In short, a vacuum sintering furnace provides a processing environment of unparalleled purity and control. By removing atmospheric gases, it prevents oxidation and contamination, which allows for the creation of cleaner, brighter, and denser final products with highly consistent and repeatable material properties.

The core advantage of a vacuum furnace is not merely the absence of air, but the active control it grants over the material's transformation. It removes an entire category of variables—atmospheric reactions and impurities—enabling a level of precision and quality that is often unattainable with other methods.

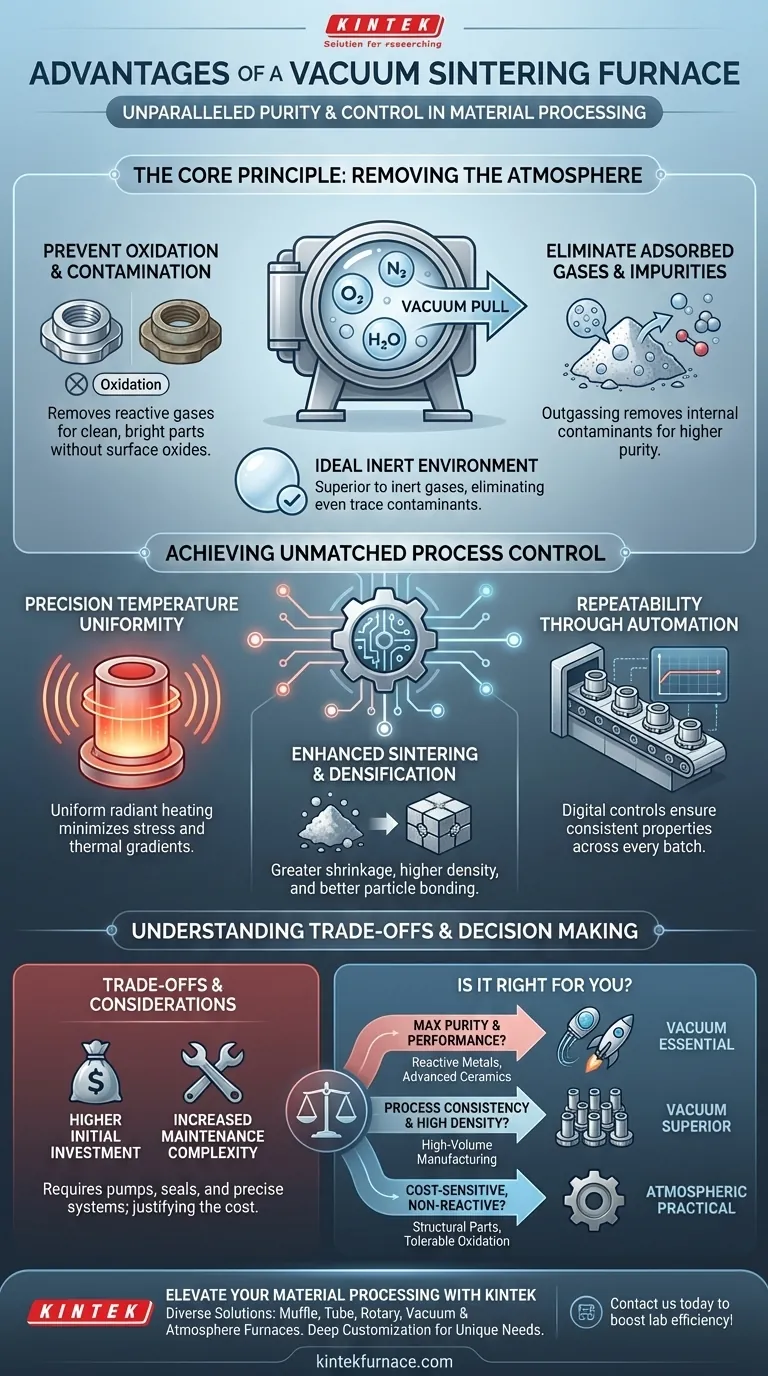

The Core Principle: Removing the Atmosphere

The "vacuum" in a vacuum furnace is its most defining feature. Creating this vacuum is not a passive step; it is an active process that fundamentally changes the sintering environment and unlocks several key benefits.

Preventing Oxidation and Contamination

In a traditional furnace, ambient air—rich with oxygen, nitrogen, and water vapor—reacts with the material at high temperatures. This causes oxidation and other unwanted chemical reactions, which can compromise the material's integrity and surface finish.

A vacuum furnace physically removes these reactive gases. This creates a contamination-free environment, resulting in clean, bright parts that don't require subsequent cleaning and are free from surface oxides.

Eliminating Adsorbed Gases and Impurities

The benefits go beyond preventing surface reactions. The vacuum actively pulls adsorbed gases and volatile impurities from within the powdered material itself.

This process, known as outgassing, removes contaminants that would otherwise be trapped during densification, leading to a final product with higher purity and fewer internal defects.

Creating an Ideal Inert Environment

While some processes use inert gases like argon to displace oxygen, a vacuum is often considered the most ideal inert atmosphere. Even high-purity bottled gases can contain trace amounts of contaminants.

A vacuum eliminates this risk, making it the superior choice for processing highly reactive materials or for applications demanding the absolute highest purity.

Achieving Unmatched Process Control

By removing the unpredictable variable of atmospheric gas, vacuum furnaces allow for an exceptional degree of control over the two most critical factors in sintering: temperature and material transformation.

Precision Temperature Uniformity

In the vacuum, heat transfer occurs primarily through radiation. This allows for extremely uniform heating across the entire part, minimizing the risk of hot spots or thermal gradients that can cause stress and defects.

Modern vacuum furnaces use advanced digital control systems to ensure this temperature is not only uniform but also precisely and repeatedly managed throughout the entire cycle.

Enhanced Sintering and Densification

The removal of trapped gases significantly aids in the final stage of sintering. Without internal gas pressure resisting compression, the material can achieve greater shrinkage and higher final density.

For liquid phase sintering, the clean, oxide-free surfaces of the powder particles also promote better wettability, leading to a stronger and more uniform bond.

Repeatability Through Automation

The combination of a controlled environment and precise digital management makes the vacuum sintering process highly repeatable.

Once a cycle is programmed, it can be executed identically time after time. This ensures that every part in a batch, and every batch over time, has the same consistent metallurgical properties.

Understanding the Trade-offs

While powerful, vacuum furnaces are a specialized technology with their own set of considerations. Objectivity requires acknowledging their limitations.

Higher Initial Investment

Vacuum furnaces, with their required pumps, seals, and control systems, represent a significant capital investment compared to conventional atmospheric furnaces. The cost must be justified by the need for high purity or performance.

Increased Maintenance Complexity

Maintaining a hard vacuum requires a system of robust pumps, high-integrity seals, and precise instrumentation. This adds a layer of maintenance complexity and cost that is not present with simpler furnace designs.

Not a Universal Solution

For many non-reactive materials or applications where minor oxidation is acceptable, the benefits of a vacuum may not outweigh the added cost and complexity. A traditional atmospheric furnace is often a more practical and cost-effective choice for these scenarios.

Is a Vacuum Furnace Right for Your Application?

Choosing the right furnace technology depends entirely on your material requirements and production goals.

- If your primary focus is maximum purity and performance: Vacuum sintering is essential for reactive metals (like titanium), advanced ceramics, medical implants, and electronic components where any contamination degrades properties.

- If your primary focus is process consistency and high density: Vacuum is the superior choice for high-volume manufacturing where minimal batch-to-batch variation and maximum strength are critical.

- If your primary focus is cost-sensitive, non-reactive components: A conventional atmospheric furnace is likely the more practical and economical solution for materials like iron-based structural parts where some surface oxidation is tolerable.

Ultimately, investing in vacuum technology is a decision to prioritize control and purity above all else.

Summary Table:

| Advantage | Description |

|---|---|

| Prevents Oxidation and Contamination | Removes reactive gases for clean, bright parts without surface oxides. |

| Eliminates Adsorbed Gases and Impurities | Outgassing removes internal contaminants, increasing purity and reducing defects. |

| Ensures Precision Temperature Uniformity | Radiation-based heating provides uniform heat distribution, minimizing stress. |

| Enhances Sintering and Densification | Promotes greater shrinkage and higher density with better particle bonding. |

| Offers High Repeatability Through Automation | Digital controls ensure consistent metallurgical properties across batches. |

Ready to elevate your material processing with precision and purity? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're working with reactive metals, advanced ceramics, or need high-density results, our vacuum sintering furnaces deliver unmatched control and consistency. Contact us today to discuss how we can tailor a solution for your specific needs and boost your lab's efficiency!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering