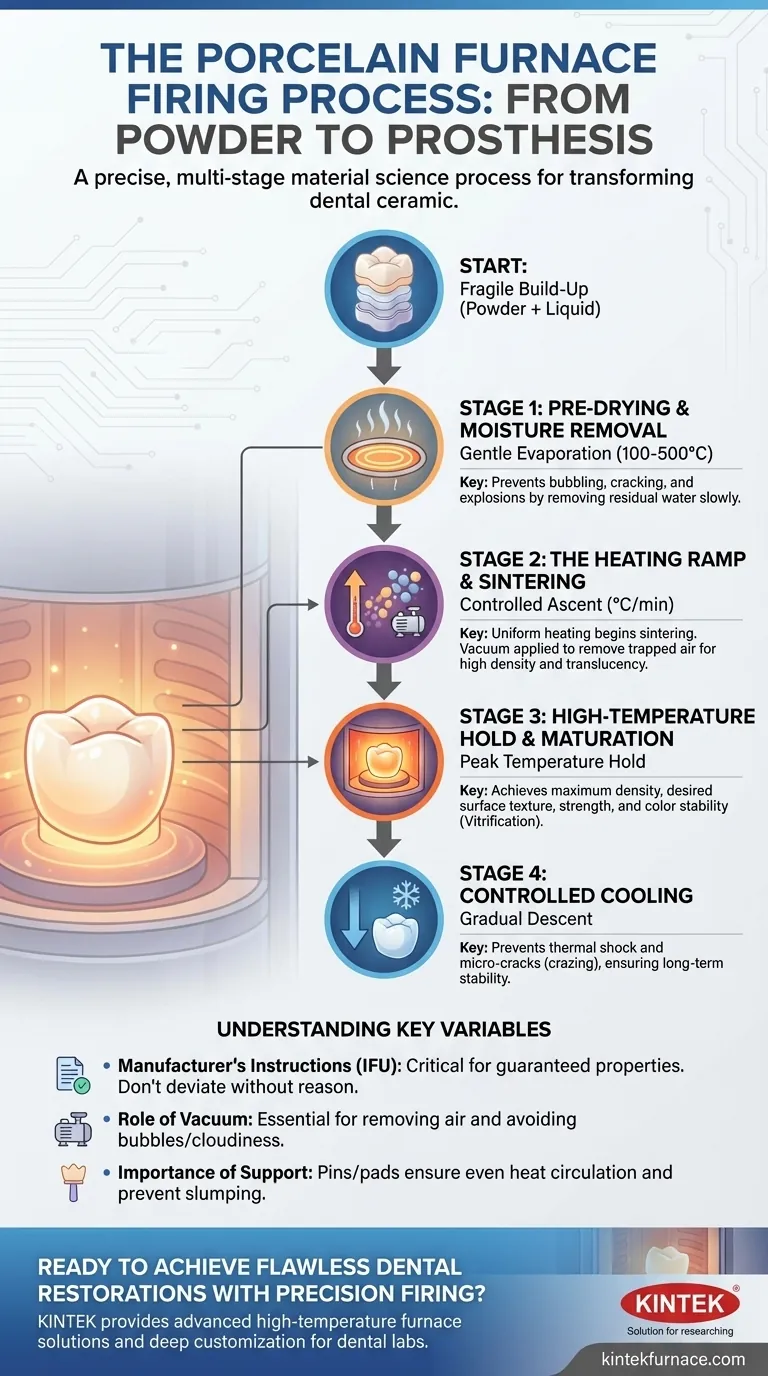

In short, the porcelain firing process consists of four critical stages: pre-drying to remove moisture, a controlled heating ramp to begin sintering, a high-temperature hold to achieve full maturation and density, and a controlled cooling phase to prevent thermal shock and cracking. Each stage is meticulously controlled by the furnace to transform loose ceramic powder into a strong, aesthetic, and durable dental restoration.

The core principle to grasp is that firing porcelain is not simply a matter of heating and cooling. It is a precise, multi-stage material science process designed to control the transformation of ceramic particles into a solid, vitrified mass with optimal physical and aesthetic properties.

The Goal of Firing: From Powder to Prosthesis

Before examining the stages, it's crucial to understand the objective. The entire firing cycle is engineered to achieve a specific physical transformation known as sintering.

The Starting Point: A Fragile Build-Up

A dental technician begins with layers of fine porcelain particles mixed with a liquid modeling agent. At this point, the restoration is incredibly fragile, holding its shape only due to the surface tension of the liquid.

The Objective: Sintering and Vitrification

Sintering is the process of fusing these particles together using heat, but at a temperature below the material's melting point. As the particles bond, the spaces between them shrink, resulting in a dense, hard, and strong final restoration. This process, also called vitrification, is what gives dental porcelain its signature glass-like properties.

The Result: A Strong and Stable Restoration

A successful firing cycle eliminates porosity and internal defects. This creates a restoration with optimal density, hardness, and color stability, ensuring its strength and long-term clinical success.

Deconstructing the Firing Cycle: A Stage-by-Stage Analysis

Modern porcelain furnaces automate these stages, but understanding each one is key to troubleshooting issues and achieving predictable results.

Stage 1: Pre-Drying and Moisture Removal

The cycle begins with the furnace platform raising the restoration into the chamber, which is held at a relatively low temperature (e.g., 100-500°C). This phase gently evaporates any residual water from the porcelain build-up.

Rushing this stage is a common cause of failure. If heated too quickly, trapped water will turn to steam, creating internal pressure that can cause the porcelain to bubble, crack, or even explode.

Stage 2: The Heating Ramp (Rate of Climb)

Once drying is complete, the furnace begins increasing the temperature at a controlled rate, often measured in degrees per minute (°C/min). This gradual increase ensures the entire restoration heats uniformly, preventing thermal stress between the outer and inner layers.

During this ramp, the sintering process begins, and the porcelain particles start to fuse. Many modern cycles apply a vacuum during this stage to remove air trapped between particles, which is essential for achieving high translucency and density.

Stage 3: The High-Temperature Hold (Maturation)

The furnace reaches a pre-determined peak temperature and holds it for a specific duration. This is the maturation or sintering phase, where the most critical chemical and physical changes occur.

Holding at this high heat allows the porcelain to reach its maximum density and desired surface texture (e.g., glaze). The exact temperature and time are dictated by the specific ceramic manufacturer to achieve the intended translucency, value, and chroma.

Stage 4: Controlled Cooling

After the hold time is complete, the temperature must be brought down carefully. Cooling too quickly will induce thermal shock, creating micro-cracks (crazing) that compromise the restoration's strength and aesthetics.

The furnace controls the cooling rate, often holding at certain temperatures to allow the crystalline and glass structures within the porcelain to stabilize before the chamber is fully opened.

Understanding the Key Variables

While furnaces feature pre-set programs, a true technician understands the variables that influence the outcome.

The Manufacturer's Instructions

The single most important variable is the Instructions For Use (IFU) from the porcelain manufacturer. Pre-programmed firing cycles are not arbitrary; they are the result of extensive testing to guarantee specific material properties. Deviating from them without a clear reason is a risk.

The Role of Vacuum

As mentioned, a vacuum is not a luxury but a necessity for high-quality restorations. By removing the atmosphere from the chamber during the heating ramp, it prevents air from becoming trapped in the fusing porcelain, which would otherwise appear as bubbles or cloudiness.

The Importance of Support

The references correctly note that restorations are placed on supports like pins, mesh, or firing pads. This is not just for convenience. Proper support allows heat to circulate evenly around the entire restoration and prevents it from slumping or distorting under its own weight at high temperatures.

Making the Right Choice for Your Goal

Understanding the purpose of each stage allows you to diagnose and perfect your results.

- If your primary focus is avoiding cracks and remakes: Pay close attention to a sufficient pre-drying time and a controlled, gradual cooling cycle.

- If your primary focus is aesthetics and translucency: Ensure the vacuum pump is functioning correctly and the cycle pulls a strong vacuum during the heating ramp.

- If your primary focus is achieving accurate shade and strength: Adhere precisely to the manufacturer's recommended high-temperature hold time and peak temperature.

Mastering these stages transforms the firing process from a routine task into a predictable science, giving you ultimate control over the final outcome.

Summary Table:

| Stage | Purpose | Key Details |

|---|---|---|

| Pre-Drying | Remove moisture | Prevents bubbling and cracking by evaporating water at 100-500°C |

| Heating Ramp | Begin sintering | Controlled temperature increase with vacuum for uniform heating and density |

| High-Temperature Hold | Achieve maturation | Holds peak temperature for optimal density, translucency, and strength |

| Controlled Cooling | Prevent thermal shock | Gradual cooling to avoid micro-cracks and ensure stability |

Ready to achieve flawless dental restorations with precision firing? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for dental labs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Enhance your lab's efficiency and results — contact us today to discuss how our furnaces can transform your porcelain firing process!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab