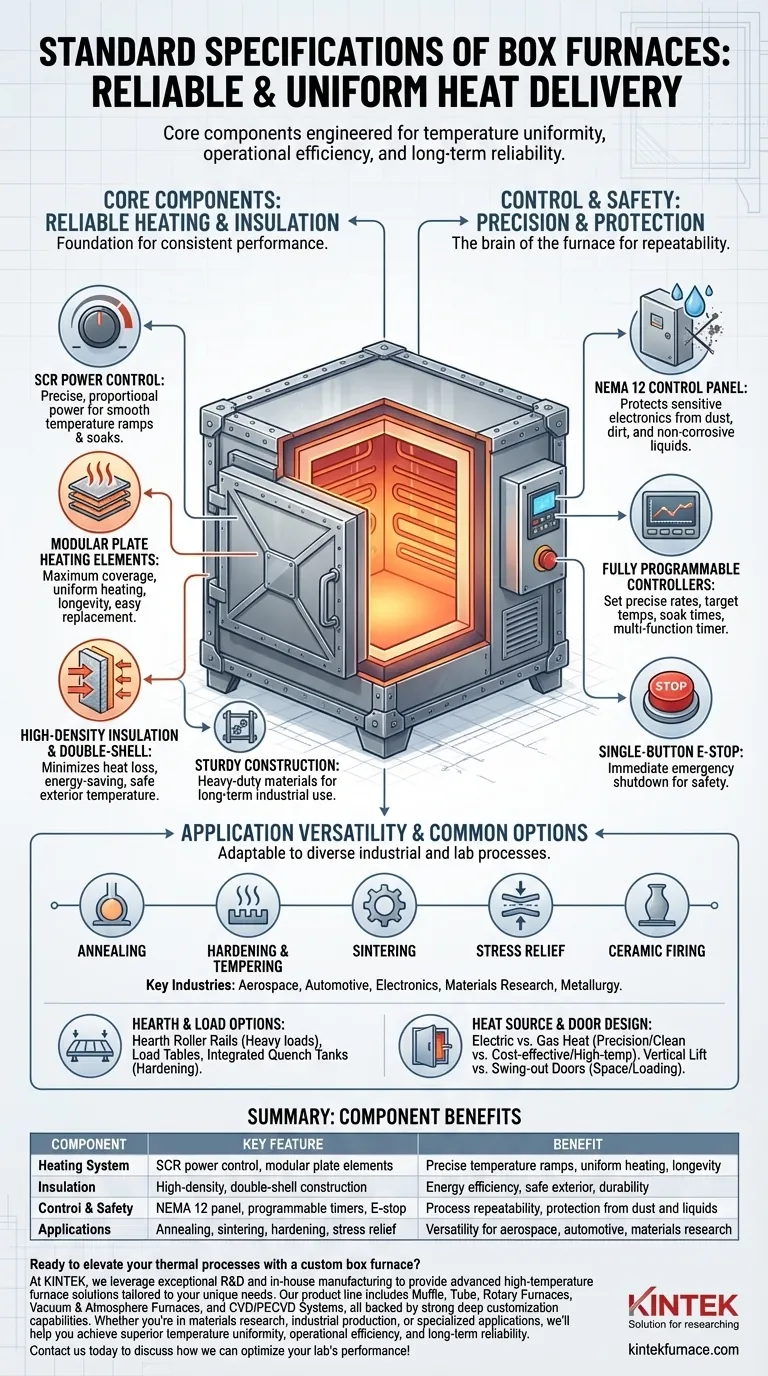

At their core, standard box furnaces are designed to deliver reliable and uniform heat within a controlled environment. Key specifications typically include electric heating elements engineered for maximum coverage, precise SCR (Silicon Controlled Rectifier) power control, a NEMA 12 rated control panel, programmable timers, and high-density, energy-saving insulation. These components work together to ensure consistent performance for various industrial and laboratory applications.

The collection of "standard specifications" is not just a feature list; it is a design philosophy focused on achieving three primary goals: temperature uniformity, operational efficiency, and long-term reliability for demanding thermal processes.

Core Components for Reliable Heating

Understanding the function of each standard component is key to evaluating a furnace's suitability for your specific task. These features are the foundation of its performance.

Heating System: Power and Uniformity

The heart of any furnace is its ability to generate and distribute heat evenly. Standard designs prioritize this through carefully selected components.

Electric heating elements are arranged to provide maximum heat coverage across the entire chamber, eliminating hot and cold spots that can compromise results.

Many high-quality furnaces use modular plate heating elements, which are known for their longevity and ease of replacement, minimizing downtime.

Power is managed by an SCR control system. Unlike simple on/off controls, SCRs provide fully proportional power, enabling smooth, precise temperature ramps and soaks critical for sensitive processes.

Insulation and Construction: Efficiency and Durability

A furnace's efficiency and lifespan are directly tied to its physical construction and insulation.

High-density, energy-saving insulation is used to minimize heat loss. This not only reduces operating costs but also ensures the furnace's exterior remains at a safe temperature.

Modern furnaces often feature a double-shell construction. This design promotes air circulation around the inner chamber, further enhancing temperature uniformity and keeping the outer shell cool.

Extra sturdy construction with heavy-duty materials ensures the furnace can withstand the rigors of long-term industrial use, from the frame to the door mechanisms.

Control and Safety: Precision and Protection

The control system is the brain of the furnace, providing the precision and safety required in professional settings.

A NEMA 12 control panel is standard for a reason. This enclosure protects the sensitive electrical components from dust, dirt, and dripping non-corrosive liquids common in industrial environments.

Fully programmable controllers allow users to set precise heating rates, target temperatures, soak times, and cooling rates, ensuring process repeatability. A multi-function electronic timer is a key part of this package.

Essential safety features like a single-button E-stop (Emergency Stop) are included to immediately shut down all operations in an emergency.

Understanding Application Versatility

Box furnaces are not a one-size-fits-all solution; their standard features make them adaptable to a wide array of thermal processes across numerous industries.

Common Industrial and Lab Processes

The precise temperature control and robust nature of these furnaces make them ideal for applications such as:

- Annealing: Softening metals to improve ductility and relieve internal stresses.

- Hardening & Tempering: A two-step process to increase the hardness of steel and then reduce its brittleness.

- Sintering: Fusing powdered materials together using heat, common in metallurgy and ceramics.

- Stress Relief: Reducing internal stresses in a part caused by manufacturing processes like welding or machining.

- Ceramic Firing: Firing clay, glass, and glazes in laboratory or art settings.

Key Industries Served

Because of this versatility, box furnaces are a staple in sectors like aerospace, automotive, electronics, materials research, and metallurgy.

Common Options and Trade-offs

While standard specifications provide a strong baseline, you must consider the options and trade-offs that tailor the furnace to your specific workflow.

Customizing for Your Process

Optional features can dramatically improve efficiency and expand capability. These include hearth roller rails for easily loading heavy parts, integrated quench tanks for hardening processes, and dedicated load tables.

Electric vs. Gas Heat

While most standard lab and precision furnaces are electric, some industrial models offer fully proportional gas heat. Gas can be more cost-effective for large-scale, high-temperature operations, but electric heat generally provides finer temperature control and a cleaner atmosphere.

Evaluating Door and Hearth Design

Furnace doors are typically available in vertical lift or swing-out configurations, a choice that depends on available floor space and loading methods. The hearth itself may be a flat surface or feature heavy-duty cast piers to support heavy or unusually shaped loads.

Making the Right Choice for Your Goal

Selecting the right furnace depends entirely on matching its capabilities to your primary application.

- If your primary focus is high-precision materials research: Prioritize furnaces with advanced programmable controllers, documented temperature uniformity, and clean electric heating elements.

- If your primary focus is high-volume industrial production: Emphasize robust construction, energy-efficient insulation, and options like hearth rollers that improve workflow and durability.

- If your primary focus is a specialized process like hardening or sintering: Evaluate the need for optional equipment like quench tanks or the benefits of a gas-fired system for your specific material.

Ultimately, understanding these standard specifications empowers you to look beyond the marketing and select a tool truly engineered for your work.

Summary Table:

| Component | Key Feature | Benefit |

|---|---|---|

| Heating System | SCR power control, modular plate elements | Precise temperature ramps, uniform heating, longevity |

| Insulation | High-density, double-shell construction | Energy efficiency, safe exterior, durability |

| Control & Safety | NEMA 12 panel, programmable timers, E-stop | Process repeatability, protection from dust and liquids |

| Applications | Annealing, sintering, hardening, stress relief | Versatility for aerospace, automotive, materials research |

Ready to elevate your thermal processes with a custom box furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities. Whether you're in materials research, industrial production, or specialized applications, we'll help you achieve superior temperature uniformity, operational efficiency, and long-term reliability. Contact us today to discuss how we can optimize your lab's performance!

Visual Guide

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What morphological changes occur in POMOF after treatment? Unlock High Catalytic Performance via Thermal Evolution

- What is the core function of a high-temperature muffle furnace in silver nanoparticle circuits? Optimize Conductivity

- What functions does a high-temperature muffle furnace perform during cathode precursor processing?