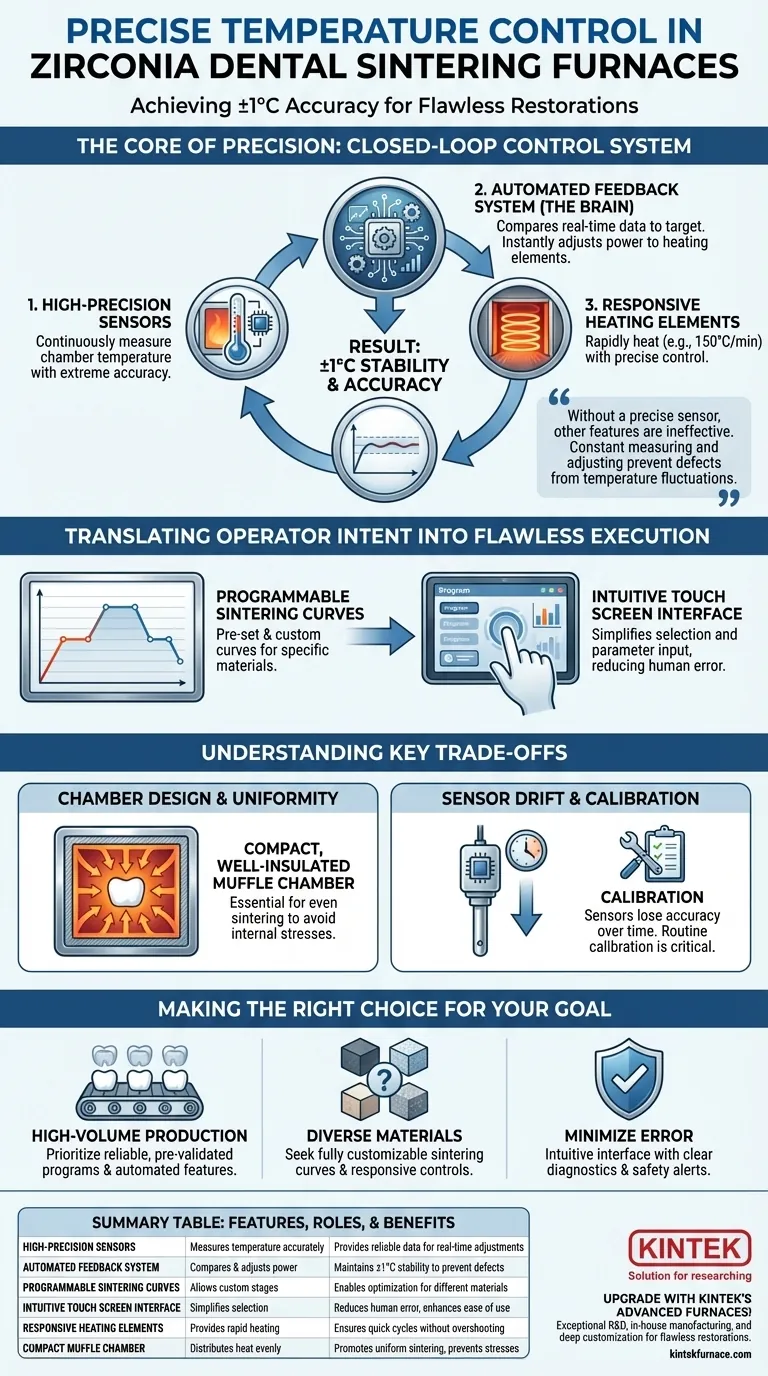

Precise temperature control in a Zirconia Dental Sintering Furnace is primarily achieved through a combination of high-precision sensors, an automated feedback system, and highly programmable heating cycles. This synergy ensures the furnace can not only reach a specific temperature but also follow a complex, time-based profile with an accuracy of ±1°C, which is critical for producing flawless dental restorations.

The core challenge isn't just hitting a target temperature; it's about flawlessly executing a pre-defined temperature profile over time. A furnace's precision comes from a closed-loop system that constantly measures, compares, and corrects to guarantee the final restoration's structural integrity.

The Core of Precision: The Closed-Loop Control System

The foundation of accurate sintering is a system that can sense and react in real-time. This is known as a closed-loop control system, and it consists of several key components working in unison.

High-Precision Sensors

The sensors act as the furnace's internal thermometer. They continuously measure the temperature inside the chamber with extreme accuracy.

Without a precise and reliable sensor, any other feature is rendered ineffective. It provides the raw data the system needs to make intelligent decisions.

The Automatic Feedback System

This system is the "brain" of the furnace. It takes the real-time temperature data from the sensors and compares it to the target temperature set by the sintering program.

If there is any deviation, the feedback system instantly adjusts the power output to the heating elements, either increasing or decreasing it to bring the chamber back to the exact target temperature.

The Result: ±1°C Accuracy

The constant cycle of measuring and adjusting by the feedback system is what allows the furnace to maintain a temperature stability of ±1°C.

This level of accuracy is not just a specification; it is a requirement. It prevents the material defects that can arise from even minor temperature fluctuations during the critical sintering process.

Translating Operator Intent into Flawless Execution

A robust control system is only half the equation. The furnace must also provide the operator with the tools to define the exact process needed for different materials and outcomes.

Programmable Sintering Curves

Zirconia and other dental ceramics do not sinter at a single temperature. They require a specific "curve"—a series of heating, holding, and cooling stages.

Modern furnaces feature multiple preset and customizable programs. This allows a technician to select a validated program for a common material or create a unique curve for a specialized case, ensuring optimal material properties.

Intuitive Touch Screen Interface

An intuitive touch screen interface is the bridge between the operator and the machine's complex internal processes.

It simplifies the selection of presets or the input of custom parameters, reducing the risk of human error that could compromise a cycle.

Responsive Heating Elements

The ability to heat rapidly, such as at a rate of 150°C per minute, demonstrates the power of the heating elements.

However, this speed must be managed by the control system to prevent "overshooting" the target temperature. Precise control is what makes this rapid heating usable and safe for the material.

Understanding the Key Trade-offs

While these features define a high-quality furnace, their implementation involves trade-offs and requires an understanding of the entire system.

The Importance of Chamber Design

A precise temperature reading is only useful if the temperature is uniform throughout the entire chamber. A compact, well-insulated muffle chamber is designed to distribute heat evenly.

Without uniform heat, parts of a dental bridge could be perfectly sintered while other parts are under-sintered, creating internal stresses and potential points of failure.

Pre-set vs. Custom Programs

Pre-set programs offer safety and repeatability, as they have been validated by the manufacturer. This is ideal for high-volume labs focused on consistency.

Custom programming, while powerful, introduces the risk of error. It requires deep material knowledge to create a cycle that optimizes results without causing defects.

The Risk of Sensor Drift

Over time and with repeated high-temperature cycles, even high-precision sensors can lose their initial accuracy. This phenomenon is known as sensor drift.

This is why routine maintenance and calibration are critical. Trusting an uncalibrated furnace is a significant risk, as the displayed temperature may no longer reflect the true internal temperature.

Making the Right Choice for Your Goal

The ideal furnace depends entirely on the specific needs of your dental lab or practice.

- If your primary focus is high-volume, standardized production: Prioritize furnaces with reliable, pre-validated programs and automated features like tray handling.

- If your primary focus is working with diverse or new materials: Seek a furnace with fully customizable sintering curves and a highly responsive control system.

- If your primary focus is minimizing operational error: An intuitive touch screen with clear diagnostics and safety alerts is a non-negotiable feature.

Ultimately, investing in a furnace with superior temperature control is an investment in the consistent quality and structural integrity of every restoration you produce.

Summary Table:

| Feature | Role in Temperature Control | Key Benefit |

|---|---|---|

| High-Precision Sensors | Measures temperature with extreme accuracy | Provides reliable data for real-time adjustments |

| Automated Feedback System | Compares actual vs. target temperature and adjusts power | Maintains ±1°C stability to prevent defects |

| Programmable Sintering Curves | Allows custom heating, holding, and cooling stages | Enables optimization for different materials and outcomes |

| Intuitive Touch Screen Interface | Simplifies program selection and parameter input | Reduces human error and enhances ease of use |

| Responsive Heating Elements | Provides rapid heating (e.g., 150°C per minute) | Ensures quick cycle times without overshooting |

| Compact Muffle Chamber | Distributes heat evenly throughout the chamber | Promotes uniform sintering and prevents internal stresses |

Upgrade your dental lab with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide precise solutions like Muffle, Tube, and Vacuum Furnaces tailored for dental sintering. Our strong deep customization capability ensures your unique experimental needs are met, delivering flawless restorations and enhanced productivity. Contact us today to discuss how our products can benefit your practice!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What are the effects of overloading a dental sintering furnace? Ensure Predictable, High-Quality Zirconia Restorations

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations