At its core, vacuum annealing is a high-precision heat treatment process performed inside a sealed chamber where the atmospheric gases have been removed. The material is heated to a specific temperature, held for a duration to allow its internal structure to realign, and then cooled in a controlled manner, all while maintained under a vacuum. This process fundamentally alters the material's properties by removing internal stresses and preventing surface reactions.

The critical advantage of performing annealing in a vacuum is the elimination of atmospheric gases. This prevents surface oxidation and contamination, resulting in superior material purity, enhanced mechanical properties, and a clean finish that is often impossible to achieve with conventional methods.

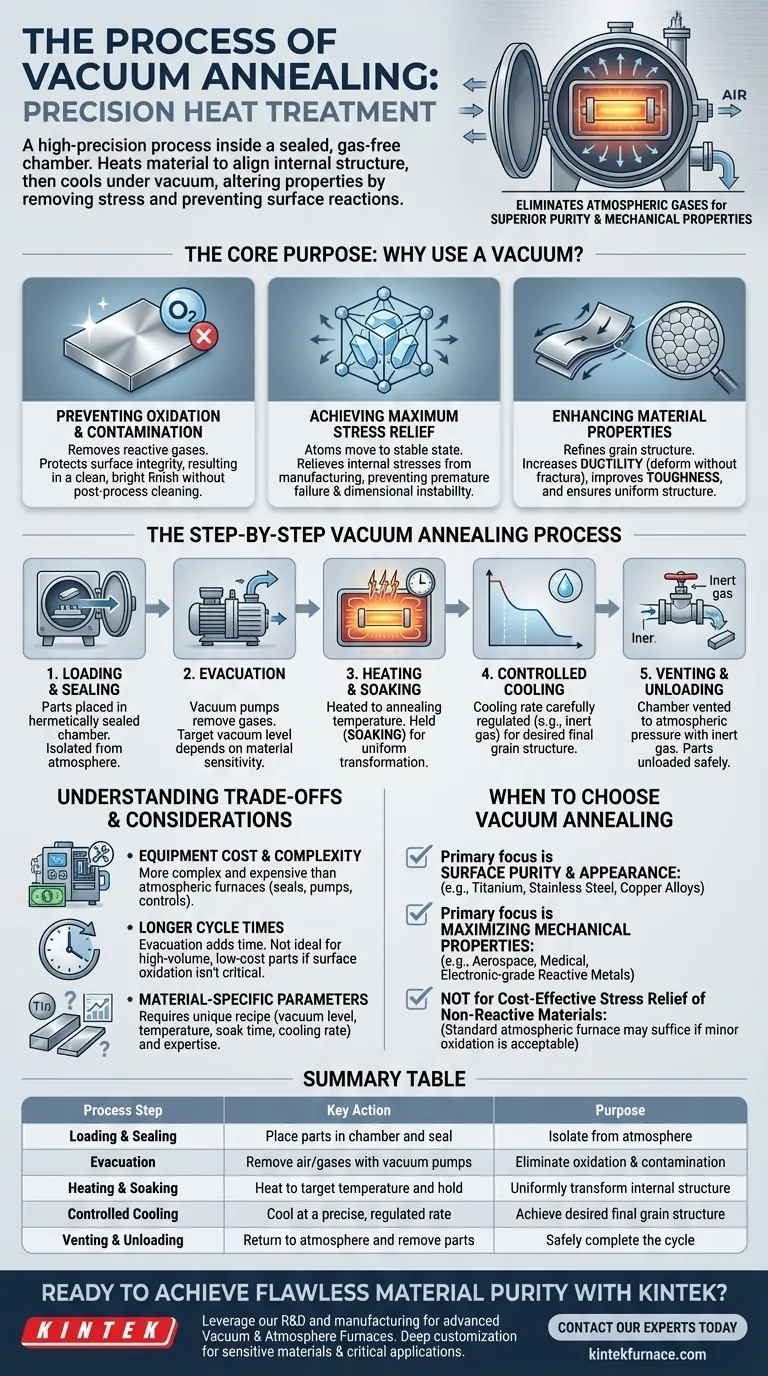

The Core Purpose: Why Use a Vacuum?

Annealing is a foundational metallurgical process. Performing it in a vacuum elevates its effectiveness, particularly for sensitive or high-performance materials.

Preventing Oxidation and Contamination

In a standard atmosphere, heating a metal invites oxygen and other reactive gases to bond with its surface, forming an undesirable oxide layer.

A vacuum furnace removes these reactive gases. This protects the material's surface integrity, resulting in a clean, bright finish without the need for post-process cleaning.

Achieving Maximum Stress Relief

All manufacturing processes, from machining to welding, introduce residual stress into a material's crystal structure. These stresses can lead to premature failure or dimensional instability.

Heating the material gives its atoms the energy to move into a more stable, lower-energy state, relieving this stress. The vacuum environment ensures this process happens cleanly, without introducing new impurities or surface defects that could create new stress points.

Enhancing Material Properties

By relieving internal stresses and refining the grain structure, vacuum annealing significantly improves key mechanical properties.

This typically includes increased ductility (the ability to deform without fracturing), improved toughness, and a more uniform and predictable crystalline structure throughout the component.

The Step-by-Step Vacuum Annealing Process

While specific parameters vary by material, the operational sequence follows a distinct and highly controlled progression. Modern furnaces use Programmable Logic Controllers (PLCs) to automate these steps with high precision.

Step 1: Loading and Sealing

The material or components are loaded into the furnace chamber. The chamber is then hermetically sealed to create a closed system, isolating it from the outside atmosphere.

Step 2: Evacuation

A system of vacuum pumps removes the air and other gases from the sealed chamber. The target vacuum level depends on the material's sensitivity to oxidation; more reactive metals require a higher vacuum.

Step 3: Heating and Soaking

Once the target vacuum is reached, electric heating elements raise the chamber's temperature to the specified annealing point. The material is held at this temperature—a phase known as soaking—for a predetermined time to ensure the entire part is uniformly heated and its internal structure has transformed.

Step 4: Controlled Cooling

After soaking, the heating elements are turned off, and the material is allowed to cool. The cooling rate is critical and carefully controlled, often assisted by inert gas backfilling or regulated cooling systems, to achieve the desired final grain structure and properties.

Step 5: Venting and Unloading

Once the material has cooled to a safe temperature, the vacuum is released by venting the chamber, typically with an inert gas like nitrogen or argon, to return it to atmospheric pressure. The chamber can then be opened and the finished parts unloaded.

Understanding the Trade-offs and Considerations

Vacuum annealing is a powerful tool, but it is not the universal solution for all heat treatment needs. Understanding its limitations is key to using it effectively.

Equipment Cost and Complexity

Vacuum furnaces are significantly more complex and expensive to purchase and maintain than standard atmospheric furnaces. The need for robust seals, powerful pumps, and sophisticated control systems drives up the initial investment.

Longer Cycle Times

The evacuation step adds considerable time to the beginning of each cycle. For high-volume, low-cost parts where surface oxidation is not a critical concern, the time penalty may not be justifiable.

Material-Specific Parameters

The process is not "one-size-fits-all." Each material requires a unique recipe of vacuum level, temperature, soak time, and cooling rate to achieve optimal results. This demands significant process development and expertise.

When to Choose Vacuum Annealing

Your decision should be driven by the final requirements of your component.

- If your primary focus is surface purity and appearance: Vacuum annealing is the superior choice to prevent oxidation on sensitive materials like titanium, stainless steel, and copper alloys.

- If your primary focus is maximizing the mechanical properties of reactive metals: The pure environment of a vacuum is essential for achieving the highest levels of stress relief and ductility in aerospace, medical, or electronic-grade materials.

- If your primary focus is cost-effective stress relief for non-reactive materials: A standard atmospheric furnace may be sufficient and more economical, provided a small amount of surface oxidation is acceptable.

Ultimately, vacuum annealing is a precision process chosen when material integrity and surface quality cannot be compromised.

Summary Table:

| Process Step | Key Action | Purpose |

|---|---|---|

| Loading & Sealing | Place parts in chamber and seal | Isolate from atmosphere |

| Evacuation | Remove air/gases with vacuum pumps | Eliminate oxidation & contamination |

| Heating & Soaking | Heat to target temperature and hold | Uniformly transform internal structure |

| Controlled Cooling | Cool at a precise, regulated rate | Achieve desired final grain structure |

| Venting & Unloading | Return to atmosphere and remove parts | Safely complete the cycle |

Ready to achieve flawless material purity and performance with precision vacuum annealing?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced vacuum furnace solutions tailored to your unique requirements. Our product line includes high-performance Vacuum & Atmosphere Furnaces, complemented by our strong deep customization capability to precisely meet the demands of your sensitive materials and critical applications.

Contact our experts today to discuss how our vacuum annealing solutions can enhance your material properties and protect your components from oxidation.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today