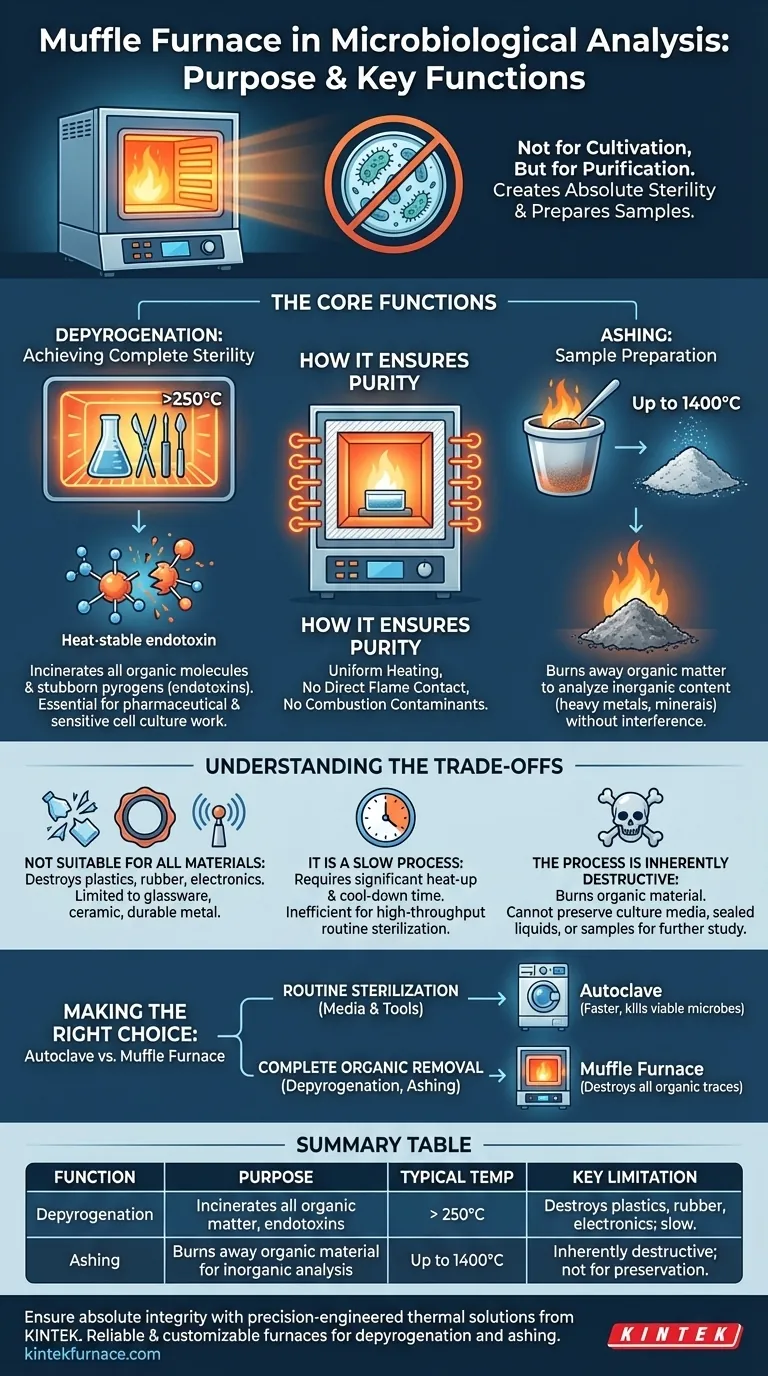

In microbiological analysis, a muffle furnace is not for cultivating organisms, but for creating a state of absolute sterility and preparing samples for specific tests. Its primary purposes are the complete destruction of all biological material—including bacteria, viruses, and heat-resistant endotoxins—from glassware and tools (a process called depyrogenation), and the ashing of samples to precisely analyze their inorganic content.

While a standard autoclave sterilizes by killing microbes, a muffle furnace purifies by incinerating all organic matter entirely. This distinction is critical for advanced applications where even the remnants of dead cells can interfere with results.

The Core Functions in a Microbiology Lab

The extreme temperatures of a muffle furnace, often exceeding 500°C and reaching up to 1400°C, serve two distinct and critical purposes that standard lab equipment cannot fulfill.

Achieving Complete Sterility (Depyrogenation)

An autoclave is effective for routine sterilization, using steam around 121°C to kill viable microorganisms. However, it does not reliably destroy pyrogens, such as endotoxins, which are heat-stable molecules from bacterial cell walls that can cause fever if introduced into the body.

A muffle furnace performs depyrogenation by heating glassware and metal instruments to temperatures above 250°C. This intense dry heat incinerates all organic molecules, including stubborn pyrogens, rendering the equipment not just sterile but also chemically inert. This is essential for pharmaceutical work and sensitive cell culture applications.

Sample Preparation via Ashing

Many analyses in environmental or food microbiology require measuring the inorganic components of a sample, such as heavy metals or mineral content. The presence of organic matter—cells, proteins, and other biological material—interferes with these tests.

Ashing is the process of placing a sample in a muffle furnace and heating it until all organic and volatile compounds burn away. The only material left behind is the inorganic ash, which can then be accurately weighed and analyzed without biological interference.

How it Ensures Purity

A key feature of a muffle furnace is its design. The sample is placed in an insulated chamber ("muffle") that is heated externally. This means the material is heated to a uniform temperature without any direct contact with a flame or its combustion contaminants. This isolation is crucial for maintaining the purity of the sample during both depyrogenation and ashing.

Understanding the Trade-offs

While powerful, a muffle furnace is a specialized tool and not a replacement for other sterilization methods. Understanding its limitations is key to using it correctly.

Not Suitable for All Materials

The extreme temperatures will destroy any plastic components, damage rubber seals, and ruin most electronic sensors. Its use is almost exclusively limited to glassware, ceramic, and durable metal instruments.

It Is a Slow Process

Unlike a rapid autoclave cycle, a muffle furnace requires significant time to heat up to its target temperature and, just as importantly, to cool down safely. A complete cycle can take several hours, making it inefficient for high-throughput, routine sterilization.

The Process is Inherently Destructive

The function of a muffle furnace is to burn and destroy organic material. It cannot be used to sterilize things you wish to preserve, such as culture media, sealed liquids, or biological samples you intend to study further. Its purpose is purification through destruction.

Making the Right Choice for Your Goal

Selecting the correct thermal process depends entirely on your analytical objective. The key is to distinguish between the need for sterility and the need for complete organic removal.

- If your primary focus is routine sterilization of media and tools: Use an autoclave, as it is faster and sufficient for killing viable microbes in most applications.

- If your primary focus is eliminating all organic traces, including endotoxins, from glassware: Use a muffle furnace for depyrogenation, especially for pharmaceutical or sensitive research.

- If your primary focus is analyzing the inorganic mineral or metal content of a sample: Use a muffle furnace for ashing to burn away all interfering organic matter.

Understanding this distinction empowers you to select the precise tool needed to ensure the absolute integrity of your microbiological work.

Summary Table:

| Function | Purpose | Typical Temperature | Key Limitation |

|---|---|---|---|

| Depyrogenation | Incinerates all organic matter, including heat-resistant endotoxins, from glassware/tools. | > 250°C | Destroys plastics, rubber, and electronics; slow process. |

| Ashing | Burns away organic material from samples to analyze inorganic content (e.g., heavy metals). | Up to 1400°C | Inherently destructive; not for preserving samples. |

Ensure the absolute integrity of your microbiological analysis with precision-engineered thermal solutions from KINTEK.

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, and Vacuum Furnaces, is complemented by strong deep customization capability to precisely meet your unique experimental requirements for depyrogenation and ashing.

Contact us today to discuss how our reliable and customizable furnaces can enhance the purity and accuracy of your lab's work.

Get in Touch for a Custom Solution

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination