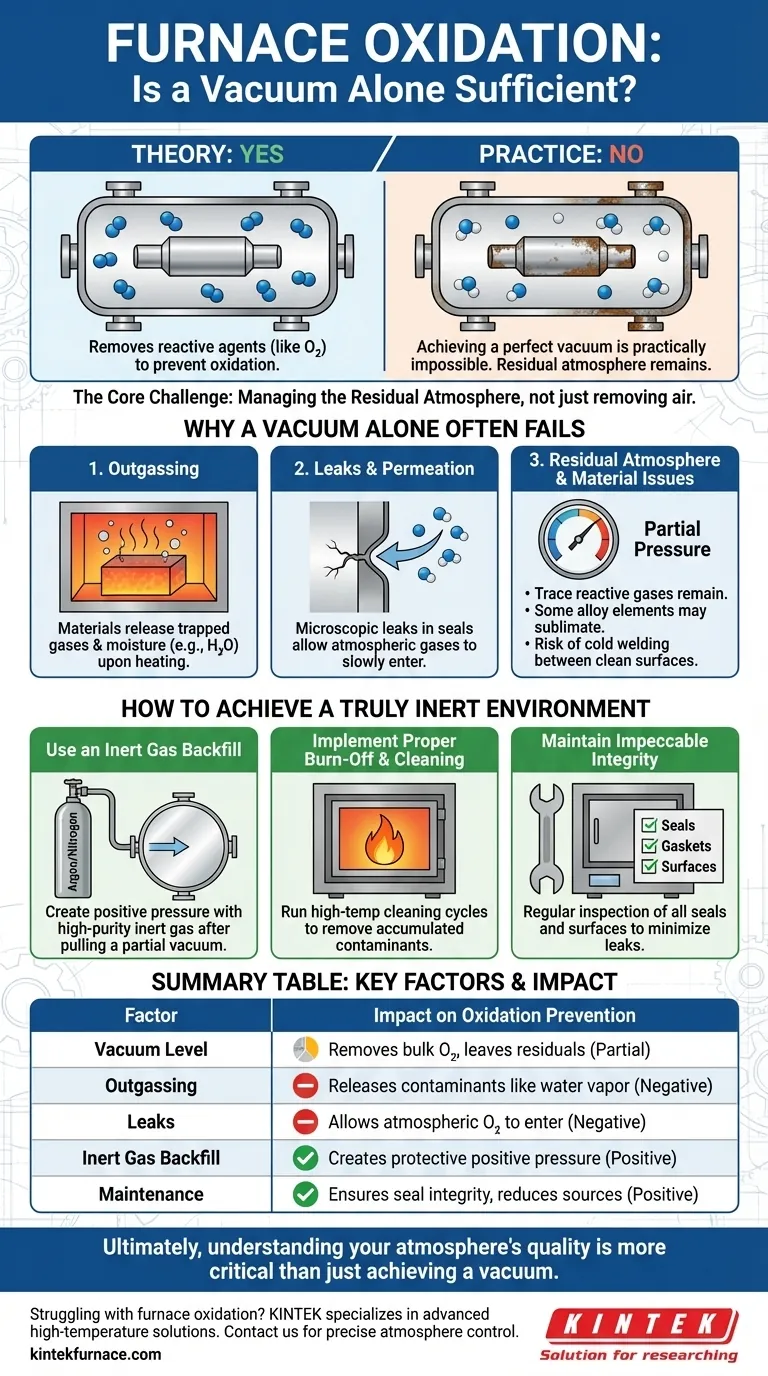

In theory, yes, but in practice, no. While a perfect vacuum would contain no oxygen and therefore completely prevent oxidation, achieving and maintaining such a state in an industrial furnace is practically impossible. The vacuum itself is only the first step; managing the residual atmosphere that remains is the critical factor for success.

The core challenge is not simply removing air from a furnace, but contending with the practical limitations of vacuum systems, such as residual gases, outgassing from the material itself, and microscopic leaks that can compromise an otherwise inert environment.

The Principle of Vacuum Protection

How a Vacuum Prevents Oxidation

Oxidation is a chemical reaction that requires a reactive agent, most commonly oxygen. At elevated temperatures, metals become highly susceptible to reacting with any oxygen present in their environment.

A vacuum furnace operates on a simple principle: by mechanically removing the atmosphere from a sealed chamber, you remove the vast majority of the oxygen. This protects the material from oxidation and other contamination during the heating process.

The Myth of the "Perfect" Vacuum

A perfect vacuum is a theoretical volume of space that is entirely empty of matter. In reality, every vacuum furnace contains a residual atmosphere with some level of partial pressure.

The effectiveness of the furnace is determined by the quality of the vacuum—how low the pressure is and what gases make up the remaining atmosphere. Even in a high-vacuum environment, trace amounts of reactive gases can remain.

Why a Vacuum Alone is Often Insufficient

Achieving a low-pressure environment is only half the battle. Several factors can introduce or release oxygen and other contaminants into the system, undermining the vacuum's protective effect.

The Problem of Outgassing

As materials and the furnace's internal components (like graphite fixtures) are heated, they release adsorbed or trapped gases and moisture. This process, known as outgassing, can release significant amounts of water vapor (H₂O) and other reactive gases directly into the chamber, contaminating the vacuum.

Leaks and Permeation

No system is perfectly sealed. Microscopic leaks in gaskets, seals, and fittings can allow atmospheric gases to slowly enter the furnace chamber. Over the course of a long heating cycle, even a small leak can compromise the integrity of the environment.

Material-Specific Limitations

Under a deep vacuum, some elements in metal alloys can sublimate, turning directly from a solid into a gas. This vaporization can alter the composition of the alloy. In other cases, perfectly clean metal surfaces in a vacuum can bond together unintentionally, a phenomenon known as cold welding.

Understanding the Practical Trade-offs

Pursuing a deeper vacuum is not always the best or most cost-effective solution. It introduces its own set of engineering and operational challenges.

The Cost of a Deeper Vacuum

Achieving higher vacuum levels requires more sophisticated, expensive, and energy-intensive pumping systems. These systems also demand more rigorous maintenance to manage wear and tear and ensure their performance does not degrade over time.

Thermodynamic Cooling Challenges

A vacuum is an excellent thermal insulator. While this is beneficial during heating, it makes cooling a slow and difficult process. Rapid, controlled cooling is often critical for achieving the desired metallurgical properties, and a deep vacuum complicates this.

Process Control is Critical

The process does not end when the heat is turned off. If air is introduced into the furnace chamber while the parts are still at an elevated temperature, rapid and severe oxidation can occur. Proper process control ensures the workload is below its critical oxidation temperature before the vacuum is broken.

How to Achieve a Truly Inert Environment

Since a perfect vacuum is impractical, the goal is to create a sufficiently inert environment using a combination of techniques.

Use an Inert Gas Backfill

A common and highly effective procedure involves pulling a partial vacuum to remove the bulk of the air and then backfilling the chamber with a high-purity inert gas, such as argon or nitrogen. This creates a positive pressure of a non-reactive gas, which is often more practical and economical than chasing an ultra-high vacuum.

Implement Proper Burn-Off and Cleaning Cycles

To combat outgassing, furnaces should undergo regular high-temperature cleaning cycles while empty to burn off accumulated contaminants. For sensitive loads, a preliminary "bake-out" cycle at a lower temperature can be used to drive off moisture and adsorbed gases before the main heating process begins.

Maintain Impeccable Furnace Integrity

The most fundamental step is ensuring the furnace itself is in optimal condition. This involves regular inspection and maintenance of all seals, gaskets, and chamber surfaces to minimize leaks and potential sources of outgassing.

Making the Right Choice for Your Process

- If your primary focus is general heat treating: A partial vacuum followed by an inert gas backfill is typically the most robust and cost-effective method for preventing oxidation.

- If your primary focus is high-purity brazing or processing sensitive alloys: A deeper vacuum combined with strict process controls and a preliminary bake-out cycle is necessary to minimize all sources of contamination.

- If you are consistently fighting oxidation: Focus first on furnace maintenance and leak detection, as a compromised chamber is the most common cause of failure.

Ultimately, understanding the quality of your atmosphere is more important than simply achieving a vacuum.

Summary Table:

| Factor | Impact on Oxidation Prevention |

|---|---|

| Vacuum Level | Removes bulk oxygen but may leave residual gases |

| Outgassing | Releases contaminants like water vapor and gases |

| Leaks | Allows atmospheric oxygen to enter over time |

| Inert Gas Backfill | Creates positive pressure with non-reactive gases for better protection |

| Maintenance | Ensures seal integrity and reduces contamination sources |

Struggling with oxidation in your furnace processes? KINTEK specializes in advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs, ensuring precise atmosphere control and enhanced material protection. Contact us today to optimize your furnace setup and achieve superior results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics