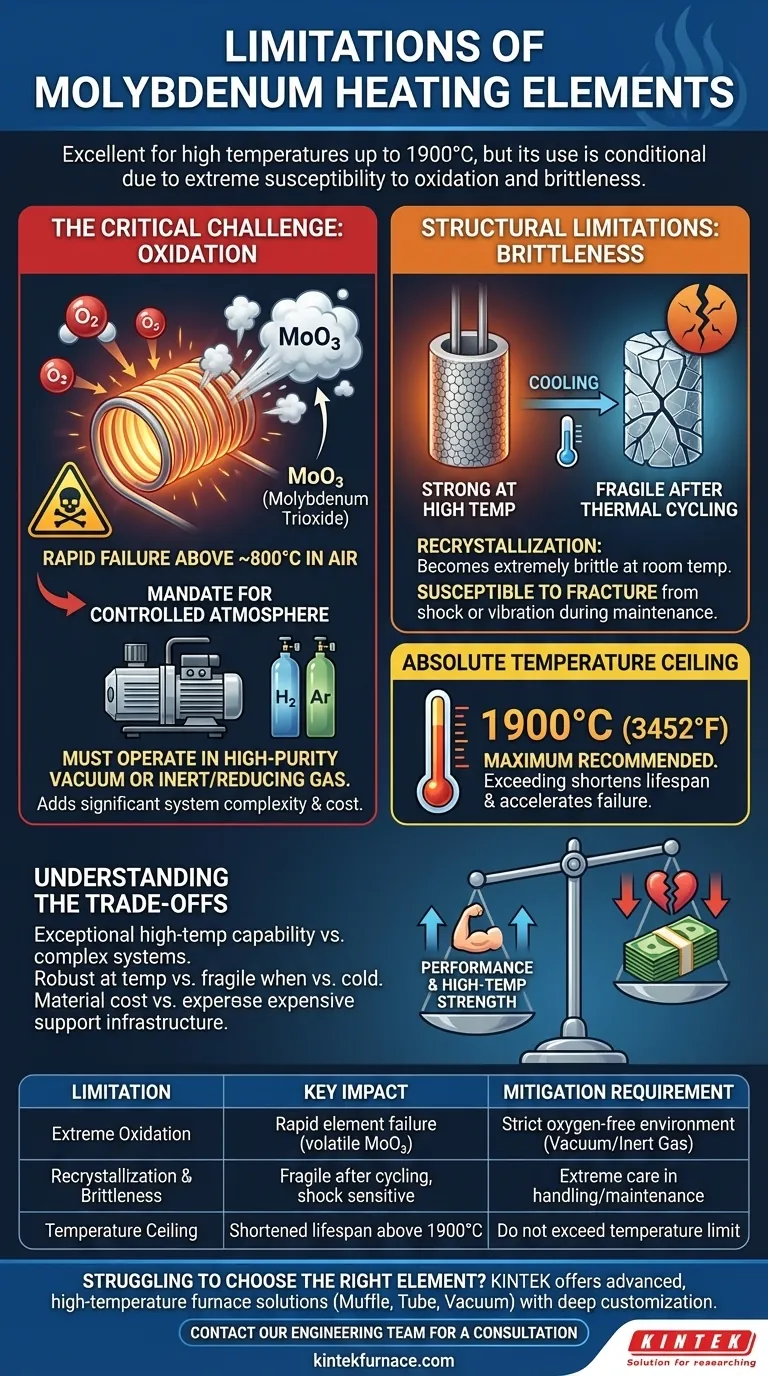

While an excellent material for high-temperature applications, molybdenum's primary limitations are its extreme susceptibility to oxidation and its tendency to become brittle after thermal cycling. It cannot be operated in the presence of oxygen at high temperatures, which mandates the use of a vacuum or a protective, inert atmosphere.

Molybdenum is a highly capable heating element for temperatures up to 1900°C, but its use is conditional. Its profound weakness to oxidation requires a strictly controlled, oxygen-free environment, making it a specialized material rather than a general-purpose solution.

The Critical Challenge: Oxidation

Molybdenum’s most significant drawback is its reaction with oxygen. This single characteristic dictates the entire design and operation of any furnace that uses it.

Why Oxidation is Catastrophic

At elevated temperatures, molybdenum reacts rapidly with any available oxygen. This isn't a slow corrosion process; it's an aggressive chemical reaction.

The reaction forms molybdenum trioxide (MoO₃), a compound that is volatile above approximately 800°C. This means the protective oxide layer doesn't just form—it evaporates, exposing fresh metal to be oxidized in a rapidly repeating cycle.

The Consequence: Rapid Failure

This process of "volatile oxidation" leads to a swift reduction in the heating element's cross-section. The element literally disappears over time, leading to premature and catastrophic failure.

The Mandate for a Controlled Atmosphere

To prevent this, molybdenum heating elements must operate in a high-purity vacuum. Alternatively, they can be used in a reducing atmosphere (like dry hydrogen) or an inert gas atmosphere (like argon). This requirement adds significant complexity and cost to the overall system design.

Understanding the Structural Limitations

Beyond its chemical vulnerability, molybdenum's physical properties also change in ways that impose limitations on its use.

Recrystallization and Brittleness

As molybdenum is heated to its operational range, its internal grain structure changes in a process called recrystallization.

While strong at high temperatures, this new grain structure makes the metal extremely brittle and fragile once it cools back down to room temperature.

The Impact on Handling and Maintenance

A "recrystallized" molybdenum element is highly susceptible to fracture from mechanical shock or even slight vibrations.

This means extreme care must be taken during furnace maintenance or when moving the system. An accidental bump that would be harmless to other materials can easily shatter a molybdenum element after it has been used.

The Absolute Temperature Ceiling

The maximum recommended operating temperature for molybdenum is 1900°C (3452°F). Pushing the element beyond this temperature significantly shortens its lifespan, accelerates recrystallization, and increases the risk of mechanical failure.

Understanding the Trade-offs

Choosing molybdenum involves a clear set of compromises that you must weigh for your specific application.

Performance vs. Complexity

You gain exceptional high-temperature capability, but at the cost of installing and maintaining a complex vacuum or controlled atmosphere system. Elements that operate in air, like silicon carbide, offer simplicity but cannot reach the same temperatures.

High-Temp Strength vs. Room-Temp Fragility

The material is robust and effective within its high-temperature operating window. However, its post-use brittleness at room temperature presents a significant risk during maintenance, potentially increasing long-term operational costs due to accidental breakage.

Material Cost vs. System Cost

While the cost of molybdenum wire or rod is one factor, the total cost of ownership is dominated by the supporting equipment. Vacuum pumps, gas management systems, and sophisticated controllers are all required to create the necessary operating environment.

Making the Right Choice for Your Application

Your final decision must be based on the non-negotiable requirements of your process.

- If your primary focus is reaching extreme temperatures (up to 1900°C) in a new, purpose-built system: Molybdenum is an excellent choice, provided you design for and maintain a high-purity vacuum or inert atmosphere.

- If your primary focus is operational simplicity or you require frequent maintenance access: The brittleness and atmosphere requirements of molybdenum make it a poor fit; consider alternatives that can operate in air.

- If your primary focus is minimizing upfront cost and system complexity: The extensive support infrastructure required for molybdenum often makes other materials a more economical and practical choice.

Understanding these inherent limitations is the key to leveraging molybdenum's power, ensuring both performance and reliability in your high-temperature process.

Summary Table:

| Limitation | Key Impact | Mitigation Requirement |

|---|---|---|

| Extreme Oxidation | Rapid formation of volatile MoO₃, leading to element failure | Strict oxygen-free environment (Vacuum/Inert Gas) |

| Recrystallization & Brittleness | Becomes fragile after thermal cycling, sensitive to shock | Extreme care during handling and maintenance |

| Temperature Ceiling | Maximum recommended operating temperature of 1900°C | Must not exceed temperature limit to avoid shortened lifespan |

Struggling to choose the right high-temperature heating element for your demanding application?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced, high-temperature furnace solutions. Our product line, including Muffle, Tube, and Vacuum & Atmosphere Furnaces, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Let our experts help you navigate the trade-offs between materials like molybdenum and alternatives to select the optimal heating element and furnace system for your specific process, ensuring performance, reliability, and value.

Contact our engineering team today for a personalized consultation!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How does a vacuum heat treatment furnace prevent contamination? Ensure Purity in High-Temperature Processes

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- Why should nitrogen not be used as a cooling gas for titanium alloys in vacuum heat treatment? Avoid Catastrophic Failures

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing