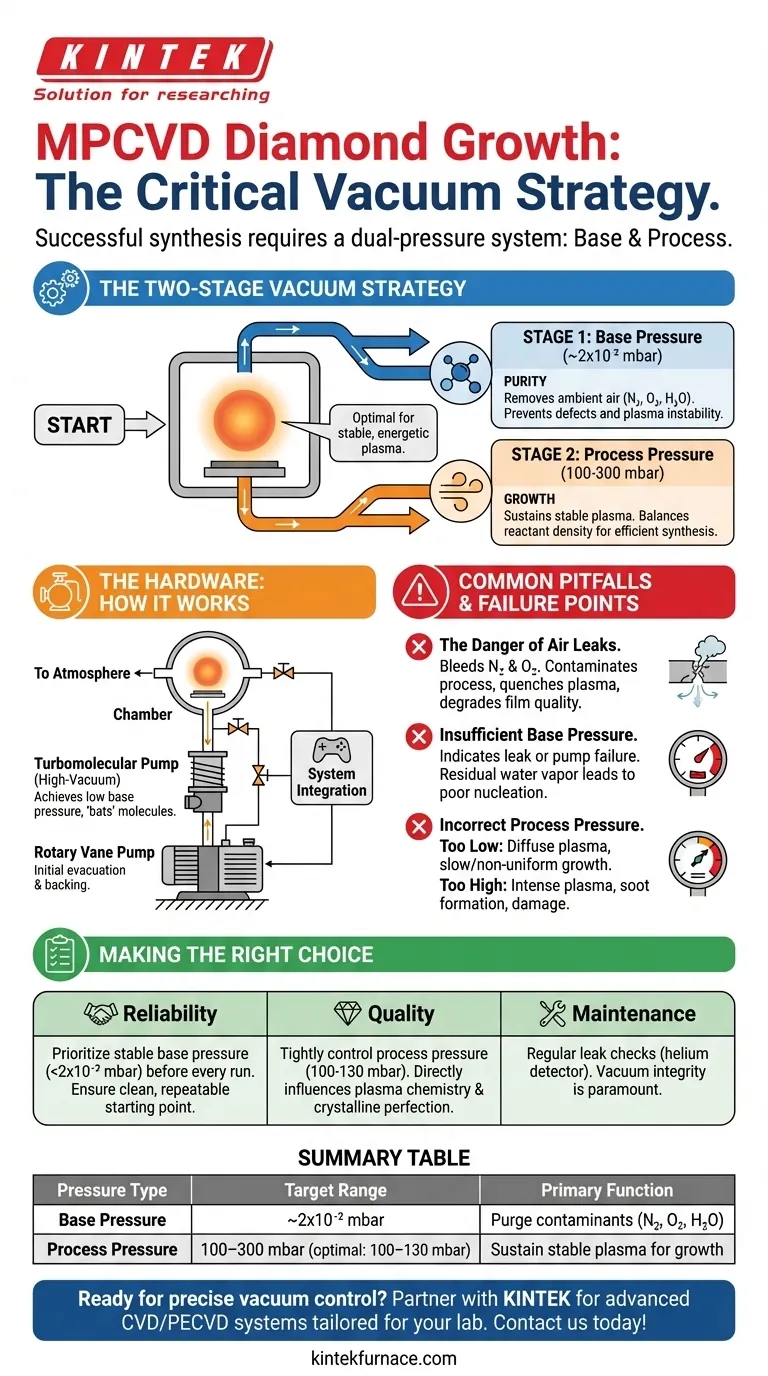

For successful MPCVD diamond growth, the vacuum system must meet two distinct pressure requirements. First, an initial base pressure of approximately 2x10⁻² mbar is required to purge the chamber of atmospheric contaminants. Second, a stable process pressure between 100 and 300 mbar (typically 100-130 mbar) must be maintained during growth to sustain the plasma.

The dual-pressure strategy is the core of MPCVD vacuum control. The initial low pressure ensures purity, while the subsequent higher pressure creates the optimal density for plasma chemistry, directly governing the quality and rate of diamond synthesis.

The Two-Stage Vacuum Strategy: Base vs. Process Pressure

An MPCVD system's vacuum protocol is not a single target but a two-step process. Each step serves a distinct and critical purpose for creating high-quality diamond film.

Establishing the Baseline: The Role of Base Pressure (~2x10⁻² mbar)

Before introducing any process gases like hydrogen or methane, the chamber must be evacuated to a low base pressure.

The goal of this initial pump-down is purity. It forcefully removes ambient air—primarily nitrogen, oxygen, and water vapor—from the chamber and gas lines.

Failing to remove these contaminants can lead to poor film quality, defects in the crystal lattice, and instability in the plasma once it is ignited.

Creating the Growth Environment: The Role of Process Pressure (100-300 mbar)

Once the chamber is purged, process gases are introduced, and the pressure is intentionally raised and held steady. This is the process pressure.

This higher pressure is necessary to achieve a sufficient density of gas molecules to form a stable, energetic plasma ball around the substrate.

The pressure range of 100-300 mbar represents a critical balance. It's high enough to generate the required concentration of reactive species for efficient growth but low enough to prevent undesirable effects like plasma instability or soot formation.

The Hardware: How the Vacuum is Achieved

Achieving this dual-pressure requirement necessitates a sophisticated pumping system, typically involving two types of pumps working in series.

The Roughing Pump: A Two-Stage Rotary Vane Pump

The workhorse of the system is a rotary vane pump, often called a "roughing" or "backing" pump.

Its job is to do the initial heavy lifting, evacuating the chamber from atmospheric pressure down to the rough vacuum range. It then continues to operate to "back" the high-vacuum pump.

The High-Vacuum Pump: A Turbomolecular Pump

To reach the low base pressure target (2x10⁻² mbar), a turbomolecular pump ("turbo pump") is required.

This pump uses rapidly spinning blades (e.g., 69,000 rpm) to "bat" individual gas molecules from the chamber towards the backing pump's inlet. It can achieve very high compression ratios for gases like nitrogen, effectively scrubbing the chamber of residual contaminants.

System Integration and Control

The entire system is connected with specific vacuum hardware (like KF40 ports) and managed by a dedicated controller. This ensures the pumps work in concert and allows for precise pressure regulation as process gases flow into the chamber.

Common Pitfalls and Failure Points

The vacuum system is fundamental to the process, and its failure is a primary cause of poor growth results. Regular checks are essential to prevent common issues.

The Danger of Air Leaks

Even a minuscule leak in a seal or fitting can constantly bleed nitrogen and oxygen into the chamber during growth. This contaminates the process, quenches the plasma, and introduces defects into the diamond film, severely degrading its quality.

Insufficient Base Pressure

If the system cannot reach the target base pressure, it indicates either a leak or a failing pump. The consequence is that contaminants like water vapor remain in the chamber, leading to poor nucleation and inconsistent growth.

Incorrect Process Pressure

Deviating from the optimal process pressure window has immediate consequences.

- Too Low: The plasma may become diffuse and unstable, leading to a very slow or non-uniform growth rate.

- Too High: The plasma may shrink or become too intense, increasing the risk of gas-phase nucleation (soot) and potentially damaging the substrate or diamond film.

Making the Right Choice for Your Goal

The vacuum parameters are not arbitrary; they are directly tied to the desired outcome of your synthesis process.

- If your primary focus is process reliability: Prioritize achieving a stable base pressure well below 2x10⁻² mbar before every run. This ensures a clean, repeatable starting point.

- If your primary focus is optimizing diamond quality: Tightly control the process pressure within the 100-130 mbar range, as this directly influences plasma chemistry and crystalline perfection.

- If your primary focus is system maintenance: Implement a schedule for regular leak checks using a helium leak detector or residual gas analyzer. Vacuum integrity is paramount.

Ultimately, precise and reliable vacuum control is the non-negotiable foundation upon which all high-quality MPCVD diamond synthesis is built.

Summary Table:

| Pressure Type | Target Range | Primary Function |

|---|---|---|

| Base Pressure | ~2x10⁻² mbar | Purge contaminants (N₂, O₂, H₂O) for purity |

| Process Pressure | 100–300 mbar (optimal: 100–130 mbar) | Sustain stable plasma for efficient diamond growth |

Ready to build a reliable MPCVD process with precise vacuum control? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for your lab. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is backed by deep customization capabilities to meet your unique experimental needs. Ensure flawless diamond growth with a system designed for stability and purity. Contact us today to discuss your MPCVD requirements!

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

People Also Ask

- What are the outstanding characteristics of diamond self-supporting films prepared by MPCVD? Unlock Unmatched Thermal, Electrical & Optical Performance

- What is the future outlook for MPCVD in diamond synthesis? Scaling High-Purity Diamond Production

- Why is MPCVD considered versatile and important in multiple industries? Unlock Diamond's Potential

- What is the significance of stable discharge plasma in MPCVD? The Key to High-Quality Diamond Synthesis

- How does the MPCVD deposition process work? Unlock Superior Diamond Film Quality

- Why has MPCVD become a promising method for diamond thin film deposition? Discover High-Purity, Scalable Solutions

- What are the three types of CVD methods for synthesizing single crystal diamond? Compare MPCVD, DC-PJ CVD, and HFCVD for Your Lab

- How does MPCVD achieve high growth rates for diamond synthesis? Unlock Rapid, High-Quality Diamond Growth