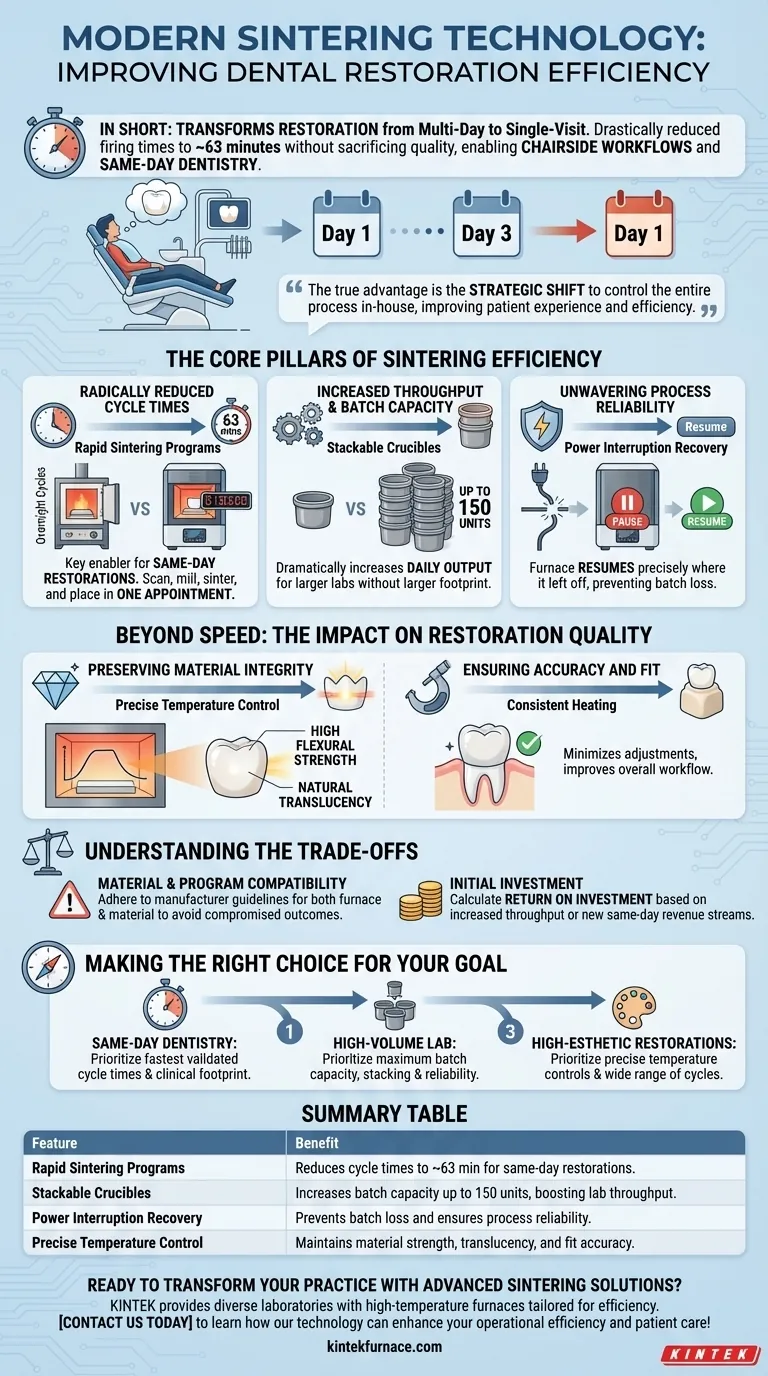

In short, modern sintering technology transforms dental restoration from a multi-day process into a single-visit procedure. By drastically reducing firing times to as little as 63 minutes without sacrificing material strength or aesthetics, these furnaces directly enable efficient chairside workflows and same-day dentistry.

The true advantage isn't just speed; it's the strategic shift it allows. Modern sintering empowers dental practices to control the entire restoration process in-house, leading to improved patient experiences and greater operational efficiency.

The Core Pillars of Sintering Efficiency

Modern sintering furnaces improve efficiency through a combination of speed, capacity, and reliability. These factors work together to redefine what's possible in a dental lab or clinic.

Radically Reduced Cycle Times

The most significant advancement is the development of rapid sintering programs. Where traditional furnaces required overnight cycles, modern units can complete the crystallization of a zirconia restoration in just over an hour.

This speed is the key enabler for same-day restorations. A patient can be scanned, the crown milled, and the final restoration sintered and placed within a single appointment.

Increased Throughput and Batch Capacity

For larger dental labs, efficiency is about volume. Modern furnaces address this with features like stackable crucibles.

Some models can process up to 150 units in a single run, dramatically increasing the lab's daily output without a proportional increase in equipment footprint or energy consumption.

Unwavering Process Reliability

Efficiency is lost when a process fails. New furnaces incorporate features like power interruption recovery.

If the power is cut, the furnace can resume the cycle precisely where it left off once power is restored. This prevents the loss of entire batches, saving significant time and material costs.

Beyond Speed: The Impact on Restoration Quality

A common concern with any accelerated process is a potential compromise in quality. However, modern sintering technology is engineered to enhance, not diminish, the final product.

Preserving Material Integrity

Rapid sintering is achieved through highly precise temperature control. The furnace follows specific heating and cooling protocols validated for modern zirconia materials.

This ensures the restoration reaches its optimal crystalline structure, achieving both high flexural strength and the desired translucency for a natural appearance.

Ensuring Accuracy and Fit

The quality of the sintering process directly impacts the final fit of the restoration. Inconsistent heating can lead to warping or an improper fit, requiring time-consuming chairside adjustments.

By firing restorations at precise temperatures and durations, modern furnaces produce predictable, accurate results, minimizing adjustments and improving overall workflow efficiency.

Understanding the Trade-offs

While the benefits are substantial, adopting this technology requires a clear understanding of the associated considerations.

Material and Program Compatibility

Not all zirconia materials are validated for all rapid sintering cycles. Using an unverified combination of material and program can lead to compromised strength or aesthetics.

It is critical to adhere to manufacturer guidelines for both the furnace and the restorative material to guarantee predictable, high-quality outcomes.

Initial Investment

High-speed, high-capacity sintering furnaces represent a significant capital investment compared to older, slower models.

The return on this investment must be calculated based on your specific operational goals, whether that's increased lab throughput or the new revenue streams from offering same-day dentistry.

Making the Right Choice for Your Goal

The ideal technology depends entirely on your practice or lab's primary objective.

- If your primary focus is same-day, chairside dentistry: Prioritize a furnace with the fastest validated cycle times that fits a clinical footprint.

- If your primary focus is high-volume lab production: Prioritize a furnace with maximum batch capacity and features like crucible stacking and process reliability.

- If your primary focus is specialized, high-esthetic restorations: Prioritize a furnace with the most precise temperature controls and a wide range of programmable cycles validated for diverse materials.

Ultimately, modern sintering technology empowers you to align your technical capabilities directly with your strategic business goals.

Summary Table:

| Feature | Benefit |

|---|---|

| Rapid Sintering Programs | Reduces cycle times to as little as 63 minutes for same-day restorations |

| Stackable Crucibles | Increases batch capacity up to 150 units, boosting lab throughput |

| Power Interruption Recovery | Prevents batch loss and ensures process reliability |

| Precise Temperature Control | Maintains material strength, translucency, and fit accuracy |

Ready to transform your dental practice or lab with advanced sintering solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with high-temperature furnaces tailored for efficiency. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique needs—whether for same-day dentistry, high-volume production, or specialized esthetic restorations. Contact us today to learn how our sintering technology can enhance your operational efficiency and patient care!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns