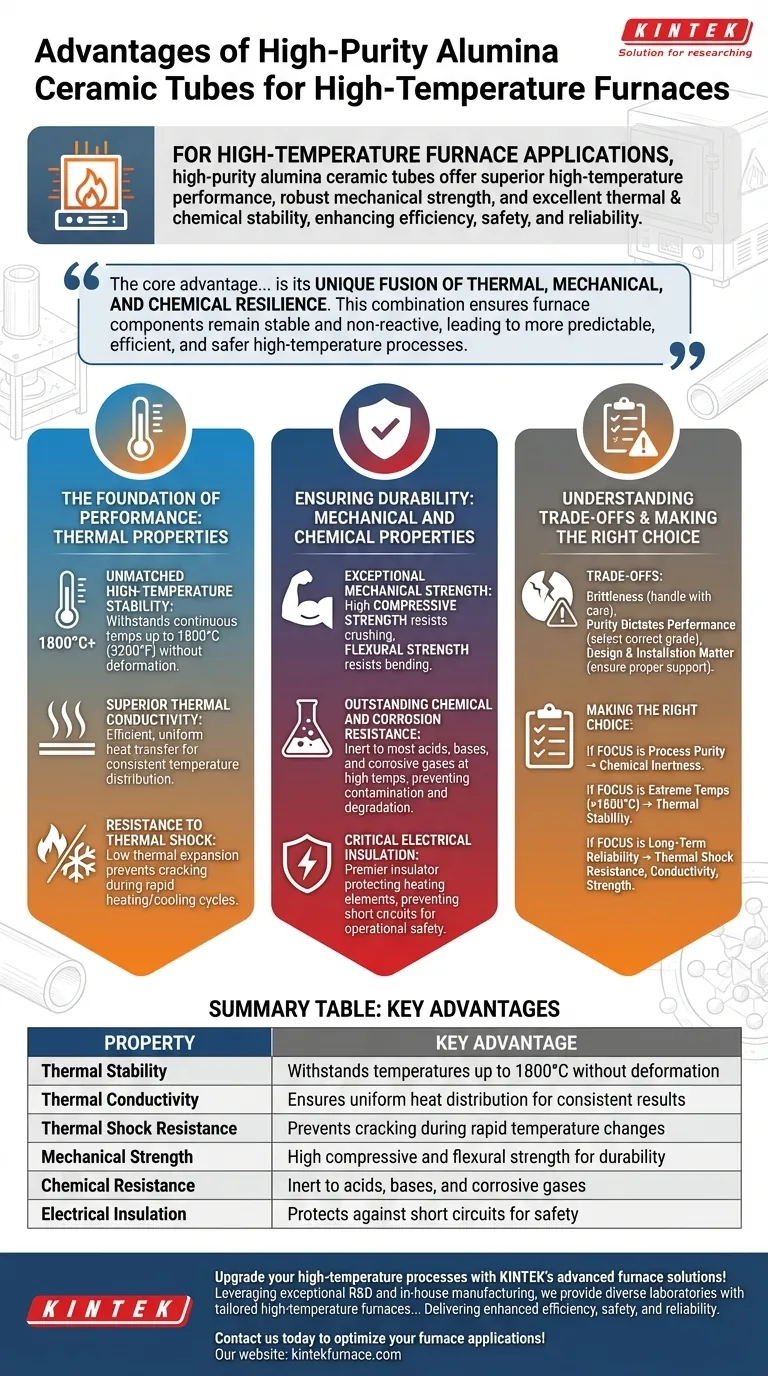

For high-temperature furnace applications, high-purity alumina ceramic tubes offer a distinct combination of superior high-temperature performance, robust mechanical strength, and excellent thermal and chemical stability. These properties allow them to enhance production efficiency, improve safety, and ensure reliable operation in the most demanding industrial environments.

The core advantage of high-purity alumina is not a single attribute, but its unique fusion of thermal, mechanical, and chemical resilience. This combination ensures that furnace components remain stable and non-reactive, leading to more predictable, efficient, and safer high-temperature processes.

The Foundation of Performance: Thermal Properties

The primary role of a furnace tube is to perform reliably under extreme heat. Alumina's thermal characteristics are the bedrock of its suitability for this task.

Unmatched High-Temperature Stability

High-purity alumina can withstand continuous operating temperatures up to 1800°C (over 3200°F). This ensures the tube maintains its structural integrity without softening, deforming, or failing at the extreme temperatures required for sintering, melting, and chemical synthesis.

Superior Thermal Conductivity

Alumina possesses good thermal conductivity for a ceramic. This property allows for efficient and uniform heat transfer from the heating elements to the process environment, ensuring consistent temperature distribution throughout the furnace chamber.

Resistance to Thermal Shock

Furnaces often undergo rapid heating and cooling cycles. Alumina's low thermal expansion and inherent stability give it excellent resistance to thermal shock, preventing cracking and failure that can occur when materials expand and contract too quickly.

Ensuring Durability: Mechanical and Chemical Properties

Beyond heat, a furnace tube must endure mechanical stress and potentially corrosive environments. Alumina's composition provides exceptional durability.

Exceptional Mechanical Strength

Alumina is a very hard and strong material. Its high compressive strength resists crushing forces, while its flexural strength resists bending. This mechanical robustness ensures the tube can support itself and its contents without breaking under load.

Outstanding Chemical and Corrosion Resistance

High-purity alumina is chemically inert, meaning it does not react with most acids, bases, or corrosive gases, even at high temperatures. This prevents both contamination of the processed material and degradation of the tube itself, which is critical in metallurgy and semiconductor manufacturing.

Critical Electrical Insulation

In electrically heated furnaces, alumina serves as a premier electrical insulator. This property is essential for protecting heating elements, preventing short circuits, and ensuring the overall operational safety of the equipment.

Understanding the Trade-offs

No material is without its limitations. Acknowledging them is key to successful implementation.

Brittleness is an Inherent Trait

Like most ceramics, alumina is strong but brittle. While it has immense compressive strength, it can be susceptible to fracture from sharp, direct impacts or high tensile stress. Careful handling and proper mechanical support are essential during installation and operation.

Purity Dictates Performance

The specified properties, especially maximum temperature and chemical resistance, are directly tied to the alumina's purity. A 99.7% pure tube will significantly outperform a lower-purity version. Selecting a grade below your application's requirements can lead to premature failure.

Design and Installation Matter

The performance of an alumina tube is part of a system. Failures can occur not from the material itself, but from poor furnace design, inadequate support structures that create stress points, or improper handling.

Making the Right Choice for Your Application

Your specific goal will determine which of alumina's advantages is most critical.

- If your primary focus is process purity and avoiding contamination: High-purity alumina's chemical inertness is its most valuable asset, ensuring a clean environment for sensitive materials.

- If your primary focus is reaching extreme temperatures (above 1600°C): The material's unmatched thermal stability ensures structural integrity where metals and lesser ceramics would fail.

- If your primary focus is long-term reliability and efficiency: The combination of thermal shock resistance, good conductivity, and mechanical strength minimizes downtime and reduces energy waste.

Ultimately, selecting high-purity alumina is an investment in process stability, operational safety, and long-term performance.

Summary Table:

| Property | Key Advantage |

|---|---|

| Thermal Stability | Withstands temperatures up to 1800°C without deformation |

| Thermal Conductivity | Ensures uniform heat distribution for consistent results |

| Thermal Shock Resistance | Prevents cracking during rapid temperature changes |

| Mechanical Strength | High compressive and flexural strength for durability |

| Chemical Resistance | Inert to acids, bases, and corrosive gases |

| Electrical Insulation | Protects against short circuits for safety |

Upgrade your high-temperature processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, delivering enhanced efficiency, safety, and reliability. Contact us today to discuss how we can optimize your furnace applications!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the material requirements for furnace tubes? Optimize Performance and Safety in High-Temperature Labs

- How do roller kilns and tube furnaces differ in their use of Alumina ceramic tubes? Compare Transport vs. Containment

- How does a vertical tube furnace facilitate the simulation of the industrial sintering process for iron ores?

- What is flash vacuum pyrolysis and how is a tube furnace utilized in this process? Unlock High-Temp Chemical Reactions

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision