At its core, gas quenching offers superior process control and part quality compared to traditional liquid-based methods. By using gases like nitrogen or argon under high pressure, this technique provides a more uniform, less severe quench that significantly reduces part distortion, eliminates messy residues, and allows for highly repeatable, finely-tuned cooling cycles.

The fundamental shift from liquid to gas quenching is moving from a brute-force cooling method to a precision engineering process. While traditional methods are effective, gas quenching provides unparalleled control over the final properties and dimensions of a heat-treated component.

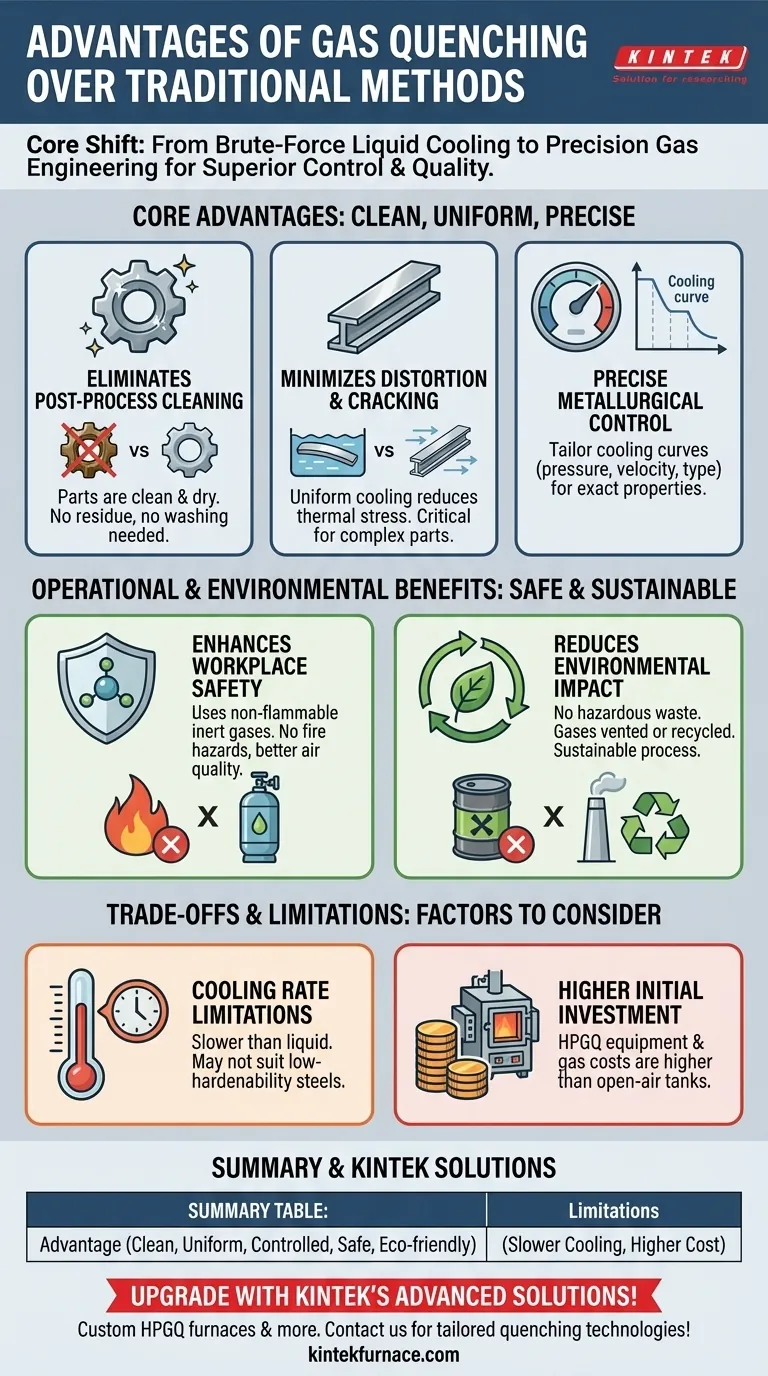

The Core Advantages of Gas Quenching

Gas quenching’s benefits stem from the inherent physical properties of gas compared to liquids. This translates into tangible improvements in part quality, process consistency, and operational efficiency.

Eliminating Post-Process Cleaning

With traditional oil or polymer quenching, a residual film is left on the part's surface. This residue must be cleaned off in a separate, time-consuming step, adding labor and material costs to the overall process.

Gas quenching uses inert, high-purity gases. This leaves parts perfectly clean and dry, ready for the next manufacturing step without any need for washing or degreasing.

Minimizing Part Distortion and Cracking

Liquid quenching subjects a part to intense and often non-uniform thermal shock. The rapid, boiling heat transfer can create massive temperature gradients within the material, leading to internal stresses that cause warping, distortion, or even cracking.

Gas, by contrast, provides a much more uniform cooling environment. It removes heat more gently and evenly from all surfaces of the part, drastically reducing thermal stress and preserving the component's dimensional accuracy. This is a critical advantage for complex geometries or thin-walled parts.

Achieving Precise Metallurgical Control

The cooling rate of a liquid quench is largely fixed and difficult to modify. This "one-size-fits-all" approach may not be optimal for achieving specific microstructures in advanced alloys.

Gas quenching offers variable cooling control. By adjusting gas pressure, velocity, and type, operators can precisely tailor the cooling curve to meet the exact metallurgical requirements of the material, ensuring desired hardness and mechanical properties with high repeatability.

Operational and Environmental Benefits

Beyond part quality, switching to gas quenching has significant positive impacts on the safety and sustainability of a heat treatment operation.

Enhancing Workplace Safety

Oil quenching involves heating large volumes of flammable oil, creating fire hazards and exposing workers to smoke and vapors.

Gas quenching is inherently safer. It uses non-flammable, inert gases like nitrogen, helium, or argon, eliminating the risk of fire and improving air quality in the facility.

Reducing Environmental Impact

Used quench oils and polymers must be treated as hazardous waste, leading to significant disposal costs and environmental liability.

Gas quenching is an environmentally clean process. The gases are either vented to the atmosphere (if nitrogen) or can be recycled, completely eliminating liquid waste streams and their associated regulatory burdens.

Understanding the Trade-offs and Limitations

While powerful, gas quenching is not a universal solution. Its primary limitation is directly tied to its key advantage: its less severe cooling action.

Cooling Rate Limitations

Even at very high pressures (20 bar or more), gas cannot remove heat as rapidly as agitated oil or water. This is a critical factor for certain materials.

Low-hardenability steels, for example, require extremely fast cooling rates to transform into the desired hard martensitic structure. For these specific alloys, the slower cooling of a gas quench may be insufficient, making a traditional liquid quench necessary.

Higher Initial Investment

The equipment required for high-pressure gas quenching (HPGQ), typically integrated into a vacuum furnace, represents a higher capital investment than a simple open-air oil quench tank. The ongoing cost of purchasing high-purity gases must also be factored into the operational budget.

Making the Right Choice for Your Goal

The decision between gas and liquid quenching depends entirely on your material, part complexity, and production priorities.

- If your primary focus is high dimensional accuracy and minimal distortion: Gas quenching is the superior choice, especially for complex, high-value components made from air-hardening tool steels or specialty alloys.

- If your primary focus is processing low-hardenability alloys at the lowest cost: Traditional oil quenching remains a viable and effective method, provided you can manage the associated distortion and cleaning requirements.

- If your primary focus is process cleanliness, safety, and environmental compliance: Gas quenching is the undisputed leader, offering a modern, sustainable, and operator-friendly solution.

Ultimately, adopting gas quenching is an investment in process control, consistency, and quality.

Summary Table:

| Advantage | Description |

|---|---|

| Eliminates Post-Process Cleaning | Parts come out clean and dry, no residue from gases like nitrogen or argon. |

| Minimizes Part Distortion and Cracking | Uniform cooling reduces thermal stress, preserving dimensional accuracy. |

| Achieves Precise Metallurgical Control | Adjustable cooling rates for specific material properties and repeatability. |

| Enhances Workplace Safety | Uses non-flammable, inert gases, reducing fire hazards and improving air quality. |

| Reduces Environmental Impact | No hazardous waste; gases can be vented or recycled, cutting disposal costs. |

| Limitations | Slower cooling rates may not suit low-hardenability steels; higher initial investment. |

Upgrade your heat treatment process with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing efficiency and quality. Contact us today to discuss how our tailored gas quenching technologies can benefit your operations!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why might a vacuum furnace maintain vacuum during cooling? Protect Workpieces from Oxidation and Control Metallurgy

- Why are vacuum furnaces considered important in various industries? Unlock Superior Material Performance

- Why are some vacuum furnaces backfilled with a partial pressure gas? Prevent Alloy Depletion in High-Temp Processes

- What is the role of the temperature control system in a vacuum furnace? Achieve Precise Material Transformations

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance