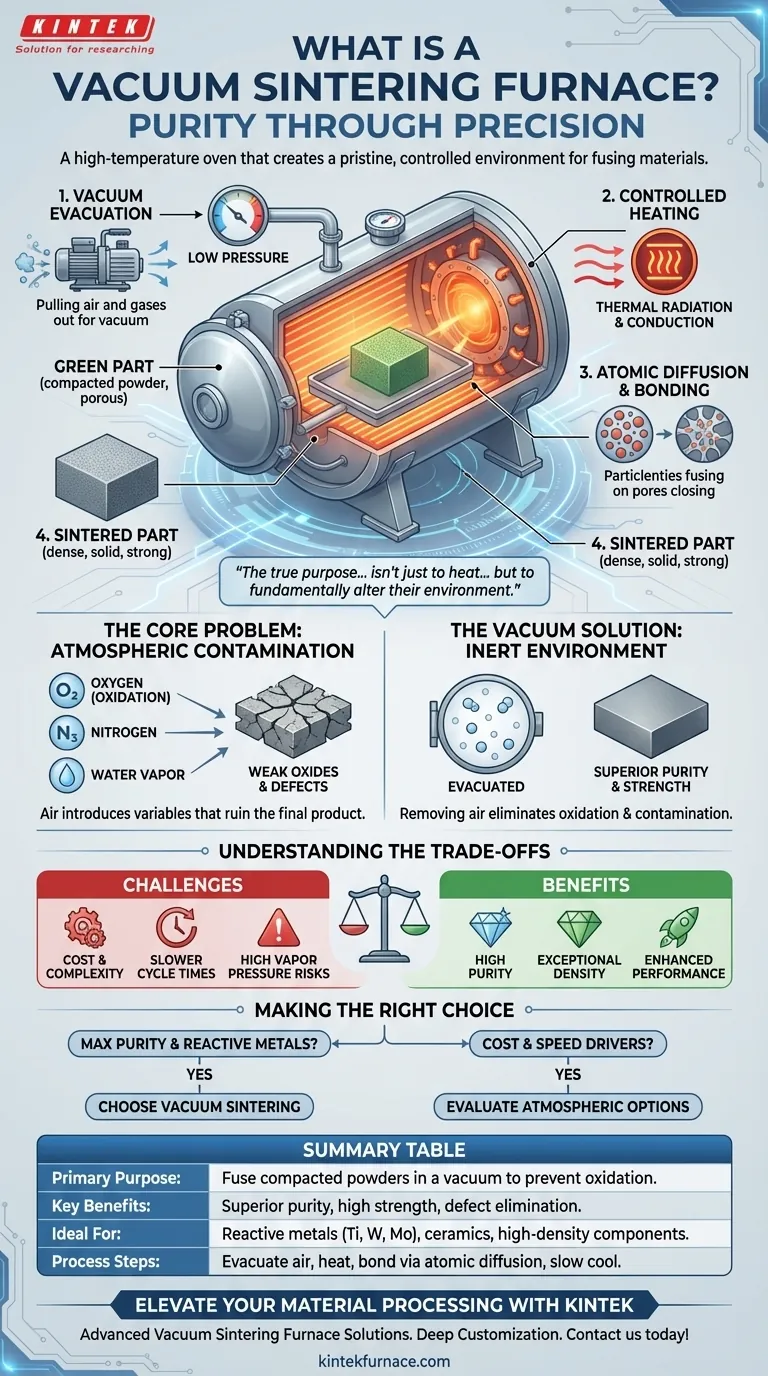

In essence, a vacuum sintering furnace is a high-temperature oven that creates a pristine, controlled environment for fusing materials together. Its primary purpose is to heat compacted powders, such as metals or ceramics, to just below their melting point within a vacuum. This process, called sintering, bonds the particles into a solid, dense object while the vacuum prevents unwanted chemical reactions like oxidation, resulting in a final product with superior purity and strength.

The true purpose of a vacuum sintering furnace isn't just to heat materials, but to fundamentally alter their environment. By removing air, it eliminates oxidation and contamination, allowing for the creation of high-purity, high-performance components from materials that would otherwise be compromised.

The Core Problem: Why Sintering Needs a Vacuum

Sintering is a delicate thermal process. Simply heating materials in the open air introduces variables that can ruin the final product. A vacuum furnace is designed to control these variables with precision.

The Enemy of High Temperatures: Oxidation

At the high temperatures required for sintering, most metals are highly reactive with oxygen in the air. This reaction forms brittle, weak oxides on the surface of the material's particles, preventing them from bonding properly and severely degrading the final component's structural integrity.

A vacuum furnace solves this by physically removing the air—and thus the oxygen—from the chamber before heating begins.

The Challenge of Purity

Beyond just oxygen, the air contains nitrogen, water vapor, and other trace gases. These elements can act as contaminants, becoming trapped within the material's structure during sintering.

This contamination creates internal defects and voids, weakening the material and altering its intended mechanical, thermal, or electrical properties.

How Vacuum Provides the Solution

By pumping the chamber down to a low-pressure state, a vacuum furnace creates an inert environment. This lack of atmosphere prevents the oxidation and contamination that would otherwise occur, ensuring the material particles can bond cleanly and efficiently.

How a Vacuum Sintering Furnace Works

The operation combines three key principles: material consolidation, atmospheric control, and targeted heating.

The Sintering Process Explained

Sintering starts with a "green part," which is powdered material (like metal or ceramic) that has been compacted into a desired shape. This part is porous and mechanically weak.

When heated inside the furnace to a temperature below its melting point, atomic diffusion causes the individual particles to fuse together, eliminating the pores and shrinking the part into a dense, solid mass.

Creating the Vacuum

Before heating, a powerful system of vacuum pumps evacuates the sealed furnace chamber. This removes the vast majority of air and other gases, creating the necessary low-pressure environment for a clean sintering process.

The Role of Heating

Once the vacuum is established, heating elements inside the furnace raise the temperature. Heat transfer occurs primarily through thermal radiation and conduction, as there is no air to facilitate convection.

Common methods include resistance heating or medium-frequency induction heating, which is particularly effective for conductive metals.

The Result: Dense, High-Performance Materials

The combination of high heat and a clean vacuum environment allows the particles to bond without interference. The final product is a fully dense component with exceptional purity, strength, and performance characteristics that are often impossible to achieve with conventional atmospheric furnaces.

Understanding the Trade-offs

While powerful, vacuum sintering is not a universal solution. It involves specific constraints and considerations.

Cost and Complexity

Vacuum sintering furnaces are complex, high-precision machines. They represent a significant capital investment and require skilled operators for programming, maintenance, and diagnostics.

Slower Cycle Times

Achieving a deep vacuum takes time. Furthermore, cooling the product is slower because convective cooling (transferring heat via air or gas) is not an option. This can lead to longer overall production cycles compared to atmospheric processes.

High Vapor Pressure Materials

Under a vacuum, some elements with high vapor pressure can essentially "boil off" or sublimate from the material being processed at high temperatures. This phenomenon must be carefully managed to prevent altering the material's composition.

Making the Right Choice for Your Goal

Deciding whether to use vacuum sintering depends entirely on the material requirements and the desired outcome.

- If your primary focus is achieving maximum material purity and density: Vacuum sintering is the essential choice to eliminate atmospheric contamination and achieve a fully dense structure.

- If you are working with reactive or refractory metals (like tungsten, titanium, or molybdenum): A vacuum environment is non-negotiable to prevent catastrophic oxidation at high processing temperatures.

- If cost and production speed are your main drivers for non-reactive materials: You may want to evaluate simpler and faster atmospheric furnaces or those using a protective gas atmosphere.

Ultimately, choosing vacuum sintering is a decision to prioritize final material integrity over process simplicity.

Summary Table:

| Aspect | Details |

|---|---|

| Primary Purpose | Fuse compacted powders into dense solids in a vacuum to prevent oxidation and contamination. |

| Key Benefits | Superior purity, high strength, elimination of defects, and enhanced material performance. |

| Ideal For | Reactive metals (e.g., titanium, tungsten), ceramics, and applications requiring high-density components. |

| Process Steps | Evacuate air, heat below melting point, bond particles via atomic diffusion, cool slowly. |

| Common Challenges | Higher cost, slower cycle times, risk of vapor loss for high vapor pressure materials. |

Ready to elevate your material processing with high-purity results? KINTEK specializes in advanced high-temperature furnace solutions, including Vacuum Sintering Furnaces, designed to eliminate contamination and deliver superior strength and density for your metals and ceramics. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs. Contact us today to discuss how our expertise can optimize your sintering processes and achieve your goals!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What is the sintering process in dentistry? Unlock the Strength of Zirconia Restorations