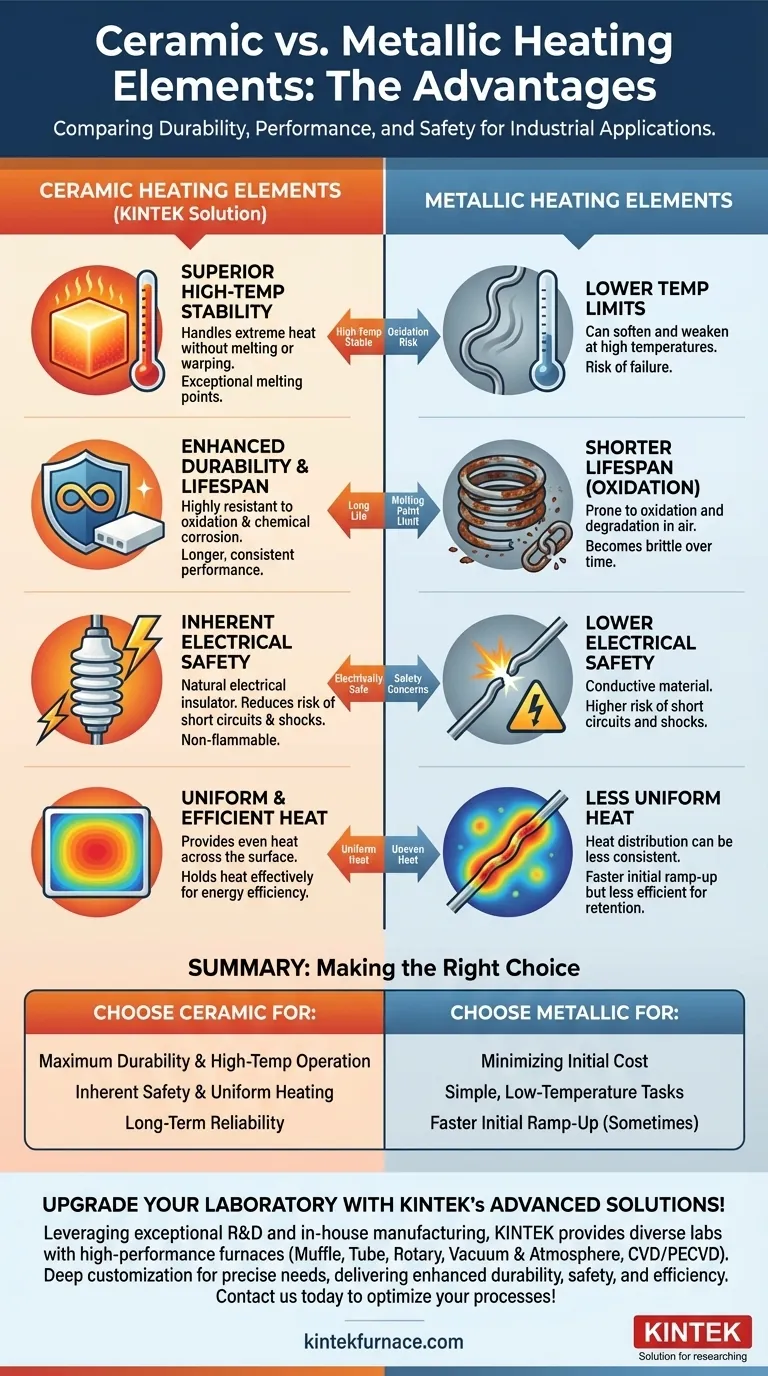

When choosing a heating element, the advantages of ceramic technology primarily revolve around superior durability, higher operational temperatures, and enhanced safety. Unlike their metallic counterparts, ceramic elements are highly resistant to oxidation and corrosion, leading to a significantly longer service life and more consistent performance over time.

The decision between ceramic and metallic heating elements is not about which is universally superior, but about aligning the element's fundamental material properties with the specific demands of your application. Ceramic excels where high heat, longevity, and safety are paramount.

The Core Differences: Material Science at Work

The distinct advantages of ceramic heaters are not arbitrary; they are direct results of their fundamental material composition compared to traditional metals.

Superior High-Temperature Stability

Ceramic materials possess exceptionally high melting points. This allows them to operate at extreme temperatures without melting, warping, or deforming under thermal stress.

Metallic elements, in contrast, can soften and weaken as they approach their thermal limits, leading to potential failure.

Enhanced Durability and Lifespan

The primary factor limiting a metallic heater's life is oxidation. When heated in the presence of air, metals corrode and degrade, becoming brittle and less effective over time.

Ceramic elements are inert and highly resistant to oxidation and chemical corrosion. This immunity to degradation ensures they do not wear out quickly, providing a much longer and more reliable operational lifespan.

Inherent Electrical Safety

Ceramic is a natural electrical insulator. This property is a significant safety advantage, as it inherently prevents the flow of electricity to the element's exterior, drastically reducing the risk of short circuits and electrical shock.

Furthermore, their non-flammable nature minimizes the risk of fire, enhancing overall operational safety in both industrial and household applications.

Uniform and Efficient Heat Transfer

Ceramic elements are known for providing very uniform heat distribution across their entire surface. This consistency is critical for applications requiring precise and even heating.

They also hold heat effectively, meaning they require less energy to maintain a target temperature once it's reached. This thermal retention can lead to greater energy efficiency in many systems.

Understanding the Trade-offs

While ceramic offers compelling benefits, a balanced assessment requires acknowledging its trade-offs. No technology is the perfect solution for every scenario.

Initial Cost

Manufacturing advanced ceramic components is often more complex and costly than producing simple metallic wire elements like nichrome. For applications where low upfront cost is the primary driver, a metallic heater may be the more economical choice.

Brittleness and Physical Shock

While exceptionally durable against heat and corrosion, ceramic materials can be more brittle than ductile metals. They may be more susceptible to cracking or fracturing if subjected to significant physical impact or mechanical shock.

Thermal Ramp-Up Speed

In some cases, simple metallic wire elements can have a faster initial heat-up time from a cold start due to their lower thermal mass. However, once at temperature, ceramic's heat retention often proves more efficient for cyclic operations.

Making the Right Choice for Your Goal

Your application's priorities should guide your selection. Use this framework to make a clear decision between ceramic and metallic heating technologies.

- If your primary focus is maximum durability and high-temperature operation: Ceramic is the definitive choice for its resistance to oxidation and structural integrity under extreme heat.

- If your primary focus is inherent safety and uniform heating: Ceramic's electrical insulation and even heat distribution make it ideal for consumer appliances and sensitive processes.

- If your primary focus is minimizing initial cost for a simple, low-temperature task: A traditional metallic element often provides the most straightforward and budget-friendly solution.

By understanding these fundamental material differences, you can select the heating technology that delivers the precise performance, safety, and longevity your project demands.

Summary Table:

| Feature | Ceramic Heating Elements | Metallic Heating Elements |

|---|---|---|

| Max Operating Temperature | High (superior stability) | Lower (may soften) |

| Lifespan | Long (resistant to oxidation) | Shorter (prone to corrosion) |

| Safety | High (electrical insulator, non-flammable) | Lower (risk of short circuits) |

| Heat Distribution | Uniform and efficient | Less uniform |

| Initial Cost | Higher | Lower |

| Durability to Physical Shock | Brittle (susceptible to cracking) | More ductile (resistant to impact) |

Upgrade your laboratory with KINTEK's advanced heating solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with high-performance furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization capability ensures precise alignment with your unique experimental needs, delivering enhanced durability, safety, and efficiency. Contact us today to discuss how our ceramic heating technologies can optimize your processes and achieve superior results!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights