In the biomedical field, PECVD is primarily used to deposit ultra-thin, functional coatings onto medical devices. This process, known as Plasma-Enhanced Chemical Vapor Deposition, excels at creating biocompatible surfaces on implants, fabricating the sensitive layers of biosensors, and developing advanced platforms for drug delivery and cell culture research. Its key advantage is the ability to operate at low temperatures, which is critical for protecting the heat-sensitive materials common in modern medical technology.

The fundamental value of PECVD in biomedicine is its ability to engineer a device's surface properties—like biocompatibility or sensor reactivity—independently of its bulk material. This is achieved at low temperatures, making it possible to coat sensitive or complex devices without causing thermal damage.

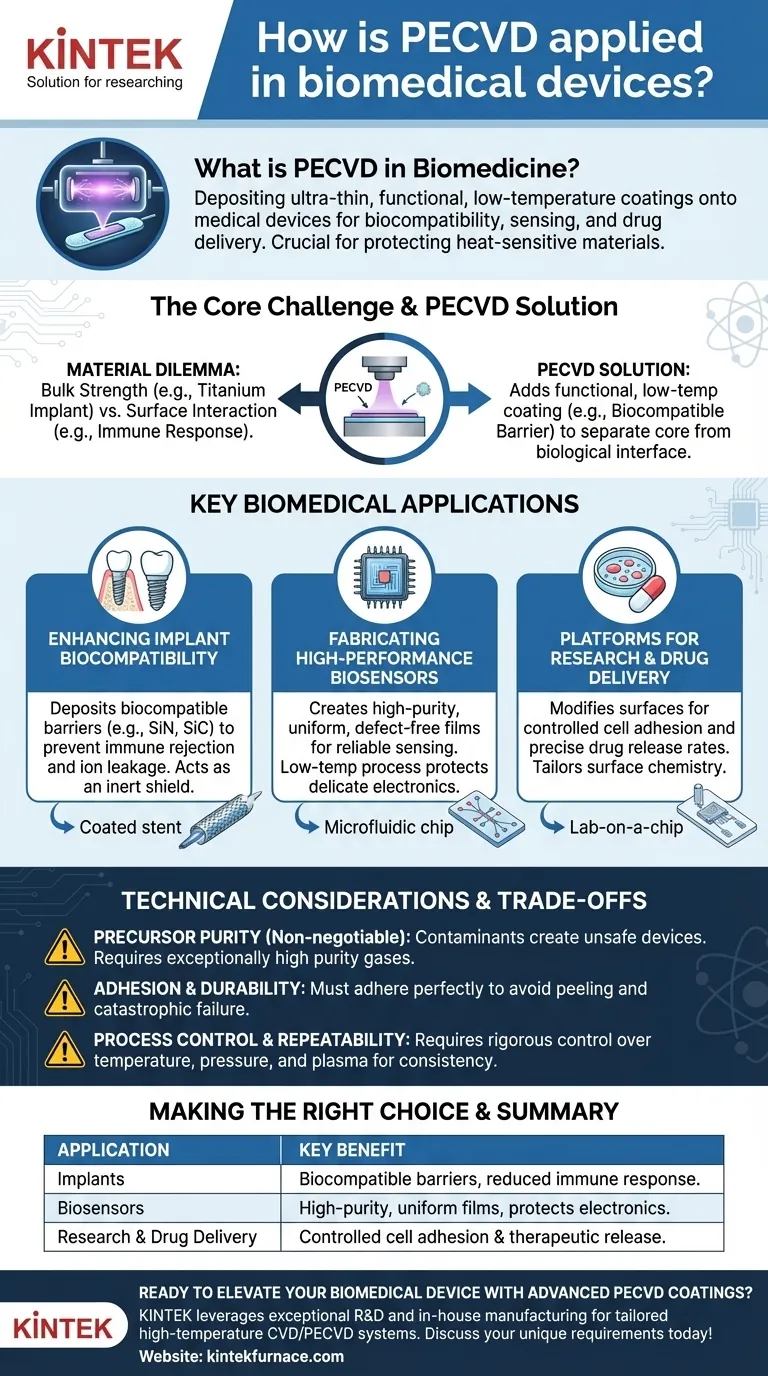

The Core Challenge: Separating Bulk Strength from Surface Interaction

Medical devices present a fundamental engineering conflict. A device's core material is chosen for its bulk properties like strength, flexibility, or conductivity, but its surface is what interacts directly with the highly sensitive biological environment.

The Material Dilemma in Medical Devices

An orthopedic implant, for example, must be made from a strong, durable metal like titanium to withstand mechanical stress. However, the raw metal surface can trigger an immune response or leach metallic ions into the body over time.

Similarly, a biosensor's substrate may need specific mechanical properties, but its sensing capability depends entirely on a different, specialized material at its surface.

How PECVD Provides the Solution

PECVD resolves this conflict by allowing engineers to add a functionally distinct thin film to a finished component. It uses an energized plasma to deposit a coating from a precursor gas, a process that doesn't require the high temperatures of other deposition methods.

This effectively lets you choose the best material for the device's structure and then apply the perfect material for its biological interface as a separate, final layer.

Key Biomedical Applications of PECVD

PECVD's versatility has made it a crucial tool across several areas of biomedical engineering. Its ability to control film properties like thickness, purity, and composition is essential for creating reliable and safe devices.

Enhancing Biocompatibility of Implants

PECVD is used to deposit a biocompatible barrier on medical implants, including orthopedic joints, dental implants, and cardiovascular stents.

These coatings, often ceramic-like materials such as silicon nitride (SiN) or silicon carbide (SiC), act as an inert shield. They prevent the underlying implant material from directly contacting living tissue, which significantly reduces the risk of immune rejection, inflammation, and ion leakage.

Fabricating High-Performance Biosensors

The performance of a biosensor depends on the quality and uniformity of its sensing layer. PECVD deposits the high-purity, defect-free films required for reliable and repeatable measurements.

Because the process is low-temperature, these sensitive films can be deposited directly onto substrates containing delicate electronics or microfluidic channels without causing damage.

Creating Platforms for Research and Drug Delivery

In biomedical research, PECVD is used to modify the surfaces of lab equipment, such as petri dishes or microfluidic chips, to promote or prevent cell adhesion.

This technology is also being explored for drug delivery systems, where a precisely engineered coating can control the release rate of a therapeutic agent from an implantable device.

Understanding the Trade-offs and Technical Considerations

While powerful, PECVD is not a simple solution. Its successful application in the highly regulated medical field requires navigating significant technical challenges.

Precursor Purity is Non-Negotiable

The gases used in the PECVD process must be of exceptionally high purity. Any contaminants in the gas can be incorporated into the final film, potentially creating a toxic surface and rendering the medical device unsafe.

Adhesion and Durability

The deposited film must adhere perfectly to the device's surface for its entire operational lifetime. Any peeling or delamination of the coating in the body is a catastrophic failure that can release debris and expose the reactive material underneath.

Process Control and Repeatability

For medical manufacturing, every single device must meet identical specifications. Achieving this level of consistency with a PECVD process requires rigorous control over variables like temperature, pressure, gas flow, and plasma power. This demands significant capital investment and process engineering expertise.

Making the Right Choice for Your Goal

The decision to use PECVD should be driven by the specific functional requirement you need to engineer onto your device's surface.

- If your primary focus is improving implant safety and longevity: Use PECVD to deposit a dense, inert, and biocompatible barrier coating that isolates the bulk material from the body.

- If your primary focus is developing a sensitive diagnostic tool: Leverage PECVD for its ability to create uniform, high-purity films essential for reliable biosensor performance without damaging underlying components.

- If your primary focus is controlling cellular interaction or drug release: Apply PECVD to precisely tailor the surface chemistry and morphology of a device for advanced research or therapeutic applications.

Ultimately, PECVD empowers you to solve surface-level challenges without compromising the core function of your biomedical device.

Summary Table:

| Application | Key Benefits of PECVD |

|---|---|

| Implants (e.g., orthopedic, dental) | Deposits biocompatible barriers (e.g., SiN, SiC) to reduce immune response and ion leakage |

| Biosensors | Creates high-purity, uniform films for reliable sensing without damaging electronics |

| Research & Drug Delivery | Modifies surfaces for controlled cell adhesion and therapeutic release |

| General Advantages | Low-temperature operation, independent surface engineering, versatility in film properties |

Ready to elevate your biomedical device with advanced PECVD coatings? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide tailored high-temperature furnace solutions, including our CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for implants, biosensors, and more. Contact us today to discuss how we can enhance your device's safety, performance, and innovation!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is resistance heating and how is it classified? Discover the Best Method for Your Thermal Needs

- What are the classifications of CVD based on vapor characteristics? Optimize Your Thin Film Deposition Process

- What are the drawbacks of CVD compared to PECVD? Key Limitations for Your Lab

- How does PECVD contribute to semiconductor manufacturing? Enable Low-Temperature, High-Quality Film Deposition

- What parameters control the quality of PECVD-deposited films? Master Key Variables for Superior Film Properties