High-purity quartz capillaries are the standard solution for in-situ Synchrotron X-ray Diffraction (SXRD) because they effectively decouple the sample environment from the measurement data. Specifically, the 0.7 mm diameter format offers an optimal balance, allowing high-energy beams (e.g., 55 keV) to penetrate the sample while maintaining structural integrity at temperatures as high as 1000°C during dynamic thermal processes.

The definitive value of high-purity quartz lies in its ability to remain virtually "invisible" to X-rays while acting as a robust vessel for samples undergoing extreme non-isothermal heating, ensuring data integrity during real-time structural analysis.

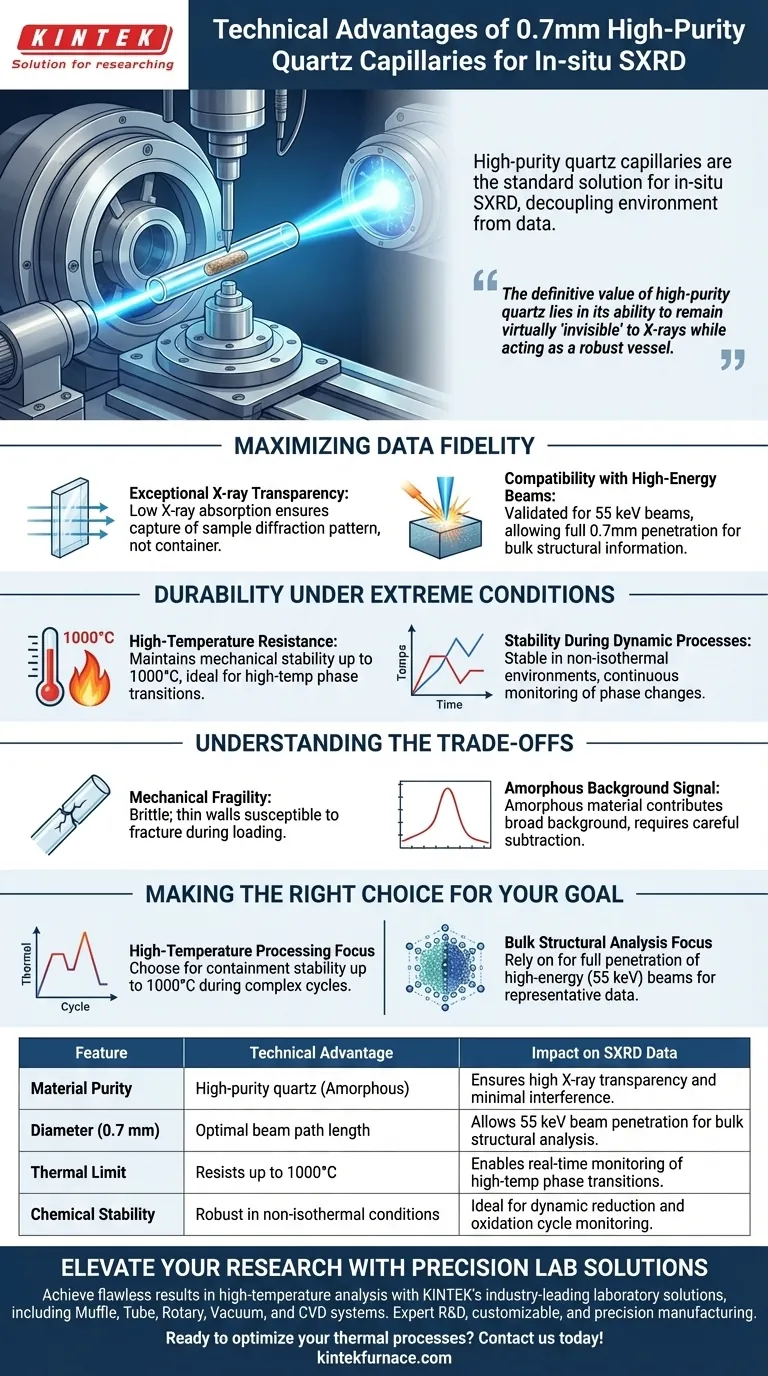

Maximizing Data Fidelity

To achieve accurate in-situ results, the containment material must not interfere with the diffraction signal.

Exceptional X-ray Transparency

The primary technical advantage of high-purity quartz is its low absorption of X-rays. This transparency is critical for ensuring that the detector captures the diffraction pattern of the sample material rather than the container.

Compatibility with High-Energy Beams

These capillaries are specifically validated for use with high-energy synchrotron radiation, such as 55 keV beams. This capability allows the beam to penetrate the entire 0.7 mm diameter of the sample, providing comprehensive bulk structural information rather than just surface data.

Durability Under Extreme Conditions

In-situ experiments are valuable because they replicate real-world processing environments, which often involve severe thermal stress.

High-Temperature Resistance

High-purity quartz capillaries are selected for their ability to withstand extreme heat. They maintain mechanical stability at temperatures up to 1000°C, making them ideal for studying high-temperature phase transitions.

Stability During Dynamic Processes

Beyond static heat resistance, these capillaries excel in non-isothermal environments. During reduction processes where temperatures fluctuate or ramp up, the quartz remains stable, allowing for the continuous dynamic monitoring of phase changes without failure.

Understanding the Trade-offs

While high-purity quartz is the superior choice for high-temperature SXRD, it is essential to recognize its limitations to ensure experimental success.

Mechanical Fragility

Despite their thermal robustness, quartz capillaries are mechanically brittle. The thin walls required for X-ray transparency make them susceptible to fracture during the sample loading and mounting process.

Amorphous Background Signal

While "transparent" to diffraction, quartz is an amorphous material. It can contribute a broad background signal (often called an "amorphous hump") to your data, which may require careful background subtraction during analysis to isolate weak sample peaks.

Making the Right Choice for Your Goal

The 0.7 mm high-purity quartz capillary is a precision tool designed for specific experimental parameters.

- If your primary focus is high-temperature processing: Choose this material to ensure containment stability up to 1000°C during complex reduction or oxidation cycles.

- If your primary focus is bulk structural analysis: Rely on these capillaries to permit full penetration of high-energy (55 keV) beams for representative volumetric data.

By leveraging the thermal stability and optical purity of these capillaries, you ensure that your experimental apparatus never compromises the fidelity of your observation.

Summary Table:

| Feature | Technical Advantage | Impact on SXRD Data |

|---|---|---|

| Material Purity | High-purity quartz (Amorphous) | Ensures high X-ray transparency and minimal interference. |

| Diameter (0.7 mm) | Optimal beam path length | Allows 55 keV beam penetration for bulk structural analysis. |

| Thermal Limit | Resists up to 1000°C | Enables real-time monitoring of high-temp phase transitions. |

| Chemical Stability | Robust in non-isothermal conditions | Ideal for dynamic reduction and oxidation cycle monitoring. |

Elevate Your Research with Precision Lab Solutions

To achieve flawless results in high-temperature analysis, you need equipment that withstands extreme conditions without compromising data integrity. KINTEK provides industry-leading laboratory solutions, including high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all designed to meet the rigorous demands of modern material science.

Backed by expert R&D and precision manufacturing, our high-temp furnaces are fully customizable to your unique experimental needs. Whether you are performing in-situ SXRD or complex material processing, KINTEK ensures your lab is equipped for success.

Ready to optimize your thermal processes? Contact us today to find the perfect solution for your lab!

Visual Guide

References

- Yuzhao Wang, Samuli Urpelainen. In Situ SXRD Study of Phase Transformations and Reduction Kinetics in Iron Ore During Hydrogen-Based High-Temperature Reduction. DOI: 10.1007/s11663-025-03725-2

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What roles do high-purity graphite molds play in SPS? Unlock the Secret to Superior Spark Plasma Sintering

- How does a heating stage contribute to the quality of multi-material 3D printing? Optimize Precision and Stability

- Why is a rotary evaporator used to process separated fractions in hydrotreated coal tar analysis? Enhance Sample Purity

- Why are alumina ceramic tubes preferred for high-temperature furnaces? Ensure Stability and Control Up to 1800°C

- What are the primary functions of a Quartz Flow Reactor? Enhance Precision in Oxidation Research

- What is the primary function of a constant temperature drying oven? Master S53P4 Bioactive Glass Gel Integrity

- Why are ceramic crucibles required for the high-temperature calcination of dolomite? Ensure High-Purity Results

- What is the importance of high-purity Argon flow control equipment? Ensure Purity in Pulsed Irradiation Synthesis