In essence, the MPCVD method uses microwave energy to create a highly active, clean plasma from a gas mixture, which is an exceptionally efficient environment for depositing high-quality diamond films onto a substrate. This process is favored over other techniques because it avoids common sources of contamination while offering superior control, stability, and speed.

MPCVD's true advantage lies in its ability to generate a dense, stable plasma without direct contact from heating elements. This "contactless" heating method is the key to minimizing impurities and achieving reproducible, high-purity diamonds at impressive growth rates.

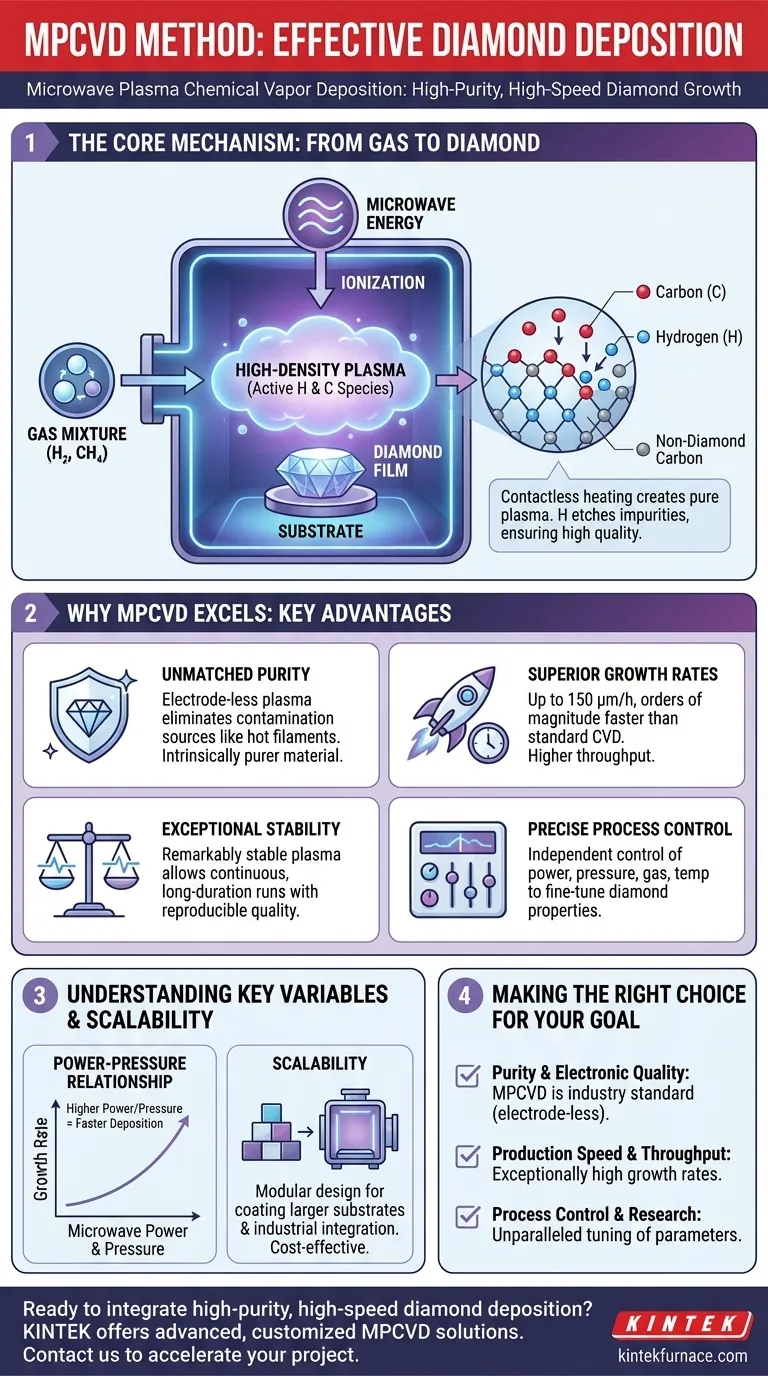

The Core Mechanism: From Gas to Diamond

The MPCVD process is a sophisticated yet elegant method that transforms simple gases into one of the hardest materials known. The entire operation takes place within a controlled vacuum chamber.

Step 1: Creating the Plasma

The process begins by introducing a gas mixture, typically containing hydrogen and a carbon source like methane, into the chamber. Microwave energy is then directed into the chamber.

This energy field causes free electrons within the gas to oscillate violently, leading to a cascade of collisions with gas atoms and molecules. This intense activity strips electrons from the atoms, ionizing the gas and transforming it into a glowing, chemically active plasma.

Step 2: The Deposition Environment

The resulting plasma is a high-density soup of supersaturated hydrogen and carbon-containing atomic groups. Unlike other methods, the plasma is generated without electrodes or hot filaments inside the chamber, a critical feature for purity.

The substrate, where the diamond will grow, rests on a holder within this plasma.

Step 3: Diamond Film Growth

The highly active carbon species in the plasma deposit onto the substrate surface, arranging themselves into the crystal lattice structure of diamond. The high concentration of atomic hydrogen in the plasma plays a crucial role by selectively etching away any non-diamond carbon (like graphite), ensuring the growing film is of high quality.

Why MPCVD Excels for Diamond Synthesis

The effectiveness of MPCVD is not due to a single factor, but a combination of advantages that directly address the common challenges of diamond synthesis.

Unmatched Purity and Quality

The defining feature of MPCVD is its electrode-less nature. Methods that use hot filaments or electrodes risk having those components degrade and introduce metallic or other contaminants into the diamond film. MPCVD completely sidesteps this problem, leading to intrinsically purer material.

Exceptional Stability and Reproducibility

The plasma generated by microwaves is remarkably stable and can be maintained for extended periods. This allows for continuous, long-duration growth runs without a decline in quality. For any industrial or high-volume application, this reproducibility is non-negotiable.

Superior Growth Rates and Efficiency

MPCVD systems can achieve growth rates as high as 150 µm/h. This is orders of magnitude faster than some standard CVD processes that operate closer to 1 µm/h. This speed directly translates to higher throughput and lower operational costs per carat.

Precise Process Control

Operators can precisely and independently control key variables like substrate temperature, gas mixture composition, and microwave power. This high degree of control allows for fine-tuning the properties of the diamond, from its grain size to its electronic properties, making it suitable for a wide range of applications.

Understanding the Key Variables

While robust, the MPCVD process is governed by a few key parameters that must be managed to achieve desired results.

The Power-Pressure Relationship

The growth rate is directly influenced by both the microwave power and the chamber pressure. Increasing these variables enhances the ionization and density of the plasma, which in turn increases the concentration of active species available for diamond growth. This accelerates the deposition rate significantly.

Scalability for Industrial Use

Modern MPCVD systems are designed to be modular and scalable. This allows the technology to be adapted for coating larger substrates or for integration into larger industrial production lines, making it a commercially viable choice, not just a laboratory curiosity.

Cost-Effectiveness

When considering the combination of high growth rates, high purity (reducing post-processing), and long-term stability, MPCVD is often more cost-effective than competing CVD diamond-coating techniques for high-performance applications.

Making the Right Choice for Your Goal

Selecting a deposition method depends entirely on your end goal. MPCVD offers a powerful solution tailored for applications where quality and efficiency are paramount.

- If your primary focus is material purity and electronic quality: MPCVD is the industry standard, as its electrode-less design eliminates a primary source of contamination.

- If your primary focus is production speed and throughput: MPCVD's exceptionally high and stable growth rates make it a clear choice for efficient, high-volume manufacturing.

- If your primary focus is process control and research: The ability to precisely tune gas mixtures, power, and temperature gives researchers unparalleled control to develop novel diamond materials.

Ultimately, MPCVD provides a robust and controllable pathway to producing high-quality synthetic diamond for demanding technological applications.

Summary Table:

| Key Advantage | MPCVD Benefit |

|---|---|

| Purity | Electrode-less plasma eliminates contamination sources (e.g., from filaments/electrodes). |

| Growth Rate | Achieves rates up to 150 µm/h, far exceeding many other CVD methods. |

| Control & Reproducibility | Precise, independent control over power, pressure, and gas mixtures for consistent results. |

| Scalability | Modular design supports coating larger substrates and integration into production lines. |

Ready to integrate high-purity, high-speed diamond deposition into your R&D or production line?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing capabilities to provide advanced, high-temperature furnace solutions. Our expertise in MPCVD and other CVD/PECVD systems is complemented by strong deep customization capabilities to precisely meet your unique experimental and production requirements.

Contact us today to discuss how our tailored solutions can accelerate your diamond synthesis projects. ➡️ Get in Touch

Visual Guide

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What are the advantages of CVD tube furnace sintering systems? Achieve Superior Material Control and Purity

- What is the process for synthesizing transition metal dichalcogenides (TMDs) using CVD tube furnaces? Master High-Quality Thin Film Growth

- Why are advanced materials and composites important? Unlock Next-Gen Performance in Aerospace, Auto, and More

- What future trends are expected in the development of CVD tube furnaces? Discover Smarter, More Versatile Systems

- What are the operational benefits of using a CVD Tube Furnace? Enhance Precision and Efficiency in Your Lab