In essence, chamber customization allows a vacuum furnace to be precisely engineered for a specific task, directly impacting final product quality, operational efficiency, and long-term durability. It moves beyond a one-size-fits-all approach by tailoring the furnace's internal environment to the exact requirements of the materials being processed, from preventing contamination to optimizing energy use.

The core benefit of chamber customization is not about adding features, but about achieving process control. It transforms the furnace from a generic heating tool into a precision instrument engineered to guarantee material integrity, reduce operational costs, and maximize throughput for specific, high-value applications.

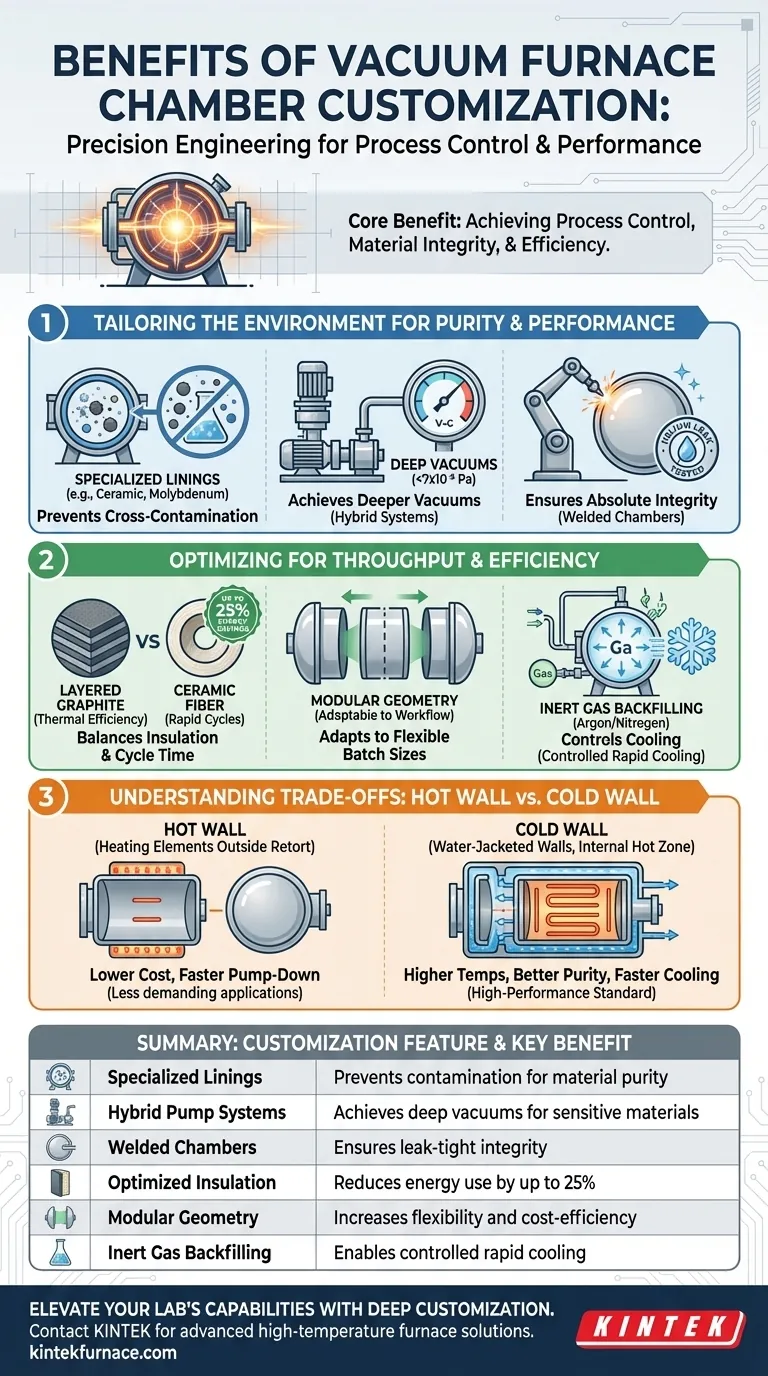

Tailoring the Environment for Purity and Performance

The primary function of a vacuum furnace is to create a controlled, contaminant-free environment. Customization ensures this environment is perfectly matched to the process.

Preventing Cross-Contamination with Specialized Linings

Different processes leave behind different residues. Using material-specific linings, such as ceramic fiber or refractory metals (like molybdenum or tungsten), prevents elements from one batch from contaminating the next.

This is critical when switching between materials, as even microscopic outgassing from a previous run can compromise the integrity of high-performance alloys or sensitive electronics.

Achieving Deeper Vacuums with Hybrid Pump Systems

Standard vacuum pumps may not be sufficient for materials that are extremely sensitive to oxidation.

A customized furnace can integrate a hybrid pump system, combining mechanical, diffusion, and turbomolecular pumps. This allows the system to achieve much deeper vacuum levels—down to 7×10⁻⁴ Pa or lower—which is essential for processing superalloys and advanced ceramics.

Ensuring Absolute Integrity with Welded Chambers

Even a minuscule leak can ruin a high-value batch. Customization often involves using welded stainless steel chambers instead of mechanically sealed ones.

These chambers are validated using rigorous helium leak testing to guarantee leak-tight integrity, providing the purest possible environment for the heat treatment process.

Optimizing for Throughput and Efficiency

Beyond purity, customization directly impacts the operational economics of the furnace, from energy costs to cycle times.

Balancing Insulation and Cycle Time

The choice of insulation is a critical balancing act. Layered graphite felt offers excellent thermal efficiency at high temperatures, while ceramic fiber can be better for rapid heating and cooling cycles.

Optimizing the insulation package can reduce energy consumption by up to 25% and significantly shorten cycle times, increasing the furnace's overall throughput.

Adapting to Your Workflow with Modular Geometry

A furnace chamber with a fixed size can be inefficient. Modular and scalable geometry allows the internal volume to be adapted to different batch sizes.

This ensures that you are not wasting energy and time heating an unnecessarily large, empty space, making operations more flexible and cost-effective.

Controlling Cooling with Inert Gas Backfilling

The cooling phase is just as important as the heating phase. Custom systems allow for precise inert gas backfilling with argon or nitrogen.

This provides controlled, rapid cooling without introducing reactive elements like oxygen, which is vital for achieving specific material microstructures and properties.

Understanding the Trade-offs: Hot Wall vs. Cold Wall

Not all furnace designs are equal. The choice between a hot wall and cold wall chamber involves distinct cost and performance considerations.

The Case for Hot Wall Furnaces

Hot wall designs, where the heating elements are outside the vacuum retort, are generally less expensive to manufacture.

The internal vacuum volume is typically smaller, which allows for faster pump-down times with smaller, less costly pumps. This design is often suitable for less demanding, lower-temperature applications.

The Dominance of Cold Wall Furnaces

Most high-performance industrial vacuum furnaces use a cold wall design. The chamber walls are water-jacketed to remain cool while the heat is contained within an internal "hot zone."

This design allows for higher temperatures, better vacuum purity, and faster cooling rates, making it the standard for critical applications in aerospace, medical, and electronics manufacturing.

Making the Right Choice for Your Goal

The decision to invest in customization depends entirely on your process requirements and materials.

- If your primary focus is material purity and performance: Prioritize specialized linings, hybrid pump systems for deep vacuums, and a welded, leak-tested chamber.

- If your primary focus is operational efficiency and cost: Focus on optimized insulation for energy savings and a modular chamber geometry for production flexibility.

- If you are processing highly sensitive or diverse materials: A fully customized solution that combines contamination control with thermal efficiency is necessary to ensure consistent quality and prevent costly failures.

Ultimately, chamber customization transforms a vacuum furnace from a generic tool into a precision instrument engineered for your specific success.

Summary Table:

| Customization Feature | Key Benefit |

|---|---|

| Specialized Linings | Prevents contamination for material purity |

| Hybrid Pump Systems | Achieves deep vacuums for sensitive materials |

| Welded Chambers | Ensures leak-tight integrity |

| Optimized Insulation | Reduces energy use by up to 25% |

| Modular Geometry | Increases flexibility and cost-efficiency |

| Inert Gas Backfilling | Enables controlled rapid cooling |

Ready to transform your lab's capabilities with a custom vacuum furnace? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements. Achieve superior material purity, operational efficiency, and long-term durability—contact us today to discuss your specific needs and elevate your processes!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- Why must sintering equipment maintain a high vacuum for high-entropy carbides? Ensure Phase Purity and Peak Density

- Why is a vacuum hot press sintering furnace required for nanocrystalline ceramics? Preserve Structure with Pressure

- How do vacuum sintering and annealing furnaces contribute to the densification of NdFeB magnets?

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance