To prevent workpiece deformation in vacuum quenching, you must meticulously control three distinct stages: uniform heating, complete penetration heating (soaking), and precisely managed quenching. The fundamental goal is to minimize thermal gradients and internal stresses throughout the entire heat-treatment cycle, as uneven temperature changes are the direct cause of distortion.

The core challenge of vacuum quenching is that heat transfer occurs primarily through radiation, which can be non-uniform. Successfully preventing deformation requires supplementing radiative heating with gas convection and then precisely controlling the cooling rate to ensure the entire workpiece undergoes its metallurgical transformation as uniformly as possible.

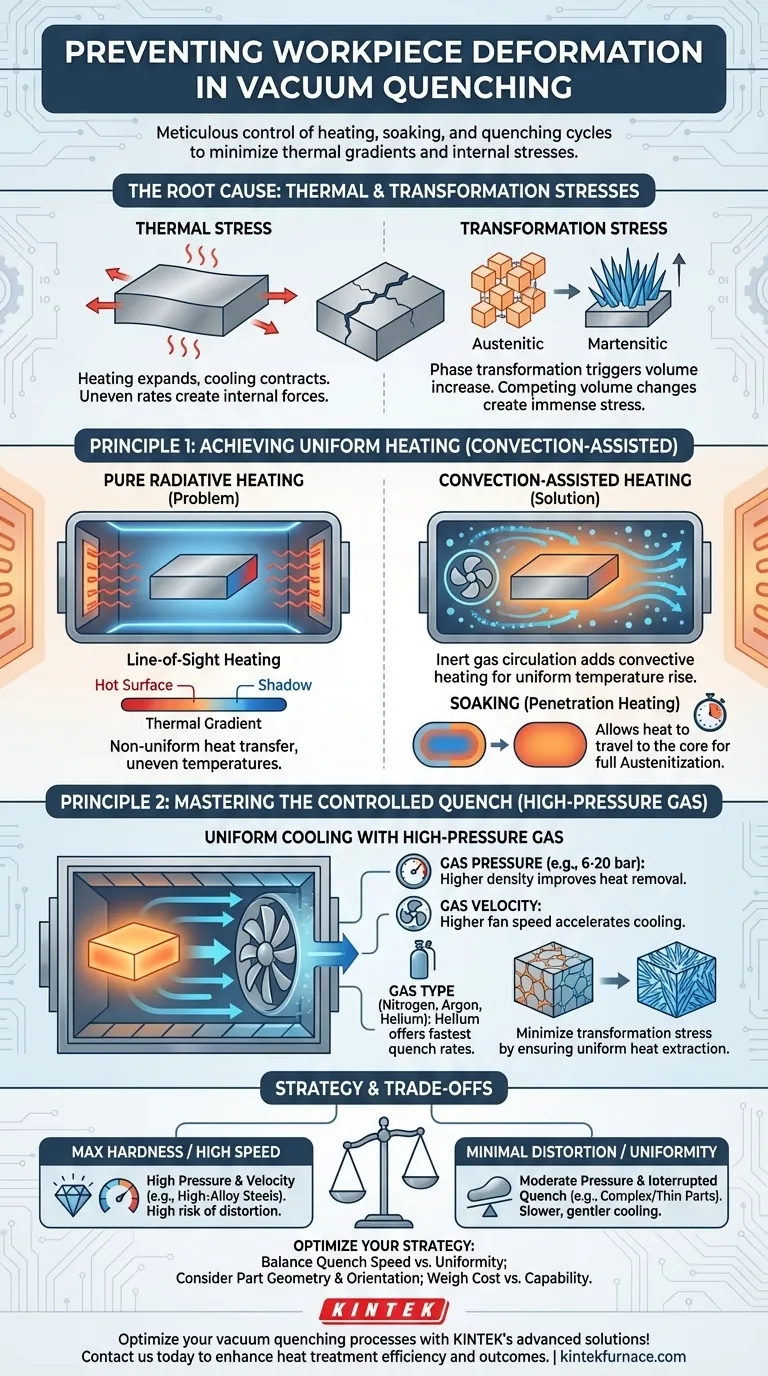

The Root Cause: Thermal and Transformation Stresses

Before addressing the solution, it's critical to understand the two forces that cause a workpiece to warp or crack during quenching.

Thermal Stress

As a metal is heated, it expands. As it cools, it contracts. If one part of the workpiece heats or cools faster than another, this difference in expansion or contraction creates internal forces. These forces, known as thermal stress, can be powerful enough to permanently deform the part.

Transformation Stress

For hardenable steels, the quenching process triggers a phase transformation from a crystalline structure called austenite to a very hard structure called martensite. This transformation is accompanied by a slight increase in volume. If the surface of the part transforms to martensite while the core is still hot and austenitic, the competing volume changes create immense internal transformation stress, a primary driver of distortion and quench cracking.

Principle 1: Achieving Uniform Heating

The first step in minimizing stress is ensuring the workpiece reaches the austenitizing temperature uniformly. In a vacuum, this presents a unique challenge.

The Problem with Pure Radiative Heating

In a high vacuum, heat is transferred almost exclusively by radiation from the furnace's heating elements. This can create "line-of-sight" heating, where surfaces directly facing the elements get hot much faster than surfaces that are shielded or in the "shadow." This immediately introduces a thermal gradient and internal stress.

The Solution: Convection-Assisted Heating

To counteract this, a low pressure of high-purity inert gas, typically nitrogen, is introduced into the hot zone. A fan circulates this gas, adding a convective heating component. The moving gas carries heat to all surfaces of the workpiece, even those not in the direct line of sight of the elements, promoting a much more uniform temperature rise.

The Importance of Soaking (Penetration Heating)

Once the surface of the part reaches the target temperature, it must be held there for a specific duration. This "soaking" period, also known as penetration heating, allows time for the heat to travel from the surface to the core of the workpiece. A proper soak ensures the entire cross-section is at a uniform temperature and has fully transformed into austenite, setting the stage for a successful quench.

Principle 2: Mastering the Controlled Quench

The goal of quenching is to cool the part fast enough to form the desired hard martensitic structure, but not so chaotically that it generates excessive stress.

Uniform Cooling with High-Pressure Gas

Modern vacuum furnaces use high-pressure gas quenching. After the soak, the hot workpiece is moved to a cooling chamber, which is rapidly filled with a high-pressure inert gas (like nitrogen, argon, or helium) that is circulated by a powerful fan.

The key is to achieve a uniform and sufficiently rapid extraction of heat from all surfaces. This ensures the transformation to martensite happens at roughly the same time throughout the part, minimizing transformation stress.

Key Quenching Variables

Process engineers have several levers to control the cooling rate:

- Gas Pressure: Higher pressure (e.g., 6, 10, or even 20 bar) increases the gas density, dramatically improving its ability to remove heat.

- Gas Velocity: A higher fan speed increases the flow of gas over the part, accelerating cooling.

- Gas Type: Helium has much higher thermal conductivity than nitrogen and provides the fastest quench rates, but it is significantly more expensive.

Understanding the Trade-offs

Achieving zero deformation is a balancing act, and every choice involves a trade-off.

Speed vs. Uniformity

An extremely fast quench rate is excellent for achieving maximum hardness, especially in lower-alloy steels. However, it also creates the most severe thermal shock and the highest risk of distortion. A slower quench is gentler on the part but may fail to achieve the required hardness if it doesn't exceed the steel's "critical cooling rate."

Part Geometry and Loading

Complex parts with both thick and thin sections are inherently prone to distortion. The thin sections will always cool faster than the thick ones. Proper orientation and racking of parts within the furnace are critical to ensure uniform exposure to both the heating elements and the quenching gas flow.

Cost vs. Capability

A vacuum furnace with high-pressure quenching (10+ bar) and variable fan speed offers the greatest process control but represents a significant capital investment. Using helium for ultra-fast quenching can be prohibitively expensive and is typically reserved for the most demanding applications.

Making the Right Choice for Your Goal

Your strategy should be tailored to the specific requirements of the workpiece.

- If your primary focus is maximum hardness in high-alloy tool steels: You need a rapid quench, so prioritize high gas pressure (6-20 bar) and high-velocity circulation.

- If your primary focus is minimal distortion in complex or thin parts: Prioritize uniformity over raw speed by using moderate gas pressure and potentially implementing an interrupted or multi-step quench to let temperatures equalize.

- If your primary focus is processing general-purpose parts cost-effectively: A nitrogen quench at 2-6 bar is a capable workhorse, but you must focus on optimizing soak times and part loading to promote uniformity.

Ultimately, preventing deformation in vacuum quenching is about controlling the rate and uniformity of temperature change across every stage of the process.

Summary Table:

| Element | Key Points |

|---|---|

| Uniform Heating | Use convection-assisted heating with inert gas (e.g., nitrogen) to avoid thermal gradients from radiative heating; ensure proper soaking for core temperature uniformity. |

| Controlled Quenching | Employ high-pressure gas quenching (e.g., 6-20 bar) with controlled variables like gas type, pressure, and velocity to minimize transformation stress and ensure uniform cooling. |

| Stress Management | Address thermal and transformation stresses through balanced heating and cooling rates; optimize part geometry and loading for reduced distortion. |

| Trade-offs | Balance quench speed vs. uniformity, part complexity vs. orientation, and cost vs. capability to tailor the process to specific goals like hardness or minimal distortion. |

Optimize your vacuum quenching processes with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, helping you achieve minimal deformation and superior results. Contact us today to discuss how we can enhance your heat treatment efficiency and outcomes!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability