Cooling in a vacuum furnace is achieved by overcoming the absence of air, using either slow thermal radiation or, more commonly, by introducing a high-pressure inert gas to force rapid convective cooling. This process is supplemented by an external water-cooling system that protects the furnace shell and creates a heat sink for the energy being removed from the chamber.

The core challenge of vacuum cooling is the lack of a medium for heat transfer. The solution is to either embrace slow, radiative cooling or to temporarily introduce a controlled gas atmosphere specifically to enable rapid, forced convection, giving operators precise control over the final properties of the material.

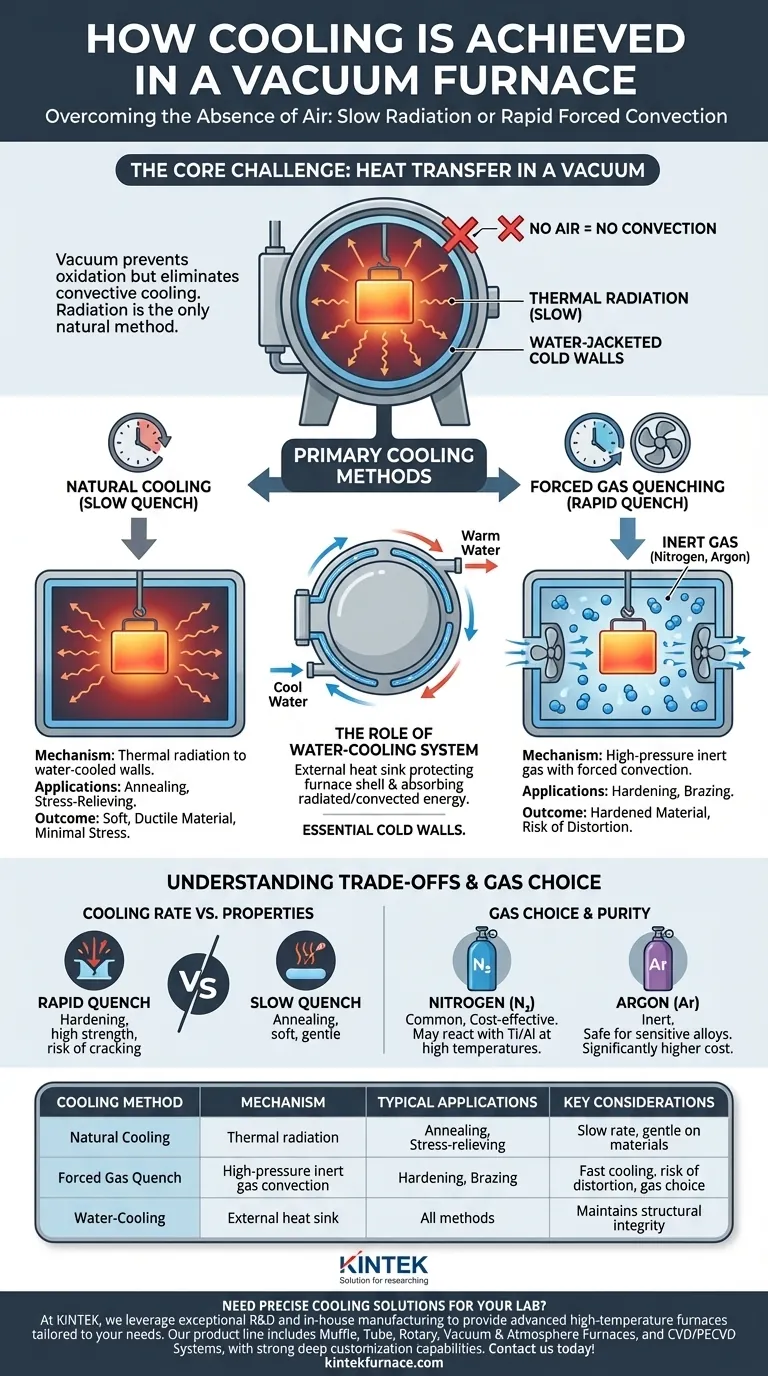

The Unique Challenge: Heat Transfer in a Vacuum

To understand vacuum furnace cooling, we must first recognize the environment. The furnace creates a vacuum to prevent oxidation and contamination during heating. This same vacuum, however, presents a significant obstacle for cooling.

The Problem of Convection

In a normal atmosphere, heat is primarily transferred away from a hot object via convection, where the surrounding air heats up, rises, and is replaced by cooler air.

In a vacuum, there is no air or gas to facilitate this process. Convective cooling is effectively eliminated.

The Dominance of Radiation

Without a gas medium, the only significant way for a hot workpiece to cool is through thermal radiation. The part radiates heat energy directly to the cooler, water-jacketed walls of the furnace.

This process is inherently slow and its rate is difficult to adjust, which is unsuitable for metallurgical processes that demand rapid cooling.

Primary Cooling Methods Explained

Vacuum furnaces employ distinct strategies to manage the cooling cycle, ranging from slow and gentle to extremely fast.

Natural Cooling (Slow Quench)

The simplest method is natural cooling. After the heating elements are turned off, the workpiece is left inside the vacuum chamber.

It cools slowly and gradually, purely by radiating its heat to the furnace walls. This is often used for processes like annealing, where a soft and stress-free material structure is the desired outcome.

Forced Gas Quenching (Rapid Quench)

This is the most common method for achieving rapid cooling. The process involves backfilling the sealed, hot chamber with a high-pressure, inert gas like nitrogen or argon.

This gas creates an artificial atmosphere, instantly enabling forced convection. High-power fans then circulate this gas at high velocity, moving it between the hot workpiece and the cold furnace walls, rapidly transferring heat out of the part.

The Role of the Water-Cooling System

A critical, yet indirect, component of the cooling process is the water-cooling system. This system circulates water through the furnace shell, cover, and other components.

Its primary purpose is not to cool the workpiece directly. Instead, it maintains the structural integrity of the furnace and provides the essential cold wall that acts as a heat sink, absorbing the thermal energy radiated or convected from the part inside.

Understanding the Trade-offs

The choice of cooling method is a critical process variable with direct consequences for the final product.

Cooling Rate vs. Material Properties

A rapid gas quench is necessary for hardening processes, where the material must be cooled quickly to achieve a specific crystalline structure (e.g., martensite in steel).

However, this rapid cooling can introduce significant internal stresses, distortion, or even cracking in complex geometries or sensitive materials. A slower, natural cool is far gentler but results in a softer, more ductile material.

Gas Choice and Purity

Nitrogen is the most common quenching gas because it is effective and relatively inexpensive. However, at high temperatures, it can react with certain alloys, such as those containing titanium or aluminum, forming undesirable nitrides on the surface.

Argon is almost completely inert and will not react with any workpiece material. It is the safer choice for sensitive alloys but comes at a significantly higher cost.

Equipment Complexity and Cost

A furnace designed only for natural cooling is relatively simple. A system capable of high-pressure gas quenching requires a reinforced chamber, powerful fan motors, a gas heat exchanger, and complex control systems, making it a much larger capital investment.

Selecting the Right Cooling Process

Your choice of cooling method must be driven entirely by the desired final material properties.

- If your primary focus is hardening or achieving high strength: You require a rapid forced gas quench to lock in a hard metallurgical structure.

- If your primary focus is annealing or stress-relieving: A slow, controlled natural cooling cycle in a vacuum is the correct approach to produce a soft, ductile component.

- If your primary focus is brazing or processing reactive metals: You must use a highly inert gas like argon for any forced cooling to prevent unwanted surface reactions.

By mastering the removal of heat, you gain precise control over the microstructure, performance, and integrity of your final components.

Summary Table:

| Cooling Method | Mechanism | Typical Applications | Key Considerations |

|---|---|---|---|

| Natural Cooling (Slow Quench) | Thermal radiation to water-cooled walls | Annealing, stress-relieving | Slow rate, gentle on materials, minimal stress |

| Forced Gas Quenching (Rapid Quench) | High-pressure inert gas (e.g., nitrogen, argon) with forced convection | Hardening, brazing | Fast cooling, risk of distortion, gas choice affects purity and cost |

| Water-Cooling System | External heat sink for furnace protection | All methods | Maintains structural integrity, enables heat dissipation |

Need precise cooling solutions for your lab? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnaces tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization capabilities to meet unique experimental requirements. Whether you're hardening, annealing, or processing reactive metals, our expertise ensures optimal performance and material integrity. Contact us today to discuss how we can enhance your laboratory's efficiency and results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion