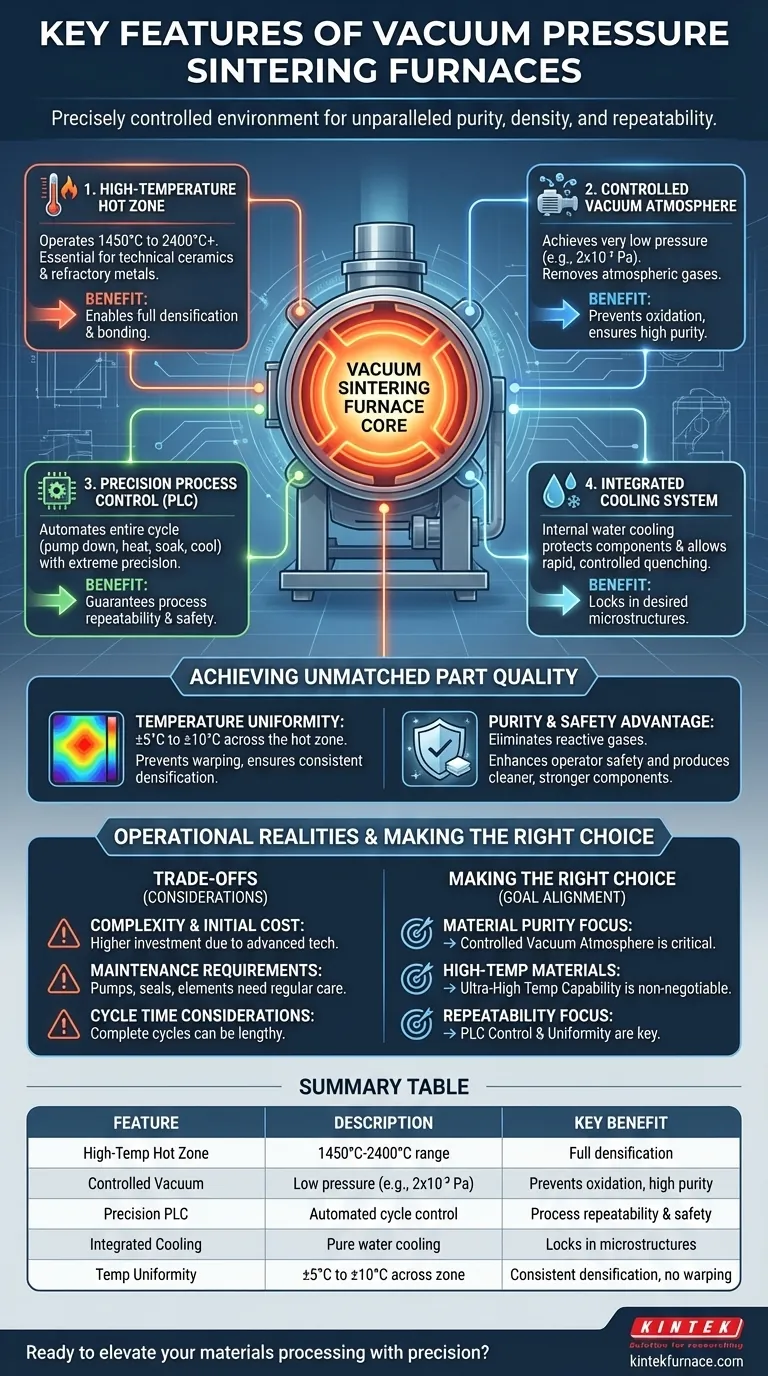

At their core, vacuum pressure sintering furnaces are defined by four key features. These are an ultra-high temperature hot zone, a highly controlled vacuum environment, a sophisticated PLC-based control system for process automation, and an integrated cooling system. Together, these elements enable the processing of advanced materials that are impossible to create using conventional atmospheric furnaces.

A vacuum pressure sintering furnace is not simply a high-temperature oven. It is a precisely controlled environment designed to manipulate temperature, pressure, and atmosphere to achieve specific material properties, delivering unparalleled purity, density, and process repeatability.

The Core Pillars of Vacuum Sintering

To understand the value of this technology, you must understand how its primary features work in concert. Each component addresses a fundamental challenge in materials science.

Feature 1: The High-Temperature Hot Zone

The furnace's primary function is to generate extreme heat. Most models operate in a range of 1450°C to 2400°C, with some capable of reaching even higher temperatures.

This capability is essential for sintering materials with very high melting points, such as technical ceramics, tungsten carbides, and other refractory metals. Without these temperatures, full densification and bonding cannot occur.

Feature 2: The Controlled Vacuum Atmosphere

Operating under a vacuum is what truly distinguishes this process. The system pumps out atmospheric gases to achieve very low pressures, sometimes as low as 2x10⁻³ Pa or less.

This near-total absence of oxygen prevents oxidation and other chemical reactions that would contaminate the material at high temperatures. It also helps pull out binders and other process by-products, resulting in a finished part with exceptionally high purity.

Feature 3: Precision Process Control (PLC)

Modern furnaces are governed by a Programmable Logic Controller (PLC). This computer control system manages every stage of the sintering cycle with extreme precision.

The PLC automates the complex sequences of pumping down to a vacuum, ramping up the temperature, holding a specific temperature (soaking), and cooling. This automation ensures that every production run is identical, providing unparalleled process repeatability. The PLC also integrates all safety monitoring systems.

Feature 4: Integrated Cooling System

Managing extreme heat also requires an effective cooling solution. These furnaces use an internal circulation pure water cooling system to protect the furnace body, seals, and power components from thermal damage.

Furthermore, this system allows for rapid and controlled cooling of the sintered part. This ability to quench the material at specific rates is critical for locking in desired microstructures and mechanical properties.

Achieving Unmatched Part Quality

The synergy of these features directly translates into superior product quality and reliability. The focus is less on heating and more on creating the perfect conditions for material transformation.

The Importance of Temperature Uniformity

A critical performance metric is temperature uniformity, often specified within ±5°C to ±10°C across the entire hot zone.

This ensures that the entire part, regardless of its geometry, is heated evenly. It prevents internal stresses, warping, or inconsistent densification, which are common failure points in less advanced furnaces.

The Purity and Safety Advantage

The vacuum environment is fundamental to both quality and safety. By eliminating atmospheric gases, the risk of fire or explosion from reactive materials is virtually nil.

This controlled environment enhances operator safety while simultaneously producing cleaner, stronger, and more reliable components by removing unwanted impurities during the heating process.

Understanding the Trade-offs and Operational Realities

While powerful, this technology comes with specific considerations that must be understood to ensure successful implementation and a positive return on investment.

Complexity and Initial Cost

Vacuum pressure sintering furnaces are sophisticated, high-precision instruments. Their initial acquisition cost is significantly higher than that of traditional atmospheric furnaces due to the vacuum pumps, advanced controls, and robust construction required.

Maintenance Requirements

The systems that create and maintain the vacuum environment, such as pumps, seals, and gauges, require regular, specialized maintenance. Heating elements and thermocouples also have a finite lifespan and must be periodically replaced to ensure performance and accuracy.

Cycle Time Considerations

A complete vacuum sintering cycle can be lengthy. The time required to pump the chamber down to the target vacuum level, heat to temperature, soak, and cool in a controlled manner can extend for many hours, which must be factored into production planning.

Making the Right Choice for Your Goal

Selecting the right equipment depends entirely on your end goal. The features of a vacuum sintering furnace directly address specific challenges in advanced manufacturing.

- If your primary focus is material purity and eliminating oxidation: The controlled vacuum atmosphere is the most critical feature, making this furnace technology essential.

- If you are working with high-performance ceramics or refractory metals: The ultra-high temperature capability is the non-negotiable feature you need.

- If your primary focus is process repeatability for high-volume production: The PLC control system and guaranteed temperature uniformity are the most important factors for ensuring consistent quality.

By understanding how these core features solve specific material processing challenges, you can confidently determine how this technology aligns with your project's goals.

Summary Table:

| Feature | Description | Key Benefit |

|---|---|---|

| High-Temperature Hot Zone | Operates at 1450°C to 2400°C for sintering high-melting-point materials | Enables full densification of ceramics and refractory metals |

| Controlled Vacuum Atmosphere | Achieves low pressures (e.g., 2x10⁻³ Pa) to remove atmospheric gases | Prevents oxidation, ensures high material purity |

| Precision Process Control (PLC) | Automated control of vacuum, temperature, and cooling cycles | Guarantees process repeatability and safety |

| Integrated Cooling System | Uses pure water cooling for rapid, controlled part cooling | Locks in desired microstructures and mechanical properties |

| Temperature Uniformity | Maintains ±5°C to ±10°C across the hot zone | Prevents warping and ensures consistent densification |

Ready to elevate your materials processing with precision and reliability? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Vacuum & Atmosphere Furnaces, Muffle, Tube, Rotary Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental requirements. Whether you're working with technical ceramics, refractory metals, or other advanced materials, our vacuum pressure sintering furnaces deliver unparalleled purity, density, and repeatability. Contact us today to discuss how we can optimize your lab's efficiency and achieve superior results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab