Spalling in MoSi2 heating elements is a form of surface degradation caused by operating them in a reducing atmosphere. This environment prevents the element from forming a new, protective silicon dioxide (SiO2) layer, leading to the existing layer flaking off. It can be addressed by periodically firing the elements in an oxidizing atmosphere to regenerate this layer or by selecting elements with a thicker protective coating from the outset.

Spalling is not just cosmetic damage; it is a sign that the element's fundamental self-healing mechanism has been compromised. The key to long-term reliability is managing the furnace atmosphere to ensure this protective layer can be maintained or reformed.

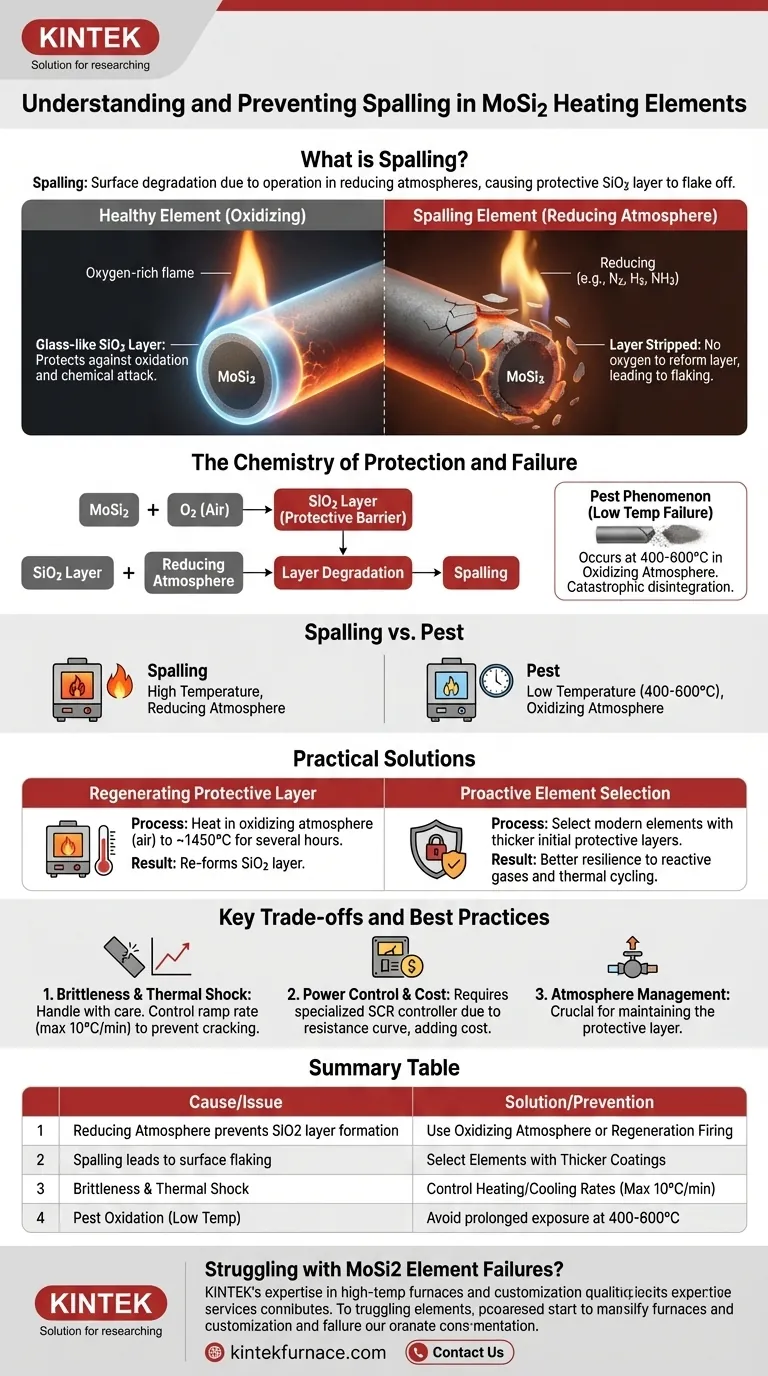

The Chemistry of Protection and Failure

To understand spalling, you first must understand how a healthy MoSi2 element works. The material's remarkable high-temperature performance relies on a delicate chemical balance with its environment.

The Self-Healing SiO2 Layer

Molybdenum disilicide (MoSi2) is a ceramic-metallic composite. When heated in the presence of oxygen (like in air), it forms a thin, non-porous layer of pure silicon dioxide (SiO2) on its surface.

This glass-like SiO2 layer is the key to the element's longevity. It acts as a robust barrier, protecting the underlying MoSi2 material from further oxidation and chemical attack at extreme temperatures.

How Reducing Atmospheres Cause Spalling

A reducing atmosphere is an environment that lacks sufficient free oxygen. Common examples include nitrogen, hydrogen, or cracked ammonia.

In these conditions, the protective SiO2 layer can be chemically stripped away. Crucially, without available oxygen, the element cannot "heal" itself by forming a new layer. The exposed surface then becomes unstable, leading to the degradation and flaking known as spalling.

The Pest Phenomenon: A Related Failure

It is critical to distinguish spalling from another failure mode called "pest" oxidation. This is a catastrophic disintegration of the element into powder that occurs at low temperatures, typically between 400°C and 600°C.

While spalling is a high-temperature issue in reducing atmospheres, pesting is a low-temperature failure in oxidizing atmospheres. Both underscore the absolute importance of temperature and atmosphere control.

Practical Solutions for Element Degradation

Addressing element degradation involves both reactive and proactive measures. You can either repair the damage after it occurs or choose a more robust element from the start.

Regenerating the Protective Layer

If elements show signs of spalling after use in a reducing atmosphere, their protective layer can often be reformed.

This is done through a regeneration firing. The process involves heating the elements in an oxidizing atmosphere (air) to a high temperature, often around 1450°C, and holding them for several hours. This provides the necessary heat and oxygen to "re-glass" the surface and restore the SiO2 layer.

Proactive Prevention Through Element Selection

A more durable solution is to select an element designed for your specific application. Modern MoSi2 elements are available with thicker initial protective layers or specialized compositions.

These advanced elements are more resilient to intermittent exposure to reducing atmospheres and are better suited for challenging processes involving reactive gases or rapid thermal cycling.

Understanding the Trade-offs of MoSi2

MoSi2 elements offer exceptional temperature capability, but their use involves significant trade-offs that every operator must understand to prevent failure.

Inherent Brittleness and Thermal Shock

As a ceramic material, MoSi2 is extremely brittle at room temperature. The elements must be handled with great care during installation and maintenance to avoid fracture.

They are also susceptible to thermal shock. Rapid heating or cooling can create internal stresses that lead to cracking. A controlled ramp rate, often limited to a maximum of 10°C per minute, is essential to prevent this type of mechanical failure.

Power Control and Cost

MoSi2 elements have a unique electrical resistance curve. They have very low resistance at room temperature, which increases dramatically as they heat up.

This characteristic requires a specialized power controller, typically an SCR paired with a step-down transformer, to manage the high initial start-up current. This equipment adds significant cost and complexity compared to systems for simple metallic elements.

How to Apply This to Your Project

Your strategy for element longevity depends entirely on your furnace's operating conditions and goals.

- If your primary focus is high-temperature operation in an oxidizing atmosphere: Standard MoSi2 elements are an excellent choice, but you must strictly control heating and cooling rates to prevent thermal shock.

- If your primary focus is processing in a reducing or reactive atmosphere: You must either plan for periodic regeneration cycles in air or invest in specialized, more costly elements designed for these conditions.

- If your primary focus is frequent cycling from room temperature: You must ensure the element passes through the low-temperature "pest" range (400-600°C) as quickly as your ramp rate limits allow.

Ultimately, understanding the interplay between atmosphere and temperature is the key to maximizing the life and performance of your MoSi2 heating elements.

Summary Table:

| Cause/Issue | Solution/Prevention |

|---|---|

| Reducing atmosphere prevents SiO2 layer formation | Use oxidizing atmosphere or periodic regeneration firing |

| Spalling leads to surface flaking | Select elements with thicker protective coatings |

| Brittleness and thermal shock risk | Control heating/cooling rates (max 10°C/min) |

| Pest oxidation at low temperatures | Avoid prolonged exposure in 400-600°C range |

Struggling with MoSi2 heating element failures in your lab? KINTEK specializes in advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Leveraging exceptional R&D and in-house manufacturing, we offer deep customization to precisely meet your unique experimental needs—whether you're dealing with spalling, thermal shock, or atmosphere control challenges. Contact us today to enhance your lab's efficiency and reliability with tailored solutions!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the operating temperature of SiC? Unlock Reliable Performance Up to 1600°C

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C