At their core, inert ovens are specialized tools for heating materials within a chemically non-reactive environment. Their key features are an airtight chamber, a system for purging reactive gases like oxygen, and precise temperature control. These components work together to replace the ambient atmosphere with an inert gas, such as nitrogen, preventing oxidation, contamination, and other unwanted chemical reactions during the heating process.

The true purpose of an inert oven is not merely to heat a product, but to meticulously control its chemical environment. Each feature is designed to systematically remove and block reactive elements—primarily oxygen and moisture—ensuring sensitive materials can undergo thermal processing without degradation.

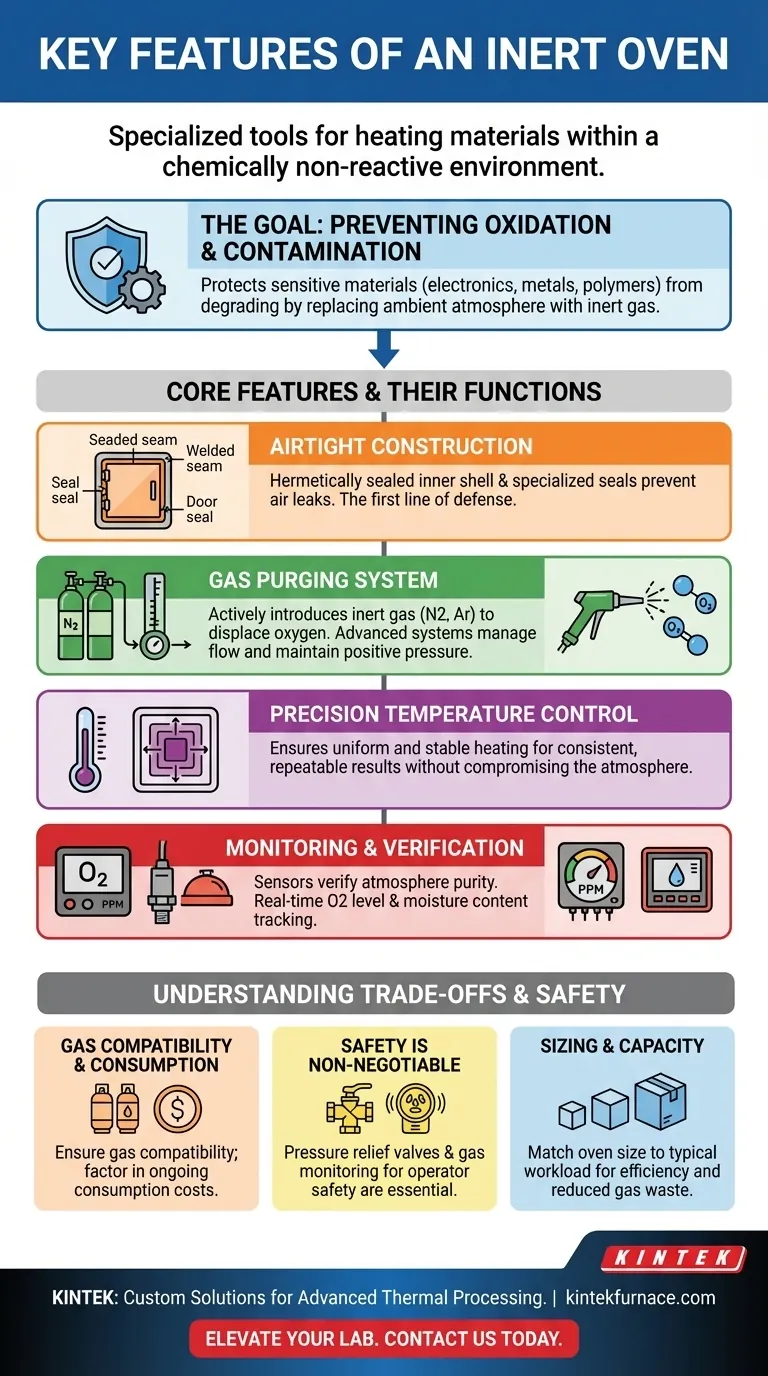

The Goal: Preventing Oxidation and Contamination

An inert oven’s primary function is to protect materials that are sensitive to oxygen or moisture, especially at elevated temperatures.

Why a Standard Oven Isn't Enough

In a standard oven, the presence of oxygen will cause many materials to oxidize, leading to degradation, discoloration, or a complete failure of the part or process. This is unacceptable when working with sensitive electronics, certain metals, polymers, and chemicals.

Creating a Controlled Atmosphere

The inert oven solves this by creating a sealed environment where the atmosphere can be modified. By purging the chamber with a dry, inert gas like nitrogen or argon, oxygen levels can be reduced to mere parts per million (PPM), effectively stopping these unwanted reactions.

Core Features and Their Functions

Each component of an inert oven plays a critical role in establishing and maintaining the non-reactive atmosphere.

Airtight Construction: The First Line of Defense

An inert oven must be hermetically sealed to prevent ambient air from leaking into the chamber. This is typically achieved with a continuously welded inner shell and specialized door seals. Without a truly airtight chamber, maintaining a pure inert atmosphere is impossible and inefficient.

The Gas Purging System: Actively Removing Oxygen

This system is the heart of the oven's atmospheric control. It introduces an inert gas (most commonly nitrogen) into the chamber to displace the oxygen-rich ambient air. Advanced systems use closed-loop flow control to precisely manage gas consumption and maintain a slight positive pressure, further preventing contamination.

Precision Temperature Control: Heating Without Compromise

Creating an inert atmosphere is only half the battle. The oven must also provide extremely uniform and stable temperatures. Precise thermal control ensures that the material is processed exactly as required, guaranteeing consistent and repeatable results.

Monitoring and Verification: Ensuring Purity

You cannot control what you cannot measure. Inert ovens incorporate sensors to verify the quality of the internal atmosphere.

- Oxygen Sensors: These analyzers provide real-time feedback on the oxygen level inside the chamber, confirming that the environment has reached the required purity for the process.

- Dew Point Monitors: For processes sensitive to moisture, these sensors measure the water vapor content, ensuring the inert gas is sufficiently dry.

Understanding the Trade-offs and Safety

While powerful, inert ovens require careful consideration of their operational parameters and safety implications.

Gas Compatibility and Consumption

While nitrogen is the most common choice, some materials may require other inert gases like argon. You must ensure the oven is compatible with your chosen gas. Furthermore, the purging process consumes gas, which is an ongoing operational cost that must be factored in.

Safety Is Non-Negotiable

Introducing pressurized gas into a sealed, heated chamber creates inherent risks. Key safety features are not optional.

- Pressure Relief Valves: These prevent the dangerous buildup of excess pressure inside the chamber.

- Gas Monitoring Systems: External sensors can monitor for leaks, protecting operators from potential asphyxiation hazards in poorly ventilated areas.

Sizing and Capacity

Selecting an oven that is too large for your typical workload leads to wasted inert gas and longer purge cycles. Conversely, an oven that is too small becomes a production bottleneck. The capacity should be carefully matched to the application's needs for optimal efficiency.

Making the Right Choice for Your Goal

Select an oven by prioritizing the features that best support your primary objective.

- If your primary focus is process consistency and quality control: Prioritize ovens with advanced, real-time oxygen and moisture sensors for process verification.

- If your primary focus is high-throughput production: Look for an oven with an efficient gas purging system and a tightly sealed chamber to minimize gas consumption and cycle times.

- If your primary focus is research and development: Select an oven with a wide, precise temperature range and compatibility with multiple inert gases to ensure maximum flexibility.

Understanding these core features empowers you to use an inert oven not just as a heater, but as a precise instrument for controlling chemical environments.

Summary Table:

| Feature | Function | Benefit |

|---|---|---|

| Airtight Construction | Seals chamber to prevent air leaks | Maintains inert atmosphere, prevents contamination |

| Gas Purging System | Introduces inert gas to displace oxygen | Reduces oxidation, ensures non-reactive environment |

| Precision Temperature Control | Provides uniform and stable heating | Guarantees consistent, repeatable results |

| Monitoring Sensors | Tracks oxygen levels and moisture | Verifies atmosphere purity for quality control |

| Safety Features | Includes pressure relief and gas leak detection | Protects operators and equipment from hazards |

Ready to elevate your lab's thermal processing with a custom inert oven? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, delivering purity, precision, and efficiency. Contact us today to discuss how we can optimize your processes and achieve superior results!

Visual Guide

Related Products

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What industries commonly use inert atmosphere heat treating? Key Applications in Military, Automotive, and More

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance