In short, Silicon Carbide (SiC) heating elements offer significant design advantages centered on their ability to operate at extremely high temperatures, their exceptional durability, and their rapid heating efficiency. These properties allow for more robust, reliable, and cost-effective designs in demanding industrial applications compared to traditional metallic elements, which falter under similar conditions.

The primary advantage of SiC is not merely its high-temperature capability, but its fundamental material stability. This stability translates directly into longer life, faster processing, and greater design freedom, making it the superior choice for applications where reliability and efficiency are non-negotiable.

Unlocking High-Temperature Operations

The most recognized benefit of SiC is its ability to perform in environments where conventional elements would fail. This capability is rooted in its unique material properties.

Exceeding the Limits of Metallic Elements

Silicon carbide can operate at furnace temperatures far higher than even the best metallic alloys like Kanthal (FeCrAl) or Nichrome (NiCr). This opens up processes that are simply not feasible with metal heaters.

Ensuring Thermal Uniformity

SiC possesses excellent thermal conductivity. This ensures heat is transferred efficiently and evenly throughout a furnace or kiln, which is critical for process quality in applications like semiconductor manufacturing, glass processing, and metal heat treating.

Resisting Thermal Shock

A low coefficient of thermal expansion means SiC elements do not expand or contract drastically with temperature changes. This, combined with their high mechanical strength, makes them highly resistant to thermal shock—the stress that causes cracking during rapid heating or cooling cycles.

Designing for Longevity and Reduced Downtime

An element's operational lifespan is a critical design factor, directly impacting maintenance schedules, downtime, and total cost of ownership. SiC is engineered for durability.

Superior Oxidation and Chemical Resistance

At high temperatures, elements are under constant attack from atmospheric oxygen and process chemicals. SiC naturally forms a protective, non-conductive layer of silicon dioxide (SiO₂) on its surface, which inhibits further oxidation and corrosion, dramatically extending its service life.

High Mechanical Strength

Unlike metallic elements that can sag, stretch, or become brittle over time at high temperatures (a phenomenon known as "creep"), SiC maintains its rigidity and shape. This structural integrity reduces the need for complex support structures and minimizes the risk of element failure and contact with the product.

Inherent Safety Properties

As a ceramic material, SiC is an excellent electrical insulator at room temperature and possesses non-flammable properties. This inherently reduces the risk of electrical shorts and fire hazards, contributing to a safer operational environment.

Understanding the Trade-offs

No material is without its considerations. An objective analysis requires understanding the full picture.

Higher Initial Investment

SiC heating elements typically have a higher upfront cost compared to their metallic counterparts. The decision to use SiC is therefore an evaluation of total cost of ownership, weighing the initial price against longer life, reduced energy use, and less downtime.

Brittleness Compared to Metals

While mechanically strong, SiC is a ceramic and is therefore brittle. It can fracture from sharp mechanical impacts during shipping, installation, or maintenance. This necessitates more careful handling procedures than with ductile metallic elements.

Resistance Increase Over Time (Aging)

As SiC elements operate, their electrical resistance gradually increases. This "aging" process is a normal characteristic. However, it requires a power control system (typically using SCRs) capable of adjusting the voltage to maintain consistent power output, adding a layer of complexity to the control system design.

Making the Right Choice for Your Application

Your choice of heating element should be driven by the specific demands of your process.

- If your primary focus is maximum temperature and process speed: SiC is the definitive choice for applications operating above 1250°C (2280°F) or those requiring very rapid heating cycles.

- If your primary focus is reliability in harsh environments: SiC's resistance to oxidation and chemical attack makes it ideal for furnaces with aggressive atmospheres or frequent thermal cycling.

- If your primary focus is minimizing initial capital cost: For lower-temperature applications (below 1200°C) without harsh chemicals, traditional metallic elements may remain a more cost-effective initial choice.

Ultimately, selecting SiC is an investment in operational stability, long-term performance, and higher process efficiency.

Summary Table:

| Advantage | Description |

|---|---|

| High-Temperature Operation | Exceeds limits of metallic elements, ideal for processes above 1250°C |

| Thermal Uniformity | Excellent conductivity ensures even heat distribution |

| Thermal Shock Resistance | Low expansion and high strength prevent cracking |

| Longevity | Oxidation and chemical resistance extend service life |

| Mechanical Strength | Maintains shape, reducing sag and failure risks |

| Safety | Electrical insulation and non-flammable properties |

| Considerations | Higher initial cost, brittleness, resistance aging |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide SiC heating elements and custom furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization ensures precise fit for your unique experimental needs, enhancing efficiency and reliability. Contact us today to discuss how we can optimize your processes!

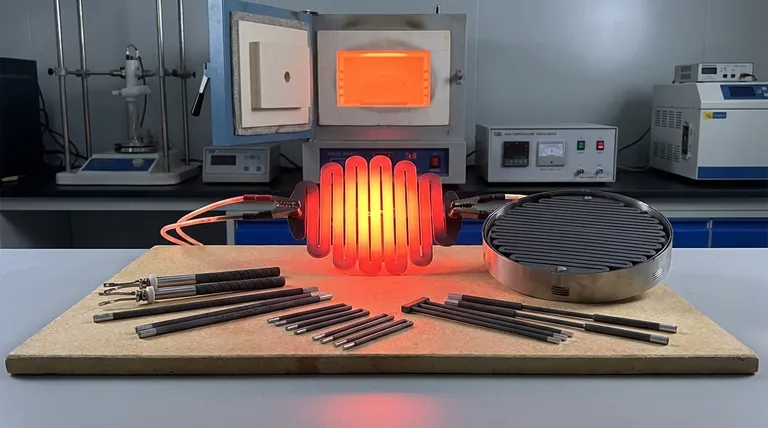

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability