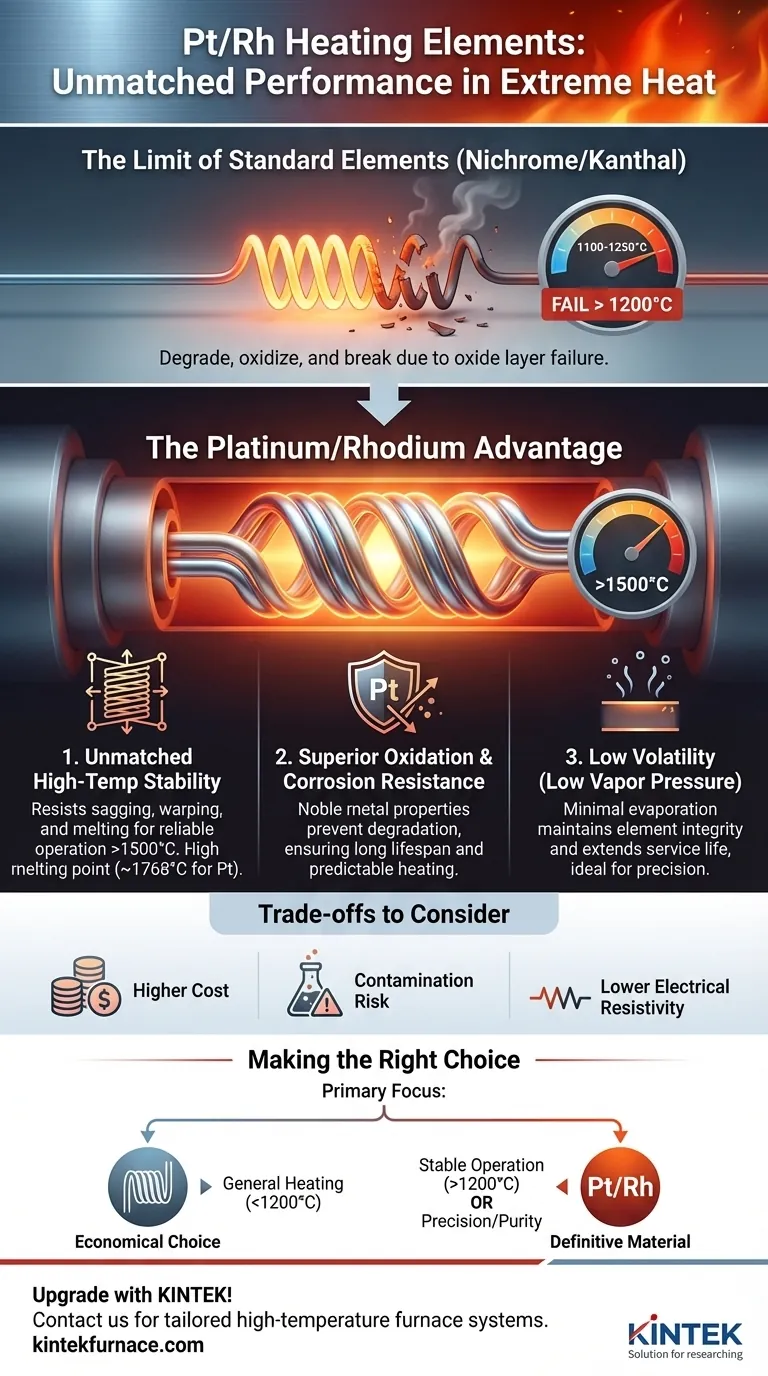

For applications demanding extreme heat, platinum/rhodium (Pt/Rh) alloys provide unmatched performance where more common materials fail. Their primary advantages are exceptional high-temperature stability, superior resistance to oxidation and corrosion, and very low volatility, ensuring a long and reliable operational life in the most challenging thermal environments.

While standard heating elements are suitable for many tasks, they begin to degrade, oxidize, and fail as temperatures exceed 1200°C. Platinum/rhodium alloys are engineered specifically for this extreme operational window, prioritizing long-term stability and performance over initial cost.

Why Standard Elements Have a Ceiling

To understand the value of platinum/rhodium, we must first recognize the limitations of more conventional heating element materials.

The Nichrome and Kanthal Limit

The most common resistance heating elements are made from alloys like Nichrome (nickel-chromium) or Kanthal (iron-chromium-aluminum).

These materials are workhorses in devices from toasters to industrial ovens. They function by forming a stable, protective oxide layer on their surface that prevents further degradation. However, this protection has its limits, typically around 1100-1250°C.

Failure at Extreme Temperatures

Above this threshold, the protective oxide layer can fail. The underlying metal begins to oxidize rapidly, thin out, and eventually break. This leads to element failure, process downtime, and costly repairs.

The Core Advantages of Platinum/Rhodium

Pt/Rh alloys are designed to overcome these limitations, making them essential for high-purity and ultra-high-temperature processes.

Unmatched High-Temperature Stability

Platinum has a very high melting point (~1768°C). The addition of rhodium further strengthens the alloy, increasing its mechanical strength and rigidity at extreme temperatures.

This means a Pt/Rh heating element will not sag, warp, or melt in applications where other metals would have already failed, providing stability in furnaces operating well above 1500°C.

Superior Oxidation and Corrosion Resistance

Unlike Nichrome, platinum is a noble metal. It has an intrinsic and exceptional resistance to oxidation, even when heated in air at very high temperatures.

This property ensures the element's diameter and electrical resistance remain remarkably stable over thousands of hours of use. This translates directly to a longer lifespan and highly predictable, repeatable heating processes.

Low Vapor Pressure (Low Volatility)

At extreme temperatures, all materials begin to evaporate, or "volatilize." This process thins the heating element over time, changing its resistance and eventually causing it to fail.

Pt/Rh alloys have a very low vapor pressure. They evaporate at a significantly slower rate than other metals at the same temperature, ensuring the element maintains its integrity for much longer.

Understanding the Trade-offs

The superior performance of platinum/rhodium comes with important considerations that are critical for proper material selection.

The Primary Factor: Cost

Platinum and rhodium are precious metals. As a result, Pt/Rh heating elements are substantially more expensive than their Nichrome or Kanthal counterparts. Their use is typically justified only when performance requirements make other materials unsuitable.

Susceptibility to Contamination

While highly resistant to oxidation, Pt/Rh alloys can be "poisoned" by certain contaminants at high temperatures.

Elements like silicon (from insulation), phosphorus, or sulfur can react with the platinum, forming low-melting-point compounds at the grain boundaries. This can cause the element to become brittle and fail prematurely. Careful furnace design and material selection are essential.

Lower Electrical Resistivity

Compared to Nichrome, Pt/Rh alloys have lower electrical resistivity. This is a key design parameter that means, for a given power output, the element may need to be longer or have a smaller cross-section. This directly impacts the physical design and winding of the furnace.

Making the Right Choice for Your Goal

Selecting the correct heating element material is a balance of performance needs and budget constraints.

- If your primary focus is general heating below 1200°C: More cost-effective alloys like Kanthal or Nichrome are the appropriate and economical choice.

- If your primary focus is stable operation above 1200°C: Platinum/rhodium is the definitive material for its unmatched thermal stability and long service life.

- If your primary focus is precision and process purity: The low volatility and inertness of Pt/Rh are essential for applications like semiconductor processing, crystal growth, or laboratory analysis.

Choosing the right material ensures your equipment operates reliably, efficiently, and with the precision your process demands.

Summary Table:

| Advantage | Description |

|---|---|

| High-Temperature Stability | Resists sagging, warping, and melting above 1500°C for reliable operation. |

| Oxidation and Corrosion Resistance | Noble metal properties prevent degradation, ensuring long lifespan and predictable heating. |

| Low Volatility | Minimal evaporation at high temperatures maintains element integrity and extends service life. |

| Ideal Applications | Best for processes above 1200°C, such as semiconductor processing and crystal growth. |

Upgrade your high-temperature processes with KINTEK's advanced heating solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnace systems, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, delivering unmatched reliability and efficiency. Contact us today to discuss how our platinum/rhodium alloy elements can enhance your lab's performance and longevity!

Visual Guide

Related Products

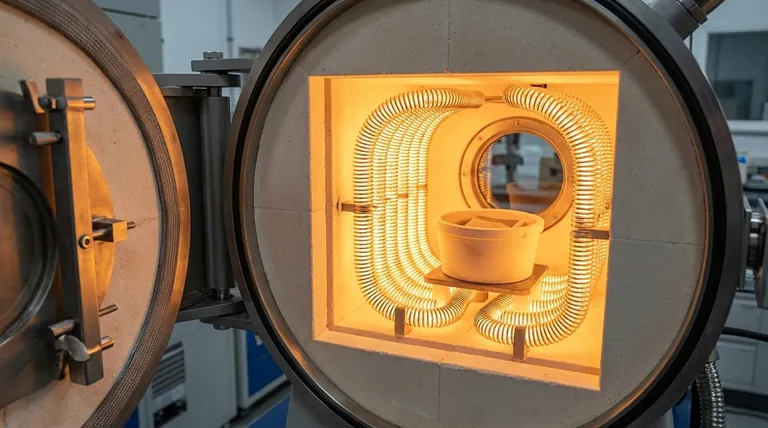

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment