In essence, a muffle furnace excels at providing a highly controlled, uniform heating environment that protects samples from contamination. Its primary advantages are this precision and purity. However, these benefits come at the cost of lower heating efficiency and slower processing cycles compared to less specialized ovens.

The core decision to use a muffle furnace is a trade-off. You are choosing unparalleled process purity and temperature uniformity in exchange for higher energy consumption and longer cycle times, making it a specialized tool for when precision is non-negotiable.

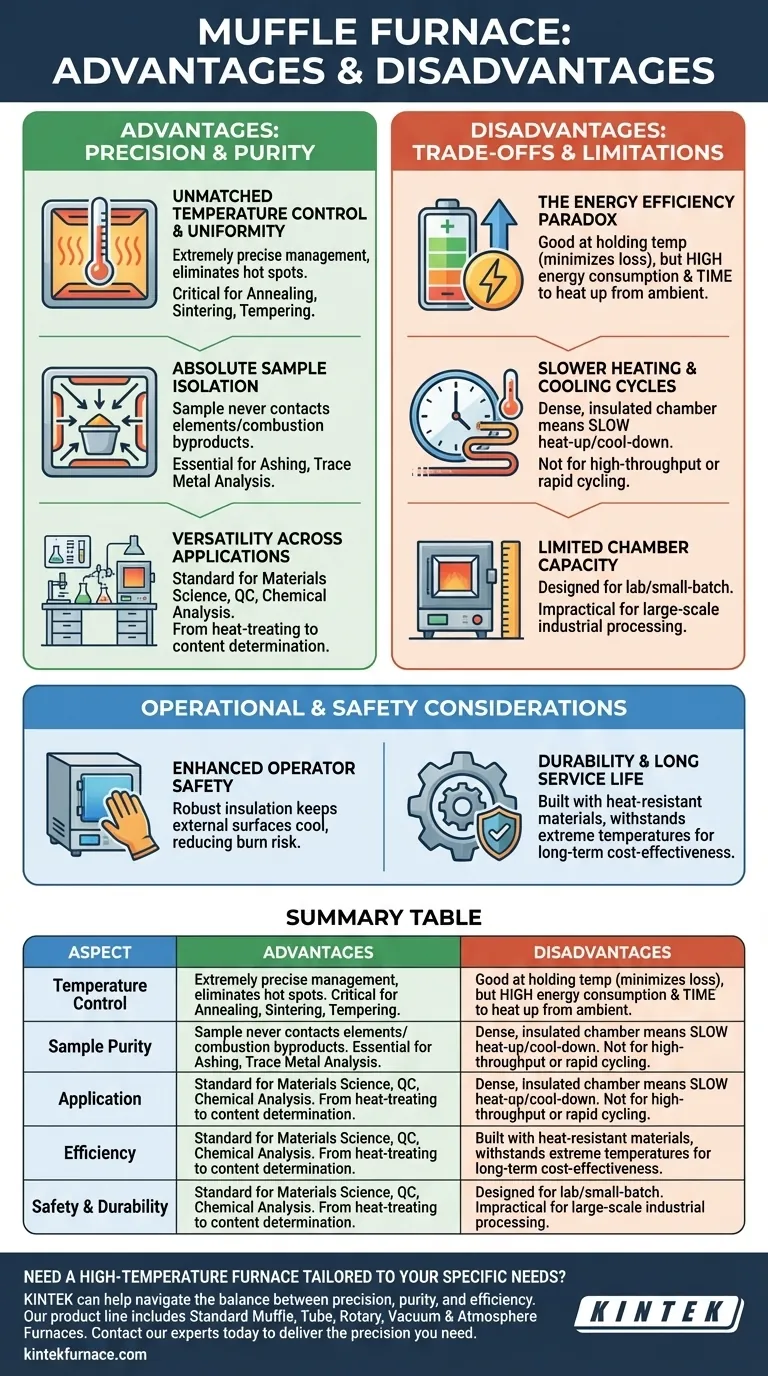

The Core Advantages: Precision and Purity

A muffle furnace's design directly enables its most significant benefits. The term "muffle" refers to the insulated inner chamber that separates the material being heated from the actual heating elements.

Unmatched Temperature Control and Uniformity

The insulated chamber and modern digital controllers allow for extremely precise temperature management.

This design ensures uniform heat distribution throughout the chamber, eliminating hot spots. Processes like annealing, sintering, and tempering depend on this consistency for reliable and repeatable results.

Absolute Sample Isolation

The defining feature is that the sample never comes into contact with the heating elements or any byproducts of combustion (in fuel-fired models).

This isolation is critical for applications like ashing or trace metal analysis, where even minor contamination from a heating element could compromise the entire experiment.

Versatility Across Applications

Because of their precision and purity, muffle furnaces are indispensable in many fields.

They are standard equipment in materials science labs, quality control departments, chemical analysis facilities, and research institutions for tasks ranging from heat-treating steel to determining the non-combustible content of a sample.

Understanding the Trade-offs and Limitations

While powerful, a muffle furnace is not the optimal tool for every heating task. Understanding its inherent limitations is key to using it effectively.

The Energy Efficiency Paradox

Muffle furnaces are often called "energy efficient" due to their thick insulation, which minimizes heat loss when holding a stable temperature.

However, they can also be considered to have low heating efficiency and high energy consumption. This is because heating the dense, well-insulated chamber from ambient temperature requires a significant amount of initial energy and time.

Slower Heating and Cooling Cycles

The same thermal mass and heavy insulation that ensure temperature stability also mean the furnace heats up and cools down slowly.

This characteristic makes it unsuitable for high-throughput applications where rapid cycling is required. Other types of lab ovens are better suited for such tasks.

Limited Chamber Capacity

Most muffle furnaces are designed for laboratory or small-batch production. Their size is inherently limited, making them impractical for large-scale industrial processing.

Operational and Safety Considerations

Beyond performance, the physical design of a muffle furnace offers tangible benefits for operators.

Enhanced Operator Safety

The robust insulation and sealed chamber design mean that the external surfaces of the furnace remain relatively cool, reducing the risk of burns and creating a safer working environment.

Durability and Long Service Life

These furnaces are built from durable, heat-resistant materials designed to withstand extreme temperatures for extended periods. With proper maintenance, they offer a very long service life, which contributes to their long-term cost-effectiveness.

How to Apply This to Your Project

Your choice depends entirely on what you value most in your thermal process.

- If your primary focus is analytical purity: The muffle furnace is the correct choice, as its isolated chamber is essential for preventing contamination in processes like ashing or gravimetric analysis.

- If your primary focus is material property development: Its superior temperature uniformity makes it ideal for heat treatments like annealing, sintering, or hardening where consistent results are critical.

- If your primary focus is speed and high throughput: A muffle furnace is likely the wrong tool; consider a convection or vacuum oven designed for faster cycle times.

Ultimately, a muffle furnace is a specialist's instrument, chosen when the integrity of the process justifies the cost in energy and time.

Summary Table:

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Temperature Control | Unmatched precision and uniformity | Slower heating and cooling cycles |

| Sample Purity | Absolute isolation prevents contamination | Not suitable for high-throughput tasks |

| Application | Versatile for critical lab processes (e.g., ashing, annealing) | Limited chamber capacity for large-scale use |

| Efficiency | Excellent heat retention at stable temperatures | High initial energy consumption to heat up |

| Safety & Durability | Cool external surfaces; long service life | Higher operational cost due to energy use |

Need a High-Temperature Furnace Tailored to Your Specific Needs?

Choosing the right furnace is critical for your lab's success. The balance between precision, purity, and efficiency is unique to every application.

KINTEK can help you navigate this decision. We leverage our exceptional R&D and in-house manufacturing to provide advanced solutions. Whether you need a standard Muffle Furnace or a highly customized system, our product line—including Tube Furnaces, Rotary Furnaces, and Vacuum & Atmosphere Furnaces—is designed to meet your exact experimental requirements.

Let us provide you with a furnace that delivers the precision you need without compromising on your operational goals.

Contact our experts today to discuss your project and discover the perfect high-temperature solution for your laboratory.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation