and follow-up appointments, providing immediate and durable results.

Integration with Digital Workflows

Sintering is the final step in a fully digital chain that begins with an intraoral scan. The digital file is used to design the restoration (CAD) and then mill it from a zirconia block (CAM).

The milled part is then sintered, completing a seamless and highly precise manufacturing process that integrates perfectly with other digital technologies like 3D printing for models and guides.

Making the Right Choice for Your Goal

Selecting the correct sintering protocol is essential for clinical success and depends entirely on the goal of the restoration.

- If your primary focus is maximum aesthetics and strength: Use a conventional, longer sintering cycle as recommended by the material manufacturer, especially for multi-unit bridges or highly visible anterior crowns.

- If your primary focus is chairside efficiency for single units: Use a validated speed-sintering cycle to enable same-day dentistry and enhance patient convenience.

- If your primary focus is process reliability and consistency: Strictly adhere to the zirconia manufacturer's specific instructions, as each formulation has a unique, optimized sintering profile.

Ultimately, mastering the sintering process is what unlocks the full clinical potential of modern ceramic restorations.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Material | Zirconia (for crowns, bridges, implant frameworks) |

| Typical Temperature Range | 1,400°C to 1,600°C (2,550°F to 2,900°F) |

| Key Outcome | Fuses particles, creating a dense, high-strength structure |

| Critical Factor | Predictable shrinkage (20-25%), accounted for in CAD/CAM design |

| Cycle Types | Conventional (for aesthetics/strength) vs. Speed (for chairside efficiency) |

Achieve precise, reliable sintering results for every dental restoration.

At KINTEK, we understand that the success of your zirconia crowns and bridges depends on a perfectly controlled sintering process. Our advanced high-temperature furnaces are engineered to deliver the uniform heating and precise temperature profiles required for both conventional and speed-sintering cycles.

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides dental labs with robust sintering solutions. Our product line, including Vacuum & Atmosphere Furnaces, is complemented by strong deep customization capability to precisely meet your lab's unique workflow requirements, ensuring consistent, high-quality results case after case.

Ready to enhance your lab's capabilities? Contact our experts today to find the ideal sintering furnace for your dental laboratory.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the effects of overloading a dental sintering furnace? Ensure Predictable, High-Quality Zirconia Restorations

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures