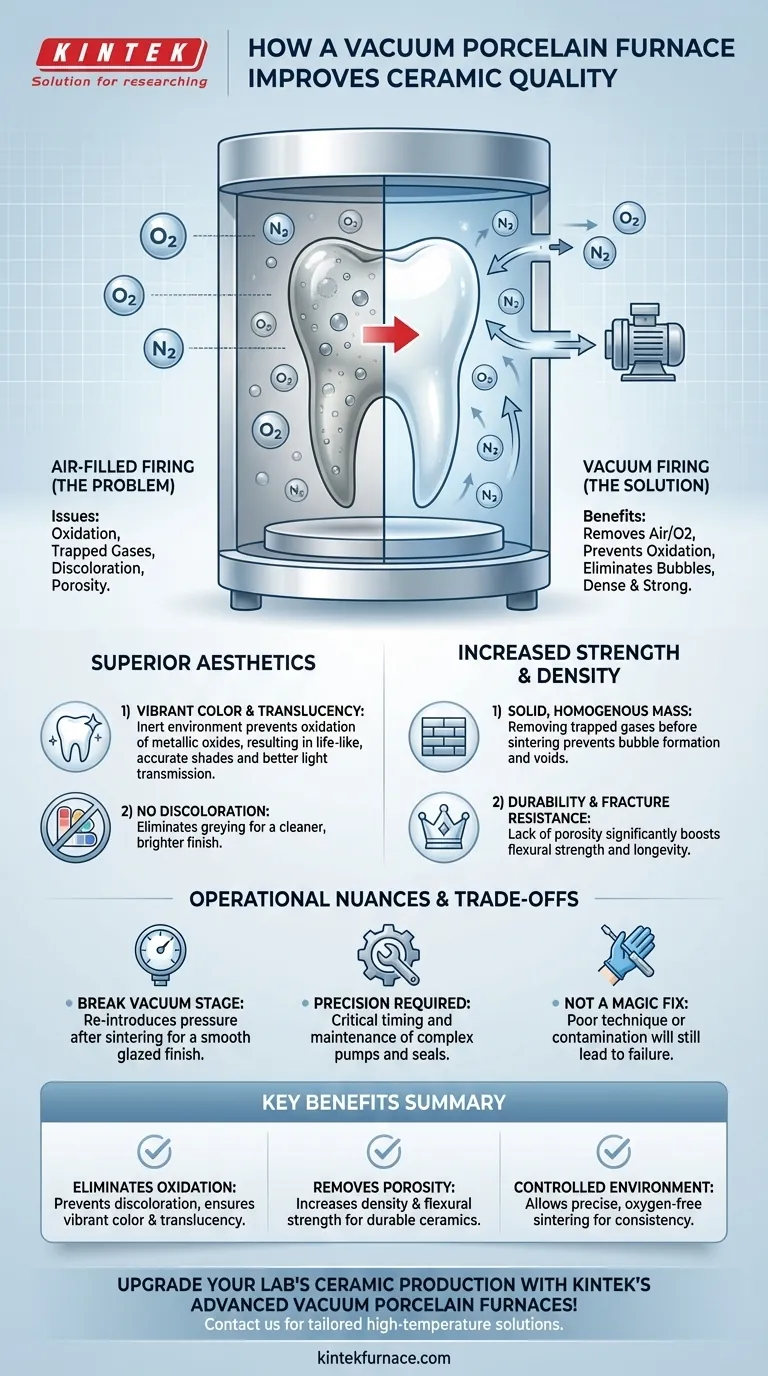

In short, a vacuum porcelain furnace improves ceramic quality by removing air from the firing chamber. This prevents oxygen from reacting with the porcelain, which eliminates discoloration and internal bubbles (porosity). The result is a final ceramic restoration that is denser, stronger, and has superior aesthetic properties like translucency and accurate color.

The core function of the vacuum is to create a controlled, oxygen-free environment during the critical sintering phase. By preventing oxidation and eliminating trapped gases, the furnace produces a ceramic structure with minimal internal defects, maximizing both its physical strength and its visual appeal.

The Core Problem: Firing Ceramics in Open Air

To understand the benefit of a vacuum, we must first examine the problems that arise when firing dental porcelain in a conventional, air-filled environment. The air we breathe is a mixture of gases, most notably nitrogen and about 21% oxygen.

The Issue of Oxidation

Porcelain contains metallic oxides that give it specific colors and optical properties. When heated in the presence of oxygen, these metals can further oxidize. This unwanted reaction often causes a "greying" or dulling effect, compromising the final shade and making it difficult to match the patient's natural teeth.

The Problem of Trapped Gases

As porcelain powder is heated, its individual particles begin to soften and fuse together—a process called sintering. In a normal atmosphere, air gets trapped in the microscopic spaces between these particles. As the temperature rises, this trapped air expands and forms bubbles, creating voids and porosity within the final ceramic structure.

How the Vacuum Furnace Provides the Solution

A vacuum furnace directly counteracts these two problems by evacuating the air from the firing chamber before and during the initial stages of the heating cycle.

Eliminating Oxidation for Superior Aesthetics

By removing nearly all the oxygen, the vacuum furnace creates an inert environment. This prevents the unwanted oxidation of metallic elements within the porcelain. The result is a cleaner, more vibrant color and a higher level of translucency, as light is not scattered or absorbed by discolored contaminants. This is critical for achieving life-like dental restorations.

Preventing Porosity for Increased Strength and Density

The vacuum removes the air from between the porcelain particles before they can fuse together. When the material reaches its sintering temperature, there are no trapped gases to form bubbles. The porcelain particles can coalesce into a solid, homogenous mass. This lack of porosity significantly increases the final density and flexural strength of the ceramic, making it more durable and resistant to fracture.

Understanding the Trade-offs and Operational Nuances

While essential for high-quality results, a vacuum furnace is a precision instrument whose operation involves important considerations.

The Critical "Break Vacuum" Stage

A restoration is not fired in a vacuum for the entire cycle. Once the porcelain has fully sintered into a dense mass, the vacuum is released. This "break vacuum" stage re-introduces atmospheric pressure, which helps to slightly compress the softened porcelain, further consolidating the structure and creating a smooth, glazed surface finish. The timing of this stage is critical.

Not a Substitute for Proper Technique

A vacuum furnace is a powerful tool, but it cannot fix fundamental errors. Poor porcelain buildup, incorrect condensation, or contamination of the material before firing will still result in a failed restoration. The furnace enhances the properties of properly handled material; it does not correct for poor craftsmanship.

Equipment Complexity and Maintenance

Vacuum furnaces are more complex than simple atmospheric ovens. They rely on pumps, seals, and sensors that require regular calibration and maintenance to function correctly. A leaking seal or a weak pump can compromise the vacuum level, negating the benefits of the process.

Applying This Knowledge for Optimal Results

Understanding how the vacuum functions allows you to fine-tune the process to achieve specific goals for your ceramic restorations.

- If your primary focus is aesthetics and translucency: Ensure a deep, stable vacuum is achieved well before the porcelain reaches its sintering temperature to completely prevent oxidation.

- If your primary focus is strength and durability: Prioritize the removal of all air to eliminate porosity, which means pulling the vacuum early in the cycle and holding it until full sintering is complete.

- If your primary focus is batch-to-batch consistency: Precisely control all firing parameters, paying close attention to the vacuum level, the temperature at which it's applied, and the exact moment it is released.

By mastering the environment within the furnace, you gain ultimate control over the properties of the final ceramic.

Summary Table:

| Key Benefit | How It Improves Ceramic Quality |

|---|---|

| Eliminates Oxidation | Prevents discoloration and greying, ensuring vibrant color and high translucency for better aesthetics |

| Removes Porosity | Eliminates internal bubbles, increasing density and flexural strength for durable, fracture-resistant ceramics |

| Controlled Environment | Allows precise sintering in an oxygen-free atmosphere, enhancing consistency and quality in dental restorations |

Upgrade your dental lab's ceramic production with KINTEK's advanced vacuum porcelain furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Achieve superior ceramic quality with reliable, durable equipment—contact us today to discuss how we can enhance your results!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency

- What safety measures should be followed when using a sintering furnace in dental labs? Ensure Safe, High-Quality Dental Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations