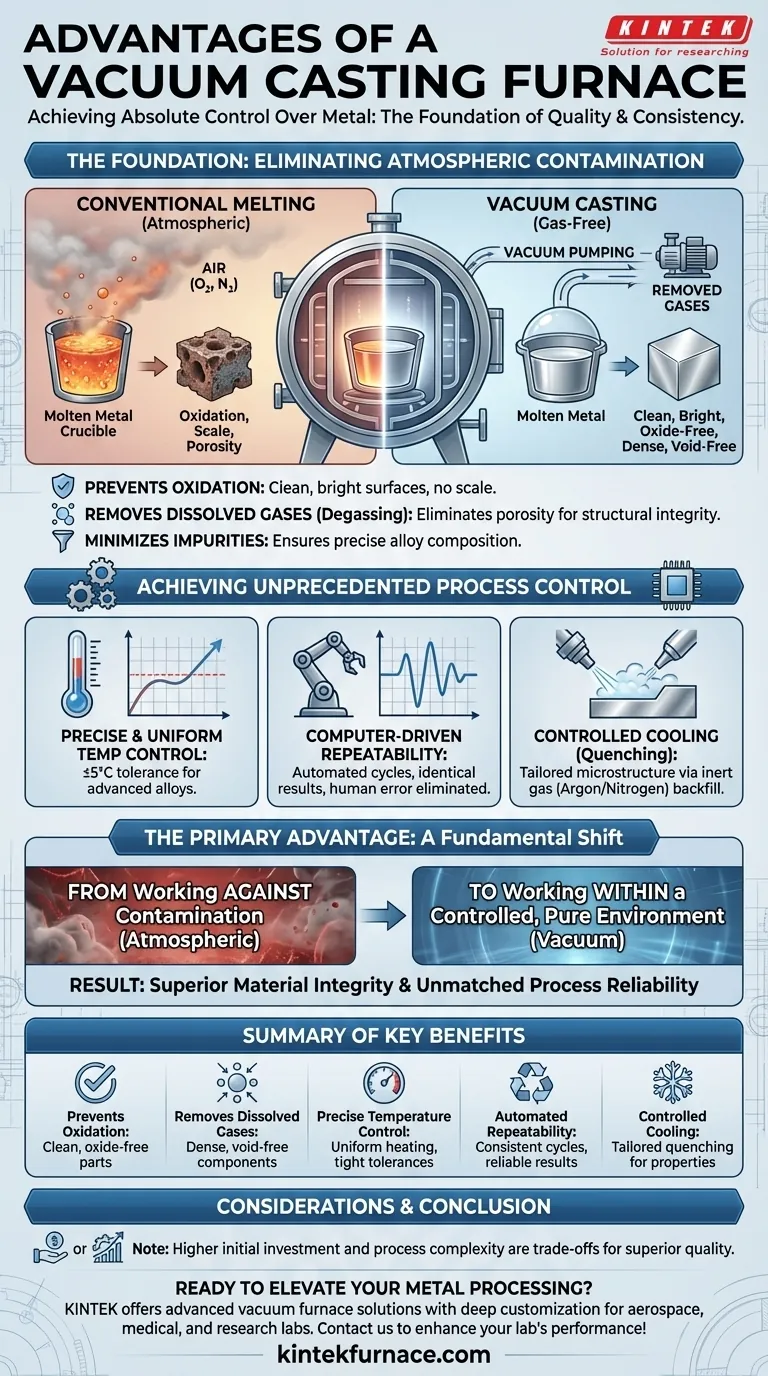

At its core, a vacuum casting furnace is about achieving absolute control over the metal. It provides a suite of advantages that fundamentally solve quality and consistency issues by creating a pristine, gas-free environment. Key benefits include the complete prevention of oxidation, the removal of dissolved gases that cause porosity, and the ability to execute highly precise, repeatable heating and cooling cycles.

The primary advantage of a vacuum furnace is not just incremental improvement. It is a fundamental shift from working against atmospheric contamination to working within a controlled, pure environment, resulting in superior material integrity and unmatched process reliability.

The Foundation: Eliminating Atmospheric Contamination

The most significant benefit of vacuum casting stems from what it removes: the atmosphere. Air, with its reactive oxygen and nitrogen, is the primary source of contamination in conventional melting and casting processes.

Preventing Oxidation and Discoloration

In a normal atmosphere, hot metal surfaces instantly react with oxygen to form oxides. This results in discoloration, scale, and a compromised surface finish that often requires secondary cleaning.

A vacuum furnace removes virtually all oxygen before heating begins. This ensures parts emerge from the furnace clean, bright, and free of oxides, preserving the integrity of the alloy and reducing post-processing labor.

Removing Dissolved Gases (Degassing)

Molten metal readily absorbs atmospheric gases like hydrogen and nitrogen. As the metal cools and solidifies, these gases are forced out of solution, creating microscopic bubbles that result in porosity.

The vacuum actively pulls these trapped gases out of the molten metal before casting. This degassing effect is critical for creating dense, void-free parts with superior structural integrity, hardness, and fatigue resistance.

Minimizing Impurities

Beyond oxygen, the atmosphere contains moisture and other airborne contaminants. A vacuum environment is an inherently clean environment that prevents these impurities from being introduced into the melt, ensuring the final product matches the alloy's intended chemical composition.

Achieving Unprecedented Process Control

A vacuum furnace is more than just a sealed box; it is a precision instrument. The controlled environment allows for a level of process management that is impossible to achieve in an open-air system.

Precise and Uniform Temperature Control

Radiant heat transfer is extremely efficient and uniform in a vacuum. This allows the furnace to maintain incredibly precise and even temperatures, typically within a very small tolerance range (e.g., ±5°C).

This level of control is essential for processing advanced alloys and superalloys that have very narrow processing windows.

Computer-Driven Repeatability

Modern vacuum furnaces are fully automated. The heating rates, holding times, temperature setpoints, and cooling profiles are managed by a computer.

This automation eliminates human variability and guarantees that every production cycle is identical. For industries like aerospace and medical, this metallurgical repeatability is not a luxury—it is a requirement.

Controlled Cooling (Quenching)

Many vacuum furnaces integrate rapid cooling or quenching systems. By backfilling the chamber with an inert gas like argon or nitrogen, the system can cool the part at a precisely controlled rate. This is vital for achieving the specific microstructure, hardness, and other mechanical properties required by the design.

Understanding the Trade-offs

While powerful, a vacuum furnace is not the universal solution for every application. Objectivity requires acknowledging its specific considerations.

Higher Initial Investment

Vacuum furnaces, with their robust chambers, pumping systems, and advanced controls, represent a significantly higher capital expenditure compared to conventional atmospheric furnaces.

Increased Process Complexity

Operating and maintaining a vacuum system requires specialized knowledge. Managing vacuum pumps, checking seals for leaks, and understanding the control systems adds a layer of operational complexity.

Potentially Longer Cycle Times

While heating can be very efficient, the process of pumping the chamber down to the required vacuum level adds time to the beginning of each cycle. This can make it less suitable for high-volume, low-margin production where cycle time is the primary driver.

Is a Vacuum Furnace Right for Your Application?

The decision to use a vacuum furnace should be driven by the technical requirements of your final product and the materials you are working with.

- If your primary focus is producing parts from reactive alloys (like titanium, nickel superalloys, or zirconium): A vacuum furnace is non-negotiable to prevent catastrophic contamination from oxygen and nitrogen.

- If your primary focus is achieving maximum part density and eliminating all porosity: The degassing capability of a vacuum furnace is the most effective technology for producing structurally sound, void-free components.

- If your primary focus is meeting stringent quality standards for aerospace or medical applications: The precise, computer-driven repeatability of a vacuum furnace is essential for certification and reliability.

- If your primary focus is high-volume casting of simple, non-reactive metals (like standard aluminum or bronze): A traditional atmospheric furnace may be the more cost-effective choice if extreme purity is not a requirement.

Ultimately, choosing a vacuum furnace is an investment in process control and the intrinsic quality of the material itself.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Prevents Oxidation | Eliminates oxygen for clean, oxide-free parts |

| Removes Dissolved Gases | Reduces porosity for dense, void-free components |

| Precise Temperature Control | Maintains uniform heating within tight tolerances |

| Automated Repeatability | Ensures consistent cycles for reliable results |

| Controlled Cooling | Allows tailored quenching for specific properties |

Ready to elevate your metal processing with advanced vacuum furnace solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, delivering superior purity, precision, and reliability for industries like aerospace and medical. Contact us today to discuss how we can enhance your lab's performance!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Induction Melting Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing