In short, future advancements in vacuum and protective atmosphere melting are focused on making the process more intelligent, efficient, and precise. The primary driver for this evolution is not just in furnace design, but in the underlying power electronics—such as next-generation IGBTs—and the integration of advanced digital process control, which together enable unprecedented levels of material purity and performance.

The next frontier for high-purity melting technology is not simply about achieving a better vacuum. It is about transforming the melting process itself from a craft into a data-driven science, using superior power control and real-time analytics to achieve flawless material consistency.

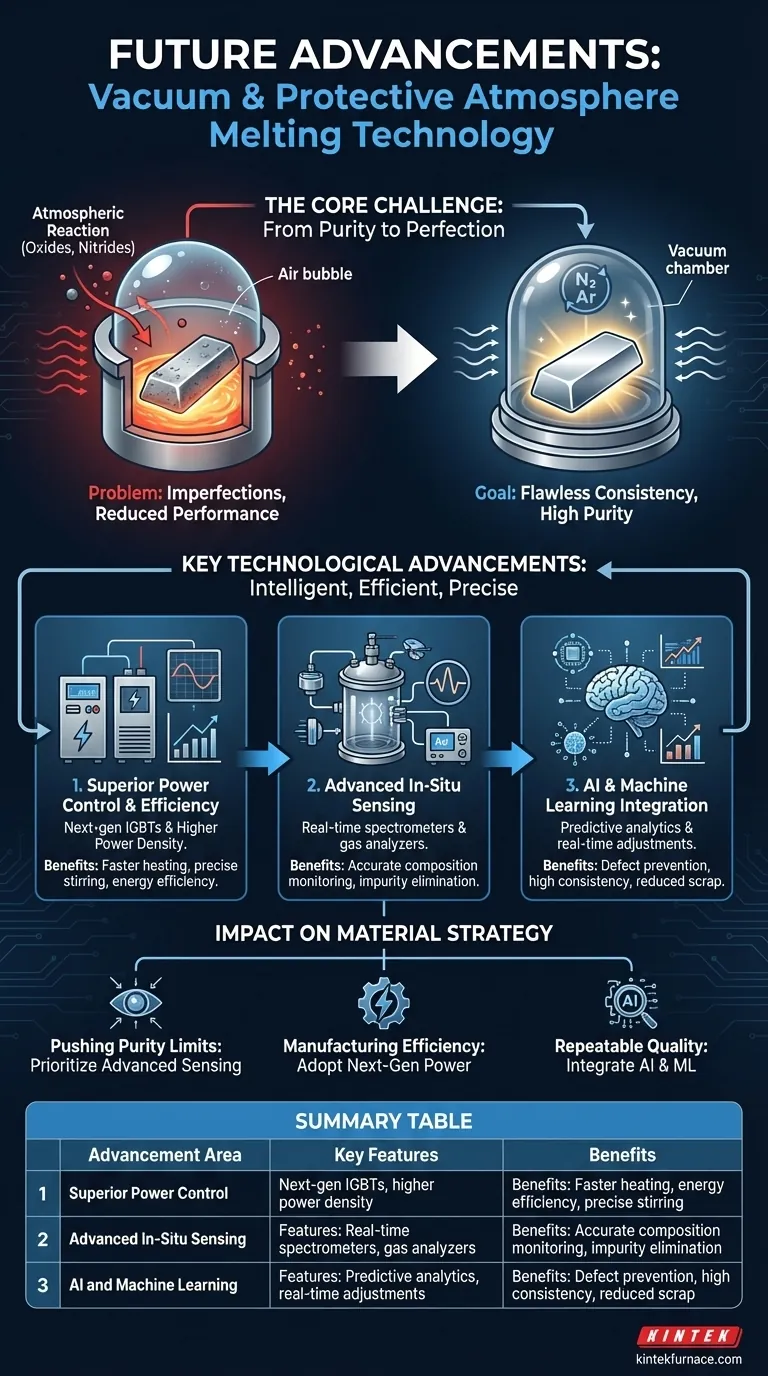

The Core Challenge: From Purity to Perfection

High-performance industries depend on materials that are free from impurities and structural defects. The entire purpose of melting in a vacuum or a controlled, inert atmosphere is to protect highly reactive or sensitive metals from contamination by oxygen, nitrogen, and other atmospheric elements.

The Problem of Atmospheric Reaction

When metals like titanium, nickel-based superalloys, or high-purity copper are melted in open air, they react with the atmosphere. This introduces oxides and nitrides, which create imperfections in the final material, drastically reducing its strength, conductivity, and corrosion resistance.

The Goal of Flawless Consistency

For critical components like aerospace turbine blades or medical implants, even microscopic inconsistencies can lead to catastrophic failure. The goal of advanced melting technology is to produce alloys that are perfectly homogeneous and free of defects, not just once, but every single time.

Key Areas of Technological Advancement

Future progress is centered on a feedback loop of better control, better sensing, and smarter analysis. These elements work together to elevate the precision of the entire melting process.

Superior Power Control and Efficiency

The most significant near-term advancements are happening in the power supply. Modern induction melting relies on Insulated-Gate Bipolar Transistors (IGBTs) to generate the powerful magnetic fields that heat and stir the metal.

Future IGBTs will offer higher power density and more sophisticated control. This allows for faster, more uniform heating and precise temperature management, reducing energy waste and shortening cycle times. Enhanced control also means the electromagnetic stirring of the molten metal can be fine-tuned to ensure a perfectly mixed, homogeneous alloy.

Advanced In-Situ Sensing

You cannot control what you cannot measure. The next generation of vacuum furnaces will incorporate a suite of advanced, real-time sensors directly within the melt chamber.

These systems will go beyond simple temperature and pressure readings. Expect to see integrated optical emission spectrometers to monitor the exact chemical composition of the melt in real time, and advanced gas analyzers to ensure the absolute purity of the protective atmosphere.

Integration of AI and Machine Learning

With massive amounts of data coming from advanced sensors, the next logical step is using Artificial Intelligence (AI) to interpret it. Machine learning models can be trained to recognize subtle patterns in the melt process that precede the formation of a defect.

Instead of relying solely on an operator's experience, an AI-driven system could automatically adjust power, pressure, or gas flow in real-time to prevent issues before they occur. This leads to higher yields, less scrap, and unparalleled batch-to-batch consistency.

Understanding the Trade-offs

While these advancements promise significant benefits, they also introduce new complexities that must be carefully managed.

The Challenge of System Integration

Integrating new sensors, AI algorithms, and advanced power supplies into a cohesive system is a complex engineering task. It requires deep expertise in materials science, electronics, and software engineering to ensure all components work together reliably and provide accurate data.

The High Cost of Cutting-Edge Technology

State-of-the-art furnaces equipped with these technologies represent a significant capital investment. The decision to upgrade must be weighed against the tangible benefits of improved material quality, reduced energy consumption, and higher production yields.

The Demand for New Skills

As melting systems become more sophisticated, the role of the operator evolves. Running an AI-assisted furnace requires skills in data interpretation and system management, not just traditional metallurgical expertise. Companies will need to invest in training to leverage the full potential of these technologies.

How This Impacts Your Material Strategy

Your approach to adopting these technologies should align directly with your primary objective.

- If your primary focus is pushing the limits of material purity: Prioritize investments in advanced in-situ sensing and atmosphere control to eliminate even trace contaminants.

- If your primary focus is manufacturing efficiency and cost reduction: The adoption of next-generation IGBT power supplies will provide the most immediate return through faster cycles and lower energy usage.

- If your primary focus is repeatable quality for critical components: The integration of AI and machine learning offers the ultimate path to predictive quality control and minimizing batch-to-batch variation.

Ultimately, these advancements are moving vacuum and protective atmosphere melting from a heavily controlled process to an intelligently optimized one.

Summary Table:

| Advancement Area | Key Features | Benefits |

|---|---|---|

| Superior Power Control | Next-gen IGBTs, higher power density | Faster heating, energy efficiency, precise stirring |

| Advanced In-Situ Sensing | Real-time spectrometers, gas analyzers | Accurate composition monitoring, impurity elimination |

| AI and Machine Learning | Predictive analytics, real-time adjustments | Defect prevention, high consistency, reduced scrap |

Ready to elevate your material processing with cutting-edge vacuum melting solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're focused on material purity, manufacturing efficiency, or repeatable quality, our technologies can help you achieve flawless results. Contact us today to discuss how we can support your laboratory's goals!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys

- What are the advantages of vacuum induction melting? Achieve Superior Purity for High-Performance Alloys

- What are the key components of a Vacuum Induction Melting (VIM) furnace? Master High-Purity Metal Processing

- What industries benefit from Vacuum Induction Melting Furnaces? Unlock High-Purity Metals for Aerospace, Medical, and More

- What are the main industrial applications of vacuum melting furnaces? Achieve Unmatched Material Purity and Performance