In a research context, a box furnace is a foundational tool used to subject materials to precise, high-temperature profiles. Its primary applications revolve around heat treatment, material synthesis, and analytical testing, making it indispensable in metallurgy, ceramics, and materials science for creating and evaluating novel materials.

A box furnace's value in research is defined by its ability to provide uniform heating to multiple samples or larger objects in a controlled atmospheric environment. This makes it the default choice for batch processing, general heat treatments, and material synthesis where sample geometry is not a limiting factor.

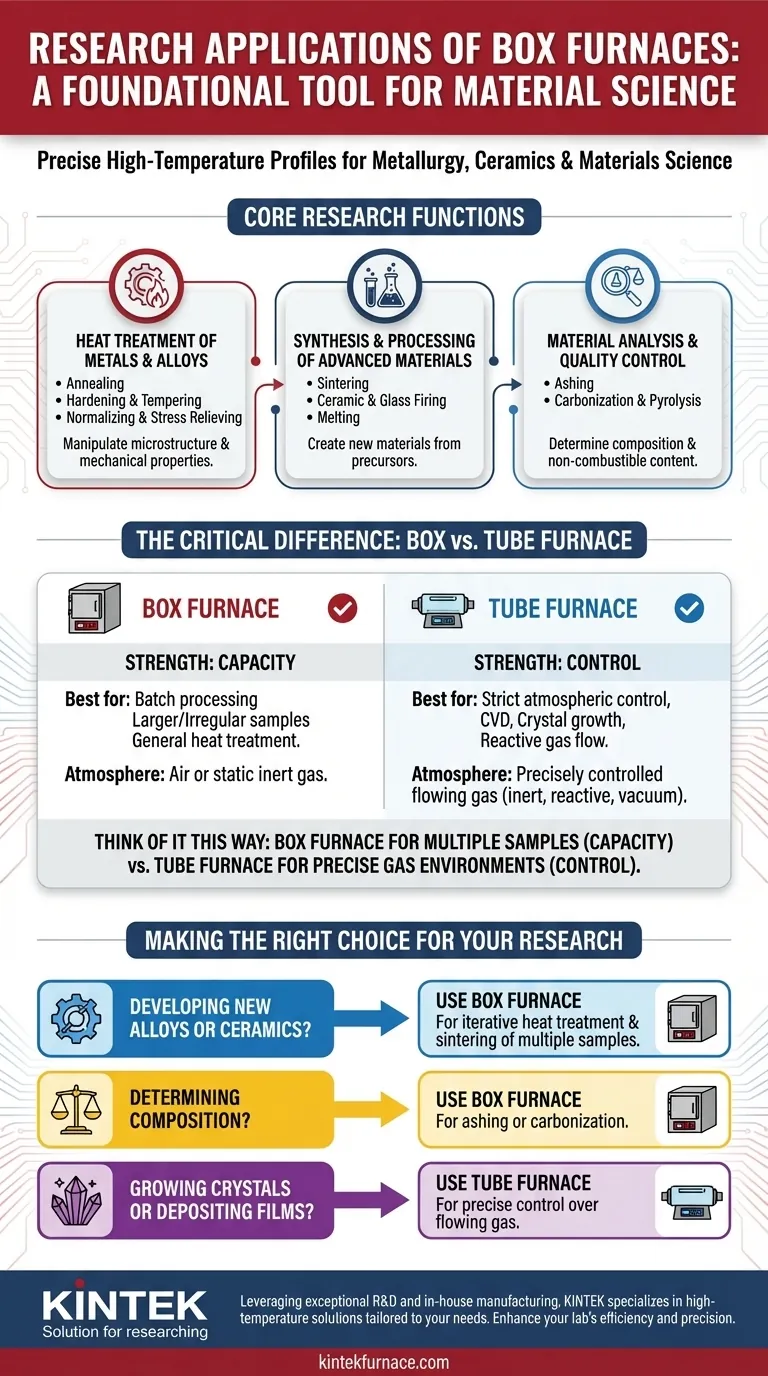

Core Research Functions of a Box Furnace

A box furnace, also known as a muffle furnace, is essentially a thermally insulated chamber with resistive heating elements. This simple design enables a wide range of fundamental scientific processes.

Heat Treatment of Metals and Alloys

This is one of the most common uses in metallurgical research. By controlling the heating and cooling cycles, researchers can precisely manipulate the microstructure and mechanical properties of metals.

- Annealing: Heats and slowly cools a metal to soften it, relieve internal stresses, and improve its ductility for further processing.

- Hardening & Tempering: Involves rapid cooling (quenching) after heating to increase hardness, followed by reheating to a lower temperature (tempering) to improve toughness and reduce brittleness.

- Normalizing & Stress Relieving: Aims to create a more uniform and predictable grain structure, removing internal stresses induced by manufacturing or welding.

Synthesis and Processing of Advanced Materials

Box furnaces are workhorses for creating new materials from precursor powders or solids, particularly in ceramics and composites research.

- Sintering: Heats compacted powders below their melting point, causing particles to bond and fuse. This is a critical step in creating dense, high-strength ceramic or metallic parts.

- Ceramic & Glass Firing: Used to fire ceramic green bodies or fuse glass components, transforming them into hard, durable final products.

- Melting: For lower-temperature alloys or glasses, a box furnace can be used for melting and casting small batches for experimental purposes.

Material Analysis and Quality Control

The furnace's ability to create a controlled, high-temperature environment is also used to analyze the composition of a sample.

- Ashing: Involves heating a sample in the presence of air to burn off all organic and volatile components, leaving only the inorganic ash. This is a standard method for determining the non-combustible content of a material.

- Carbonization & Pyrolysis: Heats organic matter in a low-oxygen or inert environment to produce a carbon-rich solid. This is fundamental to creating specialized carbon materials.

Understanding the Trade-offs: Box Furnace vs. Tube Furnace

Choosing the right furnace is critical for experimental success. The primary alternative to a box furnace in research is a tube furnace, and the choice between them hinges on atmosphere and sample geometry.

When to Choose a Box Furnace

A box furnace excels in batch processing and handling larger or irregularly shaped samples. Its spacious chamber provides excellent temperature uniformity for processing many samples at once, such as in crucibles.

It is the ideal tool for general-purpose annealing, ashing, sintering, and other heat treatments where the standard air atmosphere is acceptable or a static inert gas environment is sufficient.

When to Choose a Tube Furnace

A tube furnace is the superior choice for processes requiring strict atmospheric control. Its narrow tube design allows for a precisely controlled, flowing gas environment (inert, reactive, or vacuum).

This makes it essential for applications like Chemical Vapor Deposition (CVD), crystal growth, and specific types of synthesis or pyrolysis where reactions with a process gas are part of the experiment.

The Critical Difference: Capacity vs. Control

Think of the trade-off this way: a box furnace offers capacity, while a tube furnace offers atmospheric precision. If you need to heat treat a dozen metal samples in air, use a box furnace. If you need to grow a single crystal under a flowing argon shield, you must use a tube furnace.

Making the Right Choice for Your Research

Your experimental goal dictates your choice of equipment. By aligning the tool to the task, you ensure your results are valid and repeatable.

- If your primary focus is developing new metal alloys or ceramics: A box furnace is ideal for the iterative heat treatment, sintering, and annealing of multiple samples.

- If your primary focus is determining the composition of materials: A box furnace is the standard tool for ashing or carbonization to measure the inorganic or carbon content of a sample.

- If your primary focus is growing crystals or depositing thin films: A tube furnace is the superior choice due to its precise control over a flowing gas atmosphere.

By understanding the fundamental strengths of each furnace type, you can select the precise tool needed to advance your material science discovery.

Summary Table:

| Application Area | Key Functions | Common Uses |

|---|---|---|

| Heat Treatment | Annealing, hardening, tempering | Metal alloy development, stress relief |

| Material Synthesis | Sintering, firing, melting | Ceramic and composite creation |

| Material Analysis | Ashing, carbonization, pyrolysis | Quality control, composition testing |

Need a reliable furnace for your research? KINTEK specializes in high-temperature solutions tailored to your needs. Leveraging exceptional R&D and in-house manufacturing, we offer advanced box furnaces, tube furnaces, and more, with deep customization to meet unique experimental requirements. Enhance your lab's efficiency and precision—contact us today to discuss how our products can support your material science discoveries!

Visual Guide

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the core function of a muffle furnace in biomass activation? Optimize Carbonization & Pore Development

- How does high-temperature heating facilitate the conversion of rice husks into inorganic precursors for silica extraction?

- What is the function of a high-temperature muffle furnace in HZSM-5 preparation? Master Catalytic Activation

- How does a high-temperature muffle furnace contribute to the thermal treatment process of chalcopyrite ore?

- What is the function of a high-temperature muffle furnace in ZnO-SP preparation? Master Nanoscale Synthesis Control