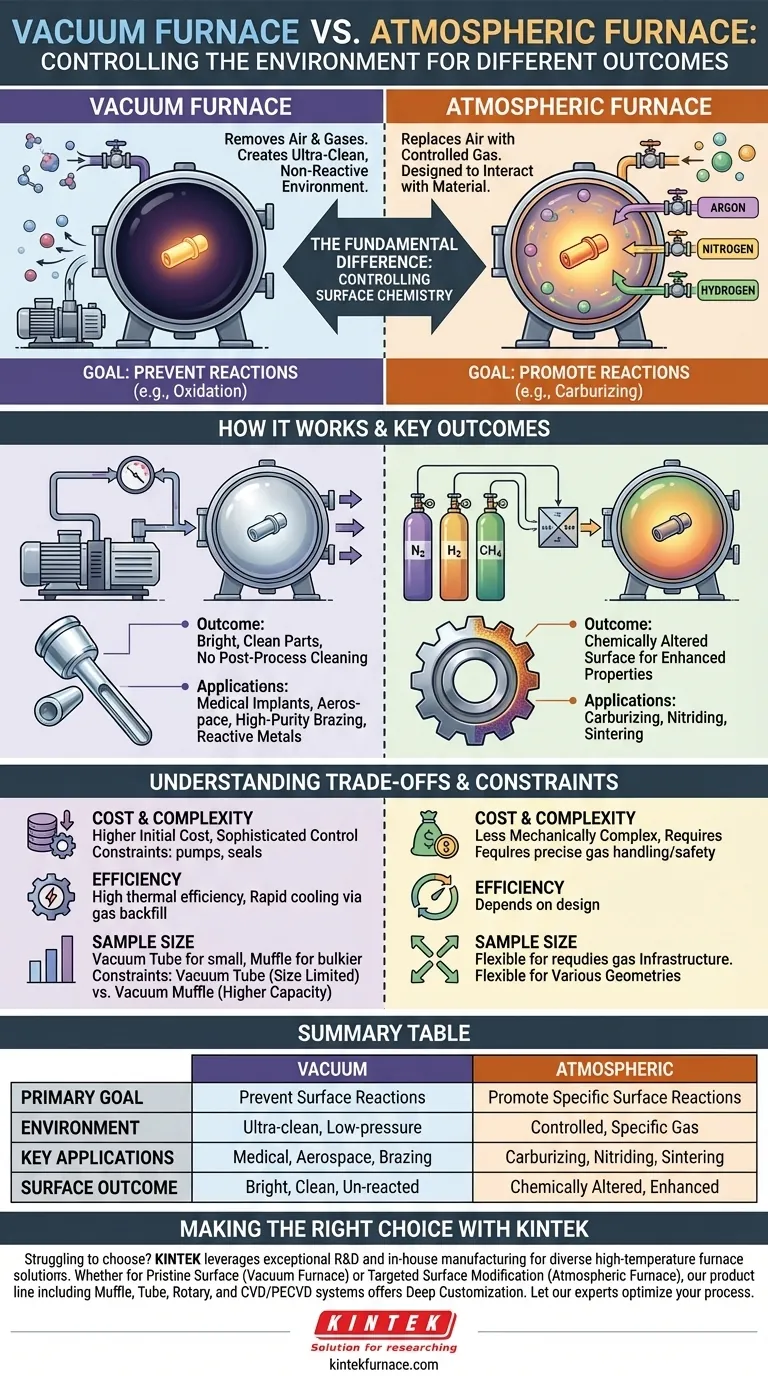

At its core, the difference between a vacuum furnace and an atmospheric furnace is the environment in which the material is heated. A vacuum furnace removes air and other gases to create an ultra-clean, non-reactive environment. In contrast, an atmospheric furnace replaces the ambient air with a specific, carefully controlled gas or mixture of gases designed to interact with the material's surface in a predictable way.

The choice is not simply about heating a part, but about controlling its surface chemistry. A vacuum furnace is used to prevent reactions like oxidation, while an atmospheric furnace is used to promote specific, desirable reactions.

The Fundamental Difference: Controlling the Environment

The primary function that separates these two technologies is how they manage the atmosphere surrounding the workpiece during a thermal cycle. This control, or lack thereof, dictates the final properties of the material.

How a Vacuum Furnace Works

A vacuum furnace uses a system of pumps to evacuate nearly all molecules of air and other gases from a sealed heating chamber before the process begins. This creates a low-pressure, or vacuum, environment.

The purpose is to create a chemically inert environment. By removing oxygen, water vapor, and other potential contaminants, the furnace prevents unwanted chemical reactions on the material's surface at elevated temperatures.

How an Atmospheric Furnace Works

An atmospheric furnace, more accurately called a controlled-atmosphere furnace, also works with a sealed chamber. However, instead of removing the atmosphere, it purges the ambient air and replaces it with a specific gas.

This gas can be inert (like argon or nitrogen) to simply prevent oxidation, or it can be reactive (like hydrogen, nitrogen mixtures, or carbon-rich gases). This allows for processes that intentionally alter the surface of the material, such as carburizing or nitriding.

Key Process Outcomes and Applications

The difference in atmospheric control leads to vastly different applications. Your choice depends entirely on what you want to happen to your material's surface during heating.

When to Use a Vacuum Furnace: Surface Purity

Vacuum furnaces are the standard for processes where maintaining the pristine surface of the material is critical. The absence of an atmosphere prevents oxidation, decarburization, and other forms of surface contamination.

This results in bright, clean parts that require little to no post-process cleaning. Common applications include the heat treatment of medical implants, aerospace components, high-purity brazing, and annealing of reactive metals.

When to Use an Atmospheric Furnace: Surface Modification

Atmospheric furnaces are chosen when the goal is to intentionally change the material's surface chemistry to enhance its properties. The controlled gas atmosphere is a key ingredient in the process itself.

Processes like carburizing (adding carbon to steel for hardness), nitriding (adding nitrogen for wear resistance), and sintering of powdered metals rely on specific gas-to-solid reactions that can only occur in a controlled-atmosphere environment.

Understanding the Trade-offs and Constraints

While function is the main driver, practical considerations like cost, efficiency, and physical limitations also influence the decision.

Cost and Complexity

Vacuum furnaces are generally more complex and carry a higher initial cost due to the robust vacuum pumps, advanced sealing mechanisms, and sophisticated control systems required to achieve and maintain a vacuum.

Atmospheric furnaces can be less mechanically complex, but require precise gas-handling infrastructure, including flow controllers, mixers, and safety systems, especially when using flammable or reactive gases.

Process Speed and Efficiency

Modern vacuum furnaces often have high thermal efficiency and can achieve very rapid cooling. This is accomplished by backfilling the hot chamber with a high-pressure inert gas (like nitrogen or argon) and circulating it with a fan to quench the parts.

Sample Size and Geometry

Within the vacuum category, constraints exist. Vacuum tube furnaces are excellent for precision work on smaller items but are limited by their diameter and length. For bulkier components, a vacuum muffle furnace offers significantly more internal capacity and often a higher maximum temperature.

Making the Right Choice for Your Process

Selecting the correct furnace technology begins with a clear understanding of your end goal for the material.

- If your primary focus is preserving the material's surface integrity: A vacuum furnace is the superior choice for a clean, bright, and un-reacted finish.

- If your primary focus is altering the surface chemistry of the material: An atmospheric furnace is required to introduce the specific gases needed for processes like carburizing or nitriding.

- If you are processing highly reactive metals like titanium or zirconium: A vacuum furnace provides the most inert and non-contaminating environment possible.

- If your budget is tight and your process can tolerate a simple inert atmosphere: A nitrogen or argon-based atmospheric furnace can be a cost-effective alternative to vacuum for preventing basic oxidation.

Ultimately, your decision hinges on whether you need to protect the surface or change it.

Summary Table:

| Feature | Vacuum Furnace | Atmospheric Furnace |

|---|---|---|

| Primary Goal | Prevent surface reactions (oxidation) | Promote specific surface reactions (carburizing, nitriding) |

| Environment | Ultra-clean, low-pressure vacuum | Controlled, specific gas atmosphere |

| Key Applications | Medical implants, aerospace, brazing, reactive metals | Carburizing, nitriding, sintering |

| Surface Outcome | Bright, clean, un-reacted finish | Chemically altered surface for enhanced properties |

Struggling to choose the right furnace for your specific thermal process?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced high-temperature furnace solutions. Whether your priority is the pristine surface integrity achieved with a Vacuum Furnace or the targeted surface modification enabled by an Atmospheric Furnace, our product line—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is backed by strong deep customization capabilities to precisely meet your unique experimental requirements.

Let our experts help you optimize your process. Contact us today for a personalized consultation!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How do atmosphere furnaces contribute to ceramic manufacturing? Enhance Purity and Performance

- How is the sealing performance of an experimental box type atmosphere furnace enhanced? Boost Purity with Advanced Sealing Systems

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance