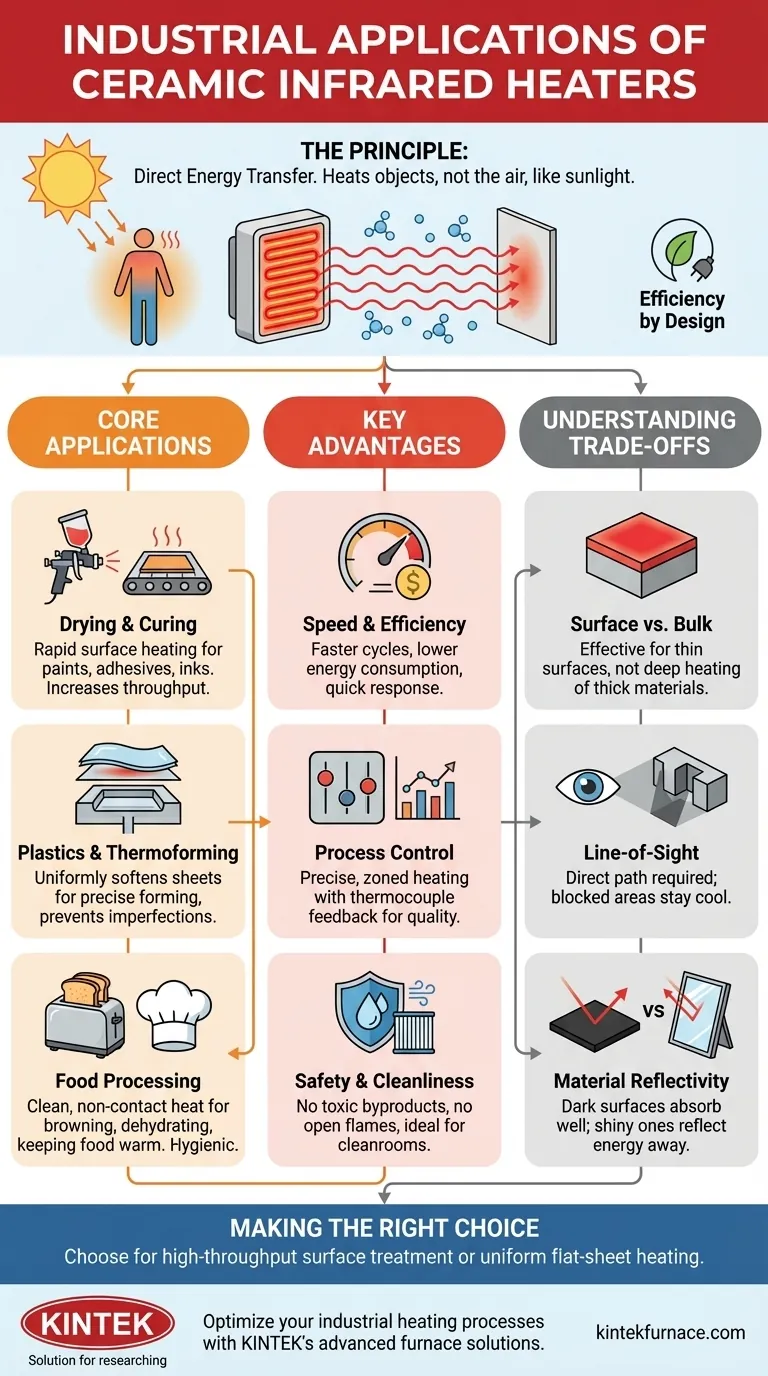

In industrial settings, ceramic infrared (IR) heaters are most commonly used for processes like drying and curing paints or adhesives, thermoforming plastic sheets, and certain food processing applications. They are valued for their ability to deliver precise, non-contact heat efficiently to a product's surface without heating the surrounding air, making them a clean and rapid heating solution.

The true value of ceramic infrared heaters isn't just the heat they produce, but the way they deliver it. Their effectiveness stems from the direct transfer of radiant energy, which heats objects, not the air, leading to significant gains in speed and process control for surface-focused applications.

The Principle: Why Infrared is Different

Direct Energy Transfer

Unlike convection ovens that heat the air to warm a product, infrared heaters emit electromagnetic waves. These waves travel unimpeded through the air and are absorbed directly by the target material, converting into heat.

Think of it like the sun warming the earth on a cool day. The air can be crisp, but the direct sunlight feels warm on your skin because you are absorbing the radiant energy.

Efficiency by Design

Because IR heaters heat the product directly, very little energy is wasted warming up large volumes of air or the entire oven structure. This makes them exceptionally energy-efficient for the right kind of job.

Core Industrial Applications in Detail

Drying and Curing Processes

This is one of the most common uses for ceramic IR heaters. They are ideal for driving moisture or solvents from thin surface layers, such as in paint drying tunnels, adhesive curing, or drying printed inks on paper and textiles.

The rapid surface heating accelerates the evaporation process significantly faster than hot air alone, increasing throughput on a production line.

Plastics and Thermoforming

Ceramic IR heaters are a cornerstone of the plastics industry, particularly in thermoforming. Large arrays of heaters are used to soften plastic sheets uniformly until they are pliable.

Once the sheet reaches the correct temperature, it is stretched over a mold using a vacuum. The ability to create precisely controlled heat zones with multiple heaters ensures the plastic heats evenly, preventing weak spots or imperfections in the final product.

Food Processing

The clean, non-contact nature of IR heat is highly beneficial in food production. Applications include browning baked goods, dehydrating fruits and vegetables, melting cheese toppings, or keeping food warm in commercial serving lines.

Because there is no forced air, this method of heating doesn't kick up dust or contaminants, preserving the hygienic integrity of the food product.

Understanding the Key Advantages

Efficiency and Speed

The direct heating principle means ceramic IR heaters have a very high heat-up and cool-down response. This translates directly to shorter production cycles and lower energy consumption compared to traditional convection systems.

Process Control and Quality

Ceramic heaters can be configured in large, zoned arrays. By integrating them with thermocouples for temperature feedback, operators can achieve incredibly precise control over the heating process.

This level of control is critical for ensuring product quality and repeatability, especially when working with temperature-sensitive materials.

Safety and Cleanliness

These heaters produce no toxic byproducts and have no open flames. Because they don't use fans or blowers, they are ideal for cleanroom environments or processes where airborne particulates would cause defects, such as in high-quality coating applications.

Understanding the Trade-offs

Surface vs. Bulk Heating

Infrared radiation is primarily a surface phenomenon. It is excellent for heating thin materials or the surface of an object, but it is not effective for heating the entire volume of a thick or non-conductive product.

Line-of-Sight Requirement

For an object to be heated, it must have a direct, unobstructed line of sight to the heater. Any shadows or blocked areas will remain cool. This makes IR a poor choice for heating complex, three-dimensional parts with many internal features.

Material Color and Reflectivity

The effectiveness of an IR heater depends on the target material's ability to absorb infrared energy. Dark, matte surfaces absorb heat very well, while light-colored or shiny, reflective surfaces (like polished aluminum) will reflect most of the energy away, making them difficult to heat with IR alone.

Making the Right Choice for Your Process

Deciding on the right heating technology requires matching its strengths to your specific goal.

- If your primary focus is high-throughput surface treatment (like drying paint or curing adhesive): Ceramic IR heaters are an excellent choice due to their speed and efficiency.

- If your primary focus is uniformly heating a large, flat sheet (like in thermoforming): The ability to create zoned arrays makes ceramic IR an industry standard for this task.

- If your primary focus is heating a bulk material or a complex 3D part: A convection oven or another heating method may be a more suitable solution due to IR's line-of-sight limitations.

Ultimately, understanding how ceramic infrared heaters work is the key to deploying them effectively for faster, cleaner, and more efficient industrial processes.

Summary Table:

| Application | Key Benefits |

|---|---|

| Drying and Curing | Rapid surface heating, high throughput, energy-efficient |

| Plastics and Thermoforming | Uniform heating, precise control, prevents imperfections |

| Food Processing | Clean, non-contact heat, hygienic, no contaminants |

| General Advantages | Fast heat-up/cool-down, no toxic byproducts, ideal for cleanrooms |

Ready to optimize your industrial heating processes? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities. Whether you're in drying, thermoforming, or food processing, we can design a solution to precisely meet your unique experimental and production requirements. Contact us today to discuss how our expertise can enhance your efficiency and quality!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance

- What heating elements are used in high-temperature tube furnaces? Discover SiC and MoSi2 for Extreme Heat

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C

- What is the operating temperature of SiC? Unlock Reliable Performance Up to 1600°C