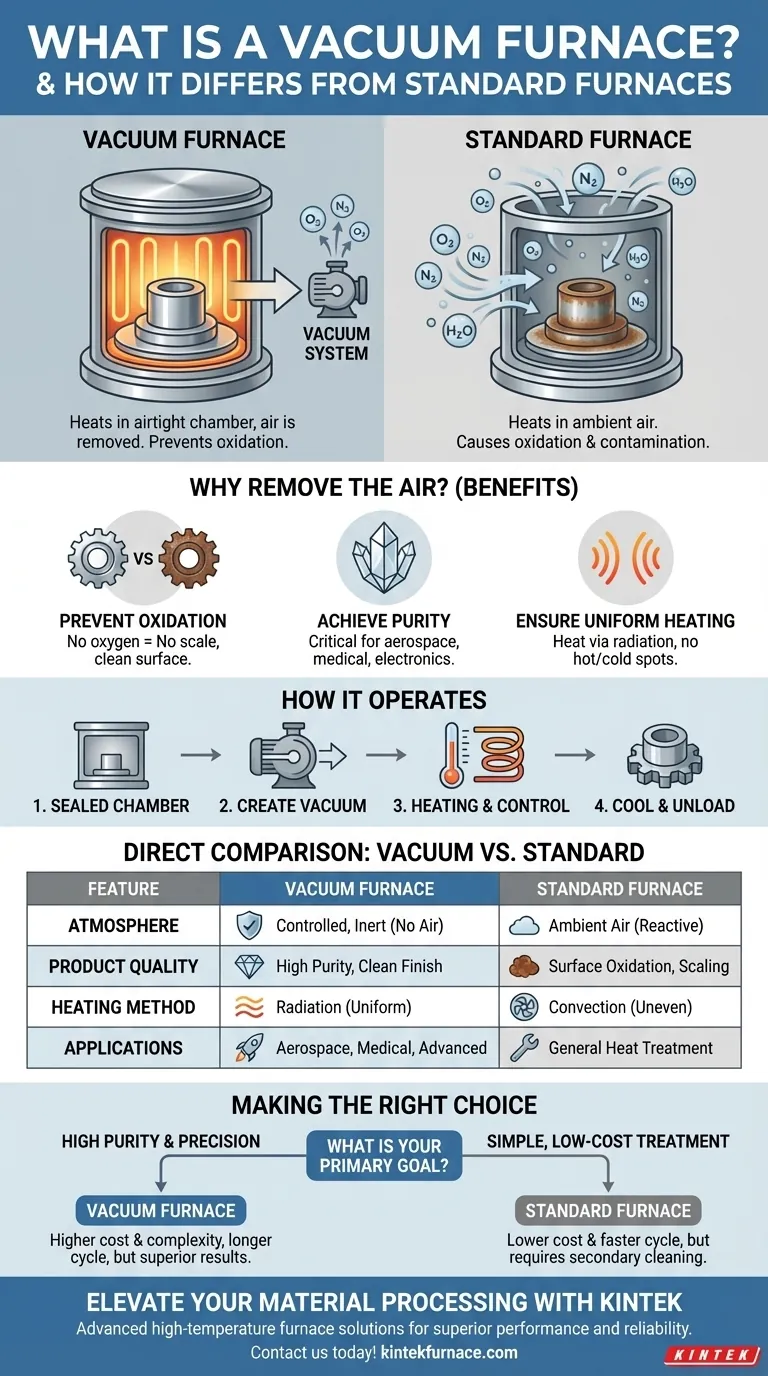

At its core, a vacuum furnace is a specialized furnace that heats materials inside a chamber from which the air has been removed. Unlike standard furnaces that heat materials in the presence of ambient air, a vacuum furnace creates an airtight, controlled environment. This single difference—the removal of air and oxygen—is what allows it to prevent unwanted chemical reactions like oxidation, resulting in a fundamentally higher-quality and purer end product.

The critical distinction is not about generating heat, but about controlling the environment. A standard furnace only controls temperature, while a vacuum furnace controls both temperature and the atmosphere, protecting the material from the reactive elements in the air.

The Fundamental Principle: Why Remove the Air?

The decision to use a vacuum furnace is driven by the need to protect the material being heated. At high temperatures, the oxygen and other gases present in normal air become highly reactive, fundamentally altering the material's properties.

Preventing Oxidation and Contamination

When metals and other materials are heated to high temperatures in air, they react with oxygen. This process, oxidation, creates a layer of scale or discoloration on the surface, which can compromise the part's integrity and finish.

By using a vacuum pump to remove nearly all the air from the sealed chamber, a vacuum furnace eliminates the oxygen. This prevents oxidation and other forms of atmospheric contamination from ever occurring.

Achieving Material Purity and Integrity

The result of preventing these reactions is a clean, bright, and high-purity end product. The material retains its desired surface finish and metallurgical properties without any degradation.

This is critical in high-performance industries like aerospace, medical, and electronics, where even minor impurities or surface flaws can lead to component failure.

Ensuring Uniform Heating

In a standard furnace, heat is transferred through convection (air currents), which can create hot and cold spots. In a vacuum, heat is transferred primarily through radiation.

This allows for more uniform, consistent, and precisely controlled heating of the entire part, reducing internal stresses and the risk of warping.

How a Vacuum Furnace Operates

A vacuum furnace is a more complex system than a standard furnace, incorporating several key components to manage the environment.

The Vacuum System

The process begins by placing the material inside a sealed chamber, typically constructed from stainless steel to ensure integrity. A powerful pumping system then removes the air and other gases to achieve the desired level of vacuum.

The quality of the seals and the chamber's construction, often featuring dual-wall, water-cooled designs, are critical for maintaining this vacuum throughout the heating cycle.

The Heating and Control System

Once the vacuum is established, internal heating elements raise the temperature. These can be standard resistance elements or, in some specialized models like a vacuum induction furnace, an induction coil that heats the material directly.

A sophisticated temperature control system precisely regulates the heating and cooling rates, ensuring the material undergoes the exact treatment required.

Key Differences from Standard Furnaces: A Direct Comparison

While both types of furnaces heat materials, their applications and results are vastly different.

Atmosphere and Environment

A standard furnace operates in ambient air. A vacuum furnace operates in a controlled, inert environment devoid of reactive gases. Some variants, like a retort furnace, may use this vacuum capability to first remove the air and then backfill the chamber with a specific, controlled gas.

End Product Quality

Processing in a standard furnace often results in surface oxidation, requiring secondary cleaning processes like sandblasting or chemical baths. A vacuum furnace produces a clean, finished part directly from the furnace, with no scaling.

Process Control and Repeatability

Vacuum furnaces offer far superior control over the heating process and atmospheric conditions. This leads to highly repeatable, consistent results that are essential for certified and mission-critical applications.

Understanding the Trade-offs

The superior results of a vacuum furnace come with specific considerations.

Cost and Complexity

Vacuum furnaces are significantly more complex and expensive than standard atmospheric furnaces. The need for a robust vacuum chamber, pumps, and advanced control systems increases both the initial investment and maintenance costs.

Cycle Time

Achieving a deep vacuum before the heating cycle begins, and often cooling the part under vacuum or inert gas, can extend the total process time compared to a simple atmospheric heat treatment.

Sample and Size Constraints

The design of the furnace can limit the size of the components being processed. Vacuum tube furnaces, for example, are excellent for high-precision treatment of small parts but are unsuitable for bulky items. A larger vacuum muffle furnace is required for bigger loads.

Making the Right Choice for Your Goal

Selecting the right furnace depends entirely on the requirements of your material and the desired outcome.

- If your primary focus is simple, low-cost heat treatment where surface finish is not critical: A standard atmospheric furnace is the most economical choice.

- If your primary focus is achieving the highest material purity and preventing any oxidation: A vacuum furnace is essential for applications in aerospace, medical, or advanced manufacturing.

- If your primary focus is treating small, uniform parts with maximum precision: A vacuum tube furnace offers excellent control in a compact form factor.

- If your primary focus is processing large components or bulk loads without contamination: A vacuum muffle furnace provides the necessary capacity while protecting the material.

Ultimately, choosing a vacuum furnace is an investment in process control to guarantee the final integrity of your material.

Summary Table:

| Feature | Vacuum Furnace | Standard Furnace |

|---|---|---|

| Atmosphere | Controlled vacuum or inert gas | Ambient air |

| Oxidation Prevention | Yes, eliminates oxygen | No, oxidation occurs |

| End Product Quality | High purity, no scaling | Surface oxidation, requires cleaning |

| Heating Method | Radiation for uniform heating | Convection with potential hot spots |

| Cost and Complexity | Higher initial and maintenance costs | Lower cost and simpler design |

| Ideal Applications | Aerospace, medical, electronics | General heat treatment where finish isn't critical |

Ready to elevate your material processing with precision and purity? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all supported by strong deep customization capabilities to meet your unique experimental requirements. Whether you're in aerospace, medical, or electronics, we ensure superior performance and reliability. Contact us today to discuss how our furnaces can enhance your lab's efficiency and deliver flawless results!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why should nitrogen not be used as a cooling gas for titanium alloys in vacuum heat treatment? Avoid Catastrophic Failures

- How does a vacuum heat treatment furnace prevent contamination? Ensure Purity in High-Temperature Processes

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control