The physical orientation of copper foil is the determining factor in successfully synthesizing single-crystal Cu(111). To ensure the transformation from a polycrystalline structure to a single crystal, you must place the copper foil horizontally across the top of the high-purity quartz boat.

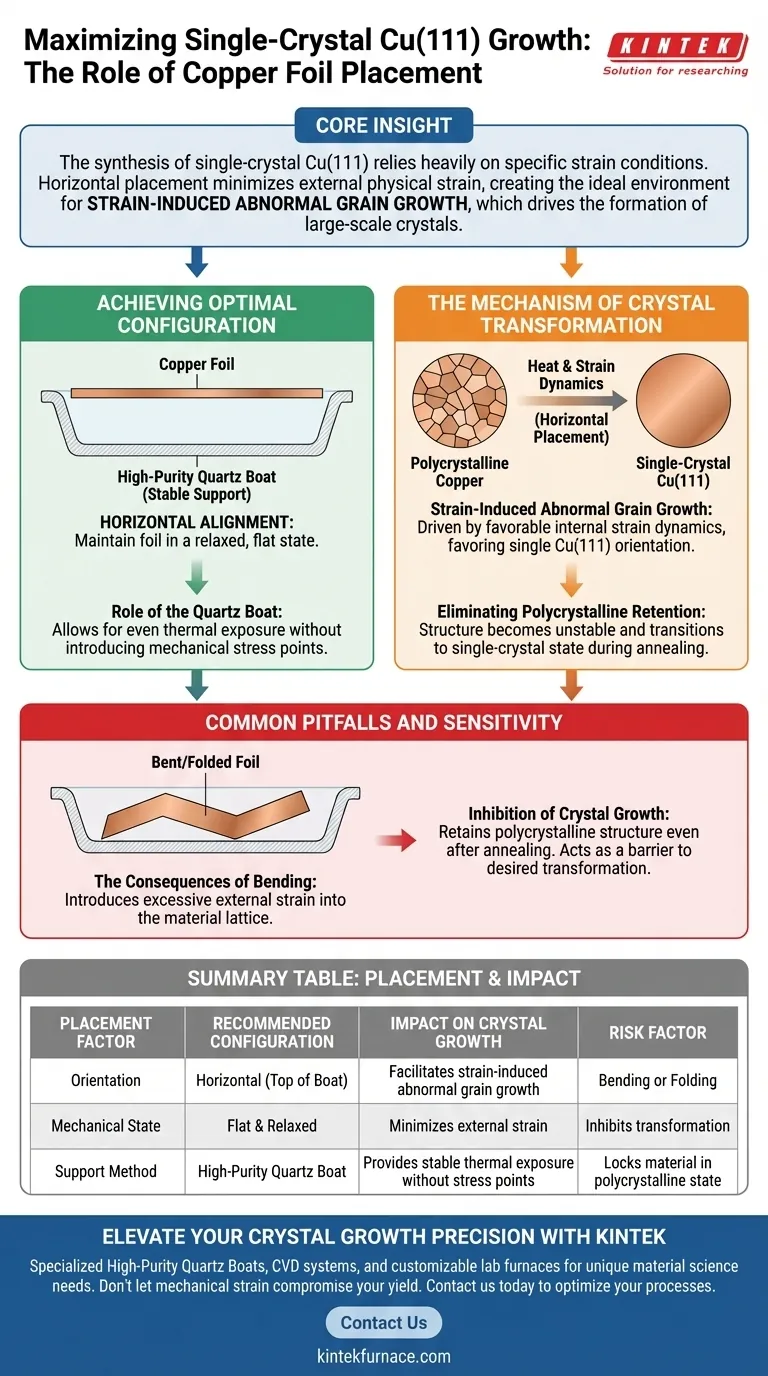

Core Insight: The synthesis of single-crystal Cu(111) relies heavily on specific strain conditions. Horizontal placement minimizes external physical strain, creating the ideal environment for strain-induced abnormal grain growth, which drives the formation of large-scale crystals.

Achieving Optimal Configuration

Horizontal Alignment

The copper foil must be positioned horizontally on the top of the quartz boat.

This specific placement is not arbitrary; it is designed to maintain the foil in a relaxed, flat state during the heating process.

The Role of the Quartz Boat

The high-purity quartz boat acts as a stable support structure.

By resting the foil on top, the boat allows for even thermal exposure without introducing mechanical stress points that would occur if the foil were wedged inside or draped unevenly.

The Mechanism of Crystal Transformation

Strain-Induced Abnormal Grain Growth

The process of converting polycrystalline copper into a centimeter-scale single crystal is driven by a mechanism known as strain-induced abnormal grain growth.

For this mechanism to function correctly, the material must not be subjected to excessive external deformation forces.

Horizontal placement ensures that the internal strain dynamics favor the growth of the single Cu(111) crystal orientation rather than competing grains.

Eliminating Polycrystalline Retention

When the foil is positioned correctly, the polycrystalline structure is unstable and transitions to the single-crystal state during annealing.

This transformation is the primary goal of the preparation process.

Common Pitfalls and Sensitivity

The Consequences of Bending

A common error is bending or folding the copper foil to fit it into the apparatus.

Research indicates that any significant bending introduces excessive strain into the material lattice.

Inhibition of Crystal Growth

This added strain from folding acts as a barrier to the desired transformation.

Instead of evolving into single-crystal Cu(111), a bent foil will retain its polycrystalline structure even after the annealing process is complete.

Ensuring Process Success

To maximize your yield of single-crystal copper, apply the following guidelines based on your preparation setup:

- If your goal is high-quality Single-Crystal Cu(111): Ensure the foil is perfectly flat and rests horizontally on top of the boat to facilitate strain-induced abnormal grain growth.

- If your goal is troubleshooting failed samples: Inspect the pre-annealing setup for any folds, bends, or mechanical stress that may have locked the material in a polycrystalline state.

Minimize physical deformation during loading to ensure the thermodynamic conditions necessary for single-crystal formation.

Summary Table:

| Placement Factor | Recommended Configuration | Impact on Crystal Growth |

|---|---|---|

| Orientation | Horizontal (Top of Boat) | Facilitates strain-induced abnormal grain growth |

| Mechanical State | Flat & Relaxed | Minimizes external strain to prevent polycrystalline retention |

| Support Method | High-Purity Quartz Boat | Provides stable thermal exposure without stress points |

| Risk Factor | Bending or Folding | Inhibits transformation; locks material in polycrystalline state |

Elevate Your Crystal Growth Precision with KINTEK

Precision in single-crystal synthesis begins with the right thermal environment and high-purity apparatus. Backed by expert R&D and manufacturing, KINTEK offers specialized High-Purity Quartz Boats, CVD systems, and a range of customizable lab high-temp furnaces—including Muffle, Tube, Rotary, and Vacuum systems—engineered to meet your unique material science needs.

Don't let mechanical strain or thermal instability compromise your Cu(111) yield. Contact us today to discover how our high-performance equipment can optimize your laboratory processes and ensure consistent, high-quality results.

Visual Guide

References

- Jia Tu, Mingdi Yan. Chemical Vapor Deposition of Monolayer Graphene on Centimeter-Sized Cu(111) for Nanoelectronics Applications. DOI: 10.1021/acsanm.5c00588

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What is the function of a laboratory drying oven in the preparation of solid bismuth molybdate materials? Expert Tips

- How does optimizing fuel gas mass flow affect the thermal efficiency of an industrial furnace? Maximize Heat Retention

- Why introduce high-purity N2 during cooling after roasting? Preserve Sample Integrity and Prevent Oxidation

- What is the purpose of performing a 600 degree Celsius annealing treatment? Enhance AZO Thin Film Stability

- Why is the laboratory heating and boiling stage essential in the maceration process of wood fibers?

- How does a multi speed furnace work? Achieve Ultimate Comfort & Efficiency

- Why is a laboratory vacuum evaporation system essential for the preparation of electrodes in high-performance solar cells?

- How does the pre-oxidation process affect high-temperature alloys? Enhancing Surface Integrity for Steam Cracking