PECVD enables the deposition of Diamond-Like Carbon (DLC) by using an energy-rich plasma to break down carbon-containing gases into reactive ions and radicals inside a vacuum chamber. These energized particles are then accelerated onto a substrate, where their impact energy forces the carbon atoms to form a dense, amorphous film with a significant fraction of hard, diamond-like (sp3) chemical bonds, all without requiring the extreme temperatures and pressures of natural diamond formation.

At its core, the process uses the controlled energy of a plasma, not high heat, to construct a film atom-by-atom. This allows PECVD to create a metastable material—Diamond-Like Carbon—with exceptional hardness and low friction on a wide variety of surfaces.

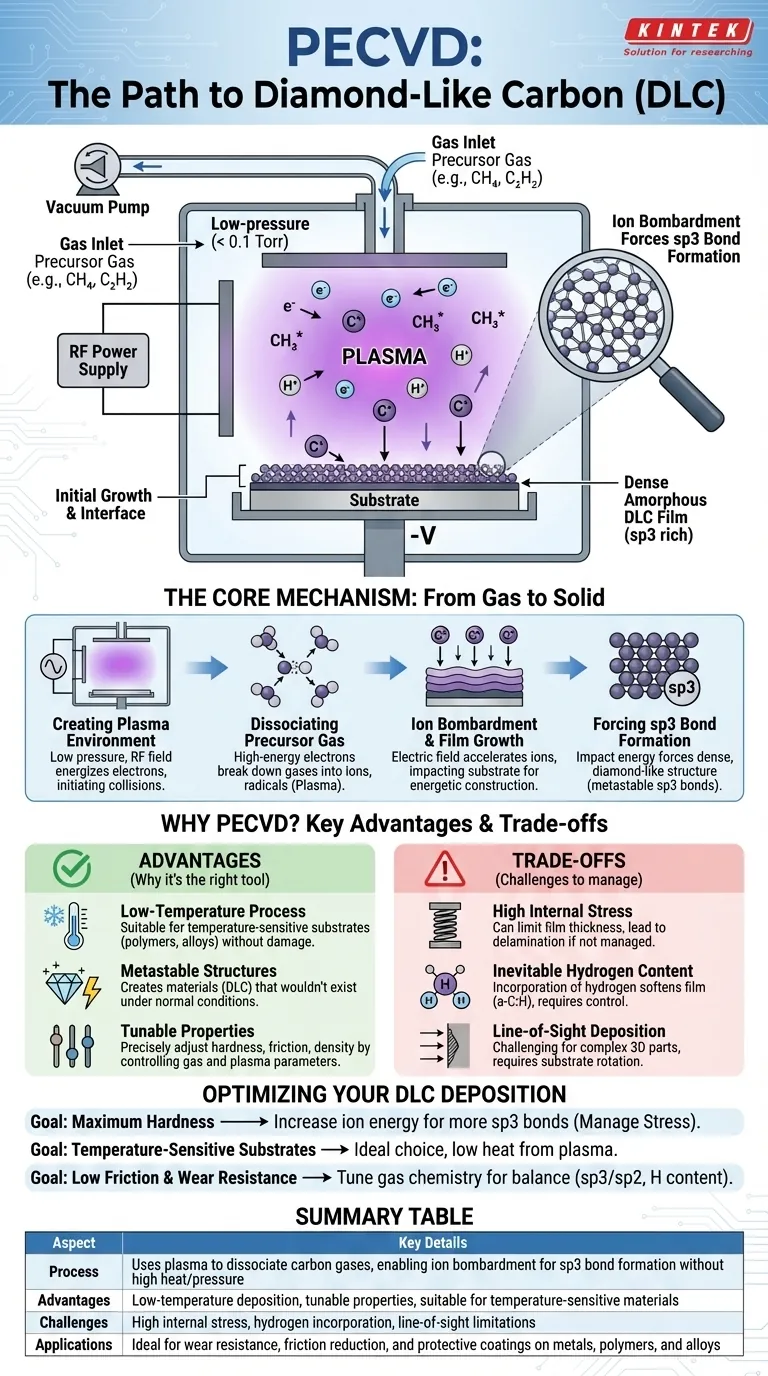

The Core Mechanism: From Gas to a Diamond-Like Solid

To understand how PECVD creates DLC, it's essential to visualize the process as a highly controlled, energetic construction at the atomic level. The system manipulates precursor gases in a low-pressure environment to build a solid film with unique properties.

Creating the Plasma Environment

The entire process occurs within a vacuum chamber held at very low pressure, typically below 0.1 Torr. A carbon-containing precursor gas, such as methane (CH₄) or acetylene (C₂H₂), is introduced into the chamber. An electrical field, often a radio frequency (RF) field, is applied between two electrodes.

This field energizes the free electrons naturally present in the gas, initiating a cascade of collisions.

Dissociating the Precursor Gas

The high-energy electrons collide with the neutral precursor gas molecules. These collisions are energetic enough to break the molecules apart, a process called dissociation.

This creates a soup of charged particles (ions), neutral radicals, and other molecular fragments. This ionized, reactive gas mixture is the plasma.

Ion Bombardment and Film Growth

The electric field that sustains the plasma also directs the positively charged carbon-containing ions toward the negatively biased substrate. They accelerate and strike the substrate surface with significant kinetic energy, a process known as ion bombardment.

This bombardment is not a gentle settling. It is an energetic impact that is fundamental to the film's growth and structure.

Forcing the sp3 Bond Formation

This is the critical step that creates the "diamond-like" properties. Carbon can form soft, graphite-like sp2 bonds or hard, diamond-like sp3 bonds.

The impact energy of the arriving ions forces surface atoms into a dense, tightly packed arrangement. This energetic deposition favors the formation of the metastable sp3 bonds within the amorphous carbon network. In essence, the ion energy substitutes for the immense thermal energy and pressure required to form natural diamond.

Why PECVD is the Right Tool for the Job

PECVD is not just one method for creating DLC; it is particularly well-suited for it due to several key advantages that other deposition techniques cannot easily match.

The Low-Temperature Advantage

Because the energy required for the reaction comes from the plasma rather than from heating the substrate, PECVD is a low-temperature process.

This allows DLC films to be deposited on temperature-sensitive materials like polymers, aluminum, or other alloys without causing damage, deformation, or altering their underlying properties.

Unlocking Metastable Structures

DLC is a metastable material, meaning it is not in its most stable thermodynamic state (which for carbon at standard conditions is graphite). It requires a constant input of energy to form and will not form under simple heating.

PECVD is a non-equilibrium process perfectly suited to creating such structures. The controlled plasma energy drives the formation of the desired sp3 bonds, building a material that otherwise wouldn't exist.

Tunable Properties

The final properties of the DLC film—its hardness, friction, density, and stress—are not fixed. They are directly related to the ratio of sp3 to sp2 bonds and the amount of hydrogen incorporated into the film.

By precisely adjusting process parameters like gas composition, pressure, and plasma power, an operator can tune the ion energy and density. This provides fine control over the film's final microstructure and performance characteristics.

Understanding the Trade-offs

While powerful, the PECVD process for DLC deposition involves inherent compromises that must be managed for successful application.

High Internal Stress

The same ion bombardment that creates the desirable hardness also induces significant compressive stress within the film.

If this stress becomes too high, it can limit the maximum thickness of the film and lead to delamination or poor adhesion to the substrate. Managing this stress is a primary challenge in process development.

Inevitable Hydrogen Content

When using hydrocarbon precursor gases (like methane), hydrogen is unavoidably incorporated into the growing film, creating what is known as hydrogenated amorphous carbon (a-C:H).

While sometimes desirable, this hydrogen content generally softens the film compared to hydrogen-free DLC. The amount of incorporated hydrogen is another critical parameter that must be controlled to achieve the desired properties.

Line-of-Sight Deposition

PECVD is fundamentally a line-of-sight process. The ions travel in relatively straight lines from the plasma to the substrate.

This can make achieving a uniform coating on complex, three-dimensional parts challenging without sophisticated substrate fixtures and rotation.

Optimizing Your DLC Deposition

Your approach to PECVD should be dictated by the specific performance goal for your coated component.

- If your primary focus is maximum hardness: You must optimize the process to increase ion energy, which promotes a higher fraction of

sp3bonds, but be prepared to manage the resulting internal stress. - If your primary focus is coating temperature-sensitive substrates: PECVD is your ideal choice, as the plasma provides the necessary reaction energy without requiring destructive substrate heat.

- If your primary focus is low friction and wear resistance: You will need to carefully tune the gas chemistry and plasma parameters to balance

sp3content, hydrogen incorporation, and the possible formation of a graphite-like surface layer.

By mastering the interplay between plasma, precursor gases, and ion energy, you can engineer custom DLC films for a vast range of demanding applications.

Summary Table:

| Aspect | Key Details |

|---|---|

| Process | Uses plasma to dissociate carbon gases, enabling ion bombardment for sp3 bond formation without high heat/pressure |

| Advantages | Low-temperature deposition, tunable properties, suitable for temperature-sensitive materials |

| Challenges | High internal stress, hydrogen incorporation, line-of-sight limitations |

| Applications | Ideal for wear resistance, friction reduction, and protective coatings on metals, polymers, and alloys |

Need a custom high-temperature furnace solution for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced PECVD systems, Muffle Furnaces, Tube Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and more. Our deep customization capabilities ensure precise solutions for your unique experimental needs, enhancing efficiency and performance. Contact us today to discuss how we can support your DLC deposition and other high-temperature processes!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the classifications of CVD based on vapor characteristics? Optimize Your Thin Film Deposition Process

- What are the advantages of plasma enhanced CVD? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What are the applications of PECVD? Unlock Low-Temperature Thin-Film Deposition

- How does the PECVD process work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What are the drawbacks of CVD compared to PECVD? Key Limitations for Your Lab