At their core, the maintenance benefits of an indirectly fired rotary kiln stem directly from its design simplicity. By heating the kiln externally, the internal mechanics are dramatically simplified, protecting the system from the harsh conditions of direct combustion. This separation of the heating source from the material being processed reduces wear, minimizes potential points of failure, and streamlines operational oversight.

The fundamental advantage is clear: separating the combustion process from the material chamber eliminates internal fuel-related components and corrosive byproducts. This simplified internal environment is the primary driver of lower maintenance, increased reliability, and a more predictable operational lifecycle.

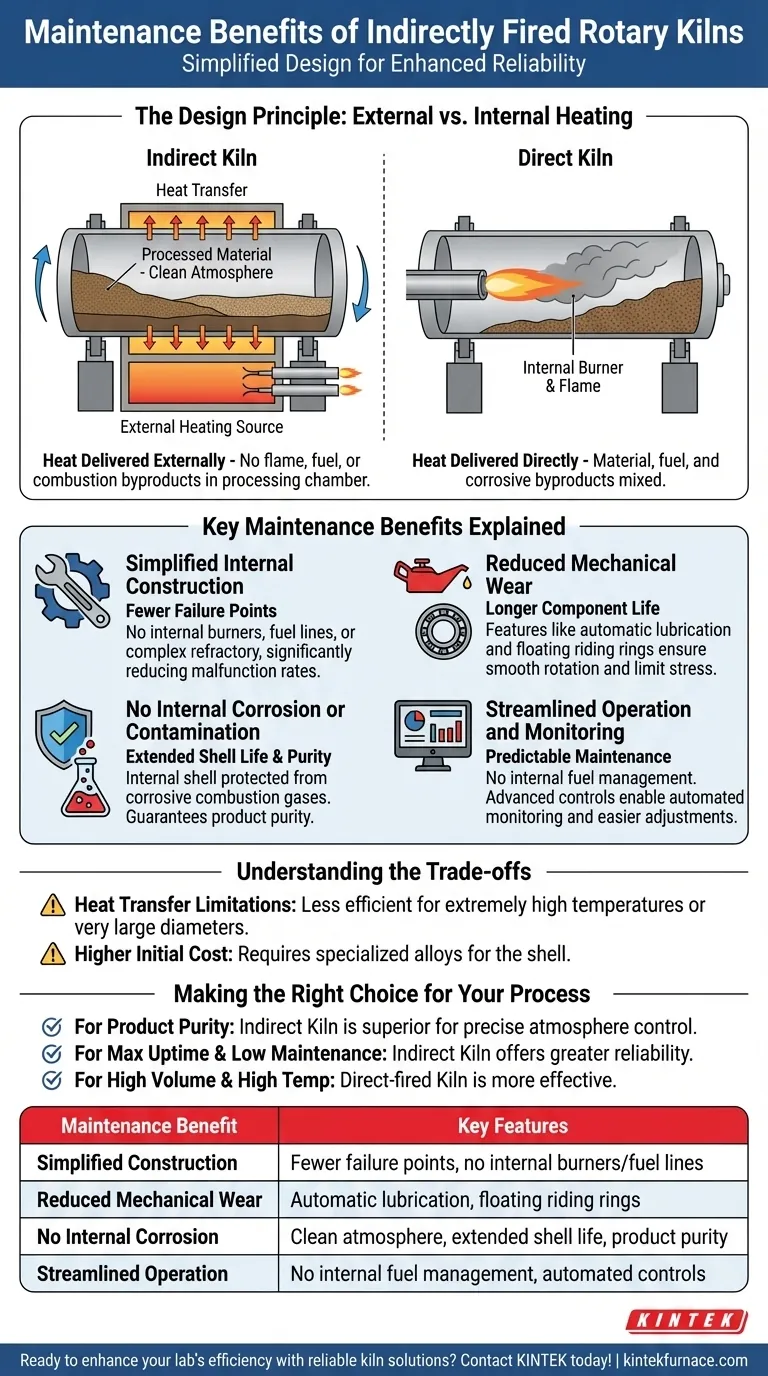

The Design Principle: External vs. Internal Heating

To grasp the maintenance benefits, you must first understand the fundamental difference in how heat is delivered. This single design choice dictates the entire operational and maintenance profile of the kiln.

How an Indirect Kiln Works

An indirect kiln operates much like a pot on a stove. The rotating drum, or shell, is heated from the outside by an external furnace or heating jacket. The heat then transfers through the metal shell to the material tumbling inside.

There is no flame, fuel, or combustion gas inside the processing chamber. This creates a clean, controlled, and non-reactive atmosphere for the material.

How a Direct Kiln Differs

In a direct-fired kiln, the burner is located inside the kiln itself. The flame and hot combustion gases pass directly over and through the material to transfer heat.

This means the material, the fuel, and its byproducts (like ash and corrosive gases) are all mixed together within the same environment.

Key Maintenance Benefits Explained

The external heating design of an indirect kiln creates several distinct and powerful maintenance advantages.

Simplified Internal Construction

Without the need for internal burners, fuel lines, or related refractory structures to protect against flame impingement, the kiln's internal design is fundamentally simpler.

This simplification directly translates to fewer failure points. There are simply fewer components inside the hot zone that can break, clog, or wear out, which significantly reduces malfunction rates.

Reduced Mechanical Wear

Indirect kilns are often built with a heavy-duty design philosophy. Features like an automatic lubrication system ensure that rotating parts like riding rings and trunnion wheels move continuously and smoothly.

This, combined with fully floating or tangentially suspended riding rings, ensures smooth rotation, minimizes stress on the drive system, and limits component wear over the long term.

No Internal Corrosion or Contamination

Because fuel is not burned inside the kiln, the internal shell is not exposed to corrosive combustion gases or abrasive ash.

This prevents material degradation of the kiln shell, extending its operational life and eliminating the maintenance burden associated with damage from a harsh internal atmosphere. It also guarantees product purity, as the material is never contaminated by fuel byproducts.

Streamlined Operation and Monitoring

Operation is simplified because there is no complex fuel management or air-to-fuel ratio to control inside the kiln. The focus shifts to managing the external furnace and the material feed rate.

Furthermore, advanced control systems and sensors enable automated monitoring and adjustments. This makes maintenance tasks more predictable and manageable, lowering the overall operational effort.

Understanding the Trade-offs

While offering significant maintenance advantages, the indirect kiln design is not universally superior. Objectivity requires acknowledging its limitations.

Heat Transfer and Scale Limitations

Transferring heat through a solid steel shell is less efficient than direct contact with hot gas. As a result, indirect kilns are generally not suited for processes requiring extremely high temperatures or for very large-diameter kilns, where heat struggles to penetrate to the center of the material bed.

Shell Material and Cost

The kiln shell itself must act as a heat exchanger. This requires it to be constructed from specialized alloys capable of withstanding high external temperatures and thermal stress without deforming. This can increase the initial capital cost compared to a standard carbon steel direct-fired kiln.

The External Furnace

The maintenance burden is not eliminated, but rather shifted. While the kiln itself is simpler, the external furnace or heating chamber becomes a separate, critical piece of equipment that requires its own maintenance schedule for its burners, refractory, and controls.

Making the Right Choice for Your Process

Selecting the correct kiln technology requires aligning the design's inherent strengths with your primary operational goal.

- If your primary focus is product purity and precise atmosphere control: An indirect kiln is the superior choice, as it completely isolates the material from combustion byproducts.

- If your primary focus is maximizing uptime and minimizing operational costs: The simpler internal design and fewer failure points of an indirect kiln lead to greater reliability and lower long-term maintenance needs.

- If your primary focus is high-volume throughput at very high temperatures: A direct-fired kiln is often more effective and economical due to its more efficient method of heat transfer.

Understanding these fundamental design differences empowers you to select the technology that best aligns with your long-term operational and financial goals.

Summary Table:

| Maintenance Benefit | Key Features |

|---|---|

| Simplified Internal Construction | Fewer failure points, no internal burners or fuel lines |

| Reduced Mechanical Wear | Automatic lubrication, floating riding rings for smooth operation |

| No Internal Corrosion or Contamination | Clean atmosphere, extended shell life, product purity |

| Streamlined Operation and Monitoring | No internal fuel management, automated controls for predictability |

Ready to enhance your lab's efficiency with reliable kiln solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions, including indirectly fired rotary kilns. Our product line, such as Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capability to precisely meet your unique experimental needs. Contact us today to discuss how we can reduce your maintenance costs and boost uptime!

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

People Also Ask

- How do vibrational feeder specifications impact rotary kiln efficiency? Optimize Your Lab's Material Flow & Stability

- What data is necessary to design a rotary kiln? Essential Factors for Efficient Thermal Processing

- What role does gas flow and combustion play in a rotary kiln? Optimize Heat Transfer for Efficiency and Quality

- What distinguishes direct from indirect rotary kilns? Choose the Right Kiln for Your Material

- What are the primary applications of an electric rotary kiln? Achieve High-Purity Material Processing with Precision