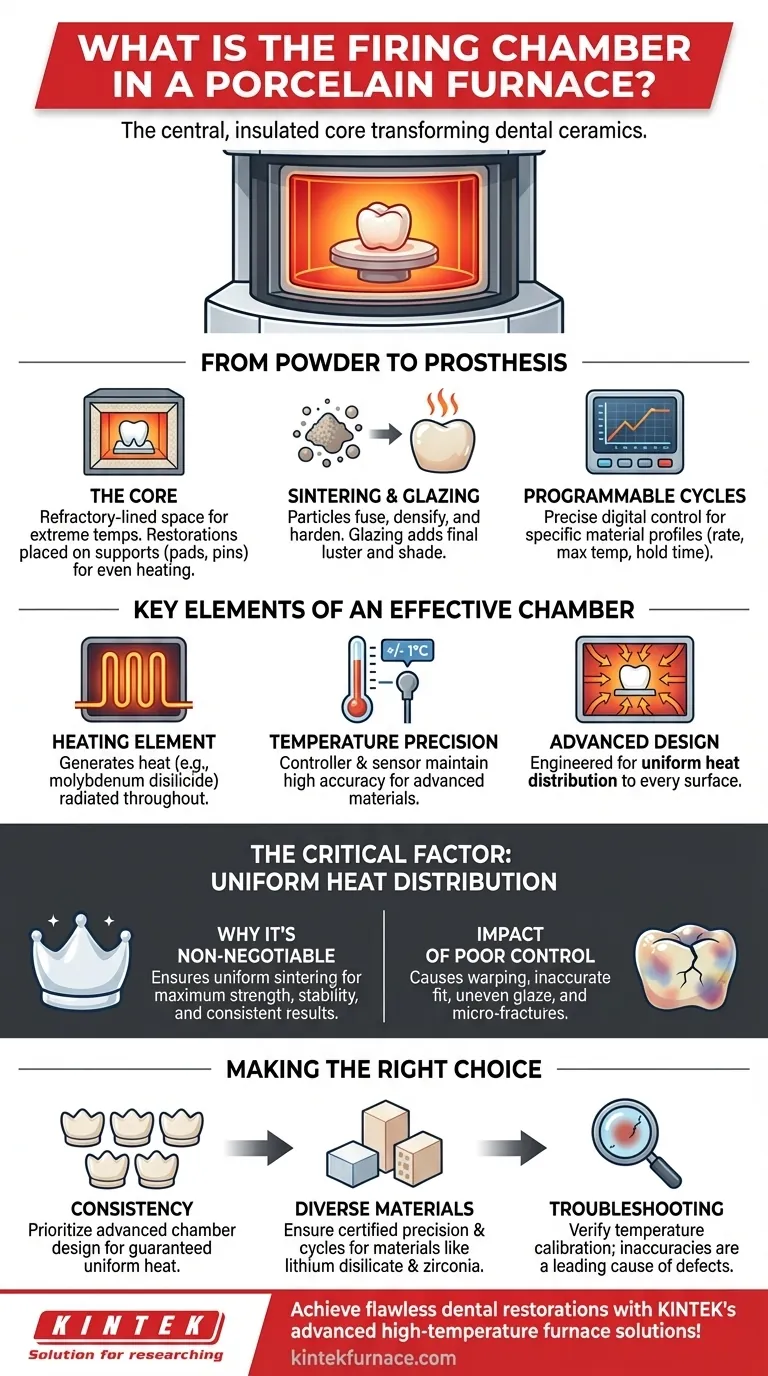

In simple terms, the firing chamber is the central, insulated core of a dental porcelain furnace where ceramic restorations are placed to be heated. It is the principal unit that transforms delicate porcelain powder or milled blocks into a strong, aesthetic, and final dental prosthesis through a highly controlled thermal process.

The quality of a porcelain restoration is not determined by heat alone, but by the firing chamber's ability to deliver uniform temperature with absolute precision. Understanding its function is the key to achieving consistent, predictable, and high-quality clinical results.

The Firing Chamber: From Powder to Prosthesis

The firing chamber is where the critical transformation of dental ceramics occurs. Its design and operation directly dictate the final physical and esthetic properties of a crown, veneer, or bridge.

The Core of the Furnace

The chamber is a refractory-lined space designed to withstand and contain extreme temperatures. Inside, restorations are carefully placed on specialized supports like firing pads, pins, or mesh trays to ensure they are heated evenly and without distortion.

The Sintering and Glazing Process

Once the furnace door is sealed, the chamber's temperature is gradually increased according to a specific program. This process, known as firing or sintering, causes the ceramic particles to fuse, densify, and harden. Subsequent cycles can be used for glazing or crystallization to achieve the final surface luster and shade.

The Role of Programmable Cycles

Modern furnaces use digital programs to precisely control the environment inside the chamber. Dental technicians select pre-set or custom cycles tailored to the specific ceramic material being used, dictating the rate of temperature increase, the maximum temperature, and the holding time.

Key Elements of an Effective Firing Chamber

A high-performance firing chamber is more than just a hot box. It is an integrated system of components working together to achieve absolute precision.

The Heating Element

The heat itself is generated by one or more heating elements, often made of a durable material like molybdenum disilicide. These elements are strategically placed to radiate heat throughout the chamber.

Temperature Precision

The system is governed by a temperature controller and sensor that maintains accuracy often within +/- 1 degree Celsius. This precision is not a luxury; it is essential for meeting the strict firing parameters of advanced ceramic materials.

Advanced Chamber Design

The internal shape and construction of the chamber are engineered for one primary goal: uniform heat distribution. This ensures that every surface of the restoration—from the thin incisal edge to the thicker margin—receives the exact same thermal exposure.

Understanding the Critical Factor: Uniform Heat Distribution

The single most important function of a firing chamber is to provide even, consistent heat. Any deviation can compromise the integrity and appearance of the final restoration.

Why Even Temperature is Non-Negotiable

If one part of a restoration gets hotter than another, it can lead to internal stresses, warping, or an inaccurate fit. Consistent temperature ensures that the entire ceramic structure sinters uniformly, resulting in maximum strength and stability.

The Impact of Poor Temperature Control

A firing chamber with poor temperature distribution is a primary source of defects. This can manifest as uneven glaze, blotchy coloration, micro-fractures, or a prosthesis that simply does not fit the patient correctly.

Making the Right Choice for Your Goal

Understanding the firing chamber helps you evaluate furnace performance and troubleshoot common issues.

- If your primary focus is consistency across multiple units: Prioritize furnaces with documented advanced chamber designs that explicitly guarantee uniform heat distribution.

- If your primary focus is working with diverse modern ceramics: Ensure the furnace's temperature precision and programmable cycles are certified to match the specific requirements of materials like lithium disilicate or zirconia.

- If your primary focus is troubleshooting failed restorations: Begin your investigation by verifying the furnace's temperature calibration, as chamber inaccuracies are a leading cause of defects.

Ultimately, mastering the principles of the firing chamber empowers you to achieve flawless esthetic results with every restoration.

Summary Table:

| Key Aspect | Description |

|---|---|

| Function | Central insulated core for heating ceramic restorations via sintering and glazing processes. |

| Temperature Precision | Maintains accuracy within +/- 1°C for consistent material properties. |

| Heat Distribution | Engineered for uniform heating to prevent defects like warping or discoloration. |

| Programmable Cycles | Digital controls for tailored temperature profiles based on ceramic materials. |

Achieve flawless dental restorations with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with precision-engineered products like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures your unique experimental needs are met for consistent, high-quality results. Contact us today to elevate your lab's performance!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Spark Plasma Sintering SPS Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations