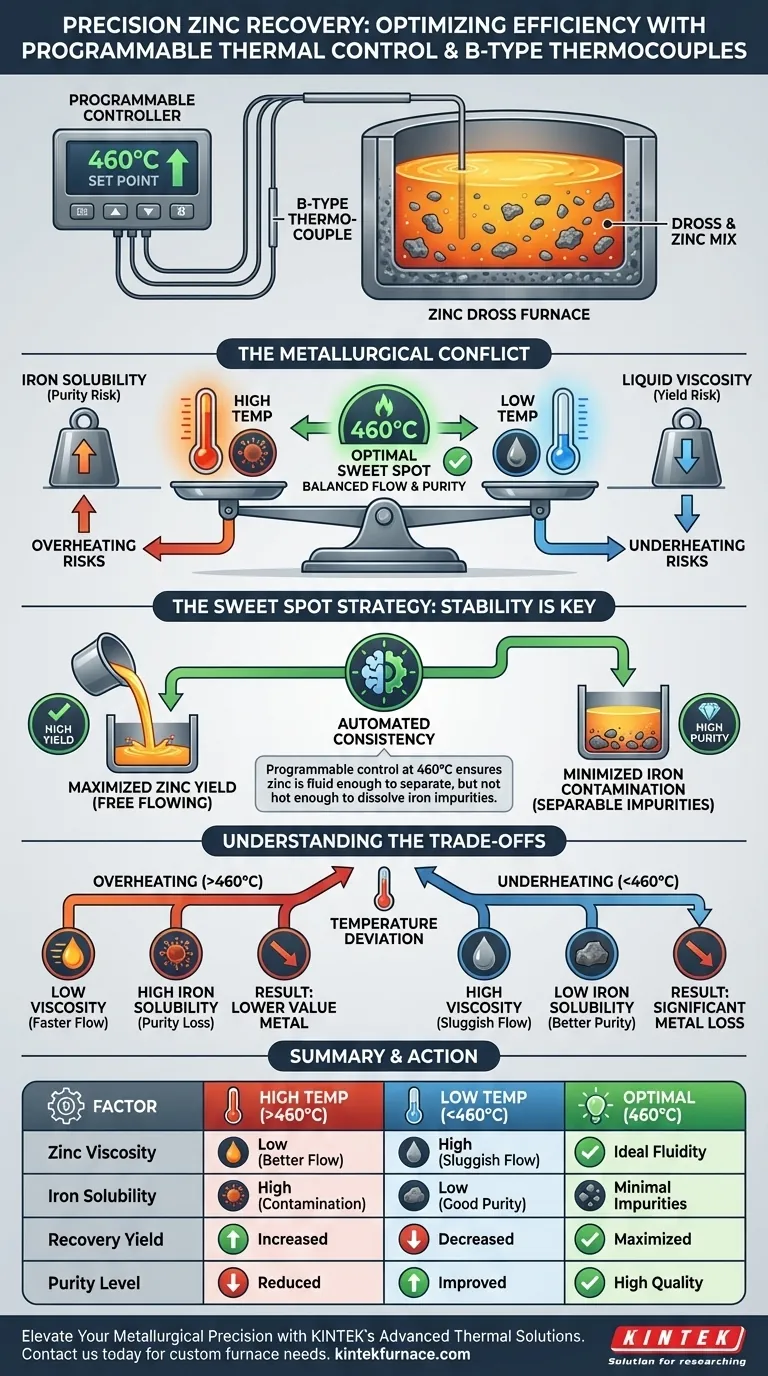

The integration of a programmable temperature controller with a B-type thermocouple directly enhances zinc recovery efficiency by enabling precise thermal regulation. By strictly maintaining optimal set points, such as 460°C, the system manipulates the physical properties of the molten metal. This precise control maximizes the volume of recovered zinc while significantly reducing iron contamination in the final product.

Core Takeaway: Temperature is the governing variable in zinc dross recovery that dictates the delicate balance between fluidity and purity. A programmable control system ensures the process stays in the narrow thermal window where zinc flows freely, but iron impurities remain precipitated and separable.

The Physics of Separation

To understand why this equipment configuration is effective, one must understand the metallurgical conflict at play during recovery. You are managing two opposing forces: iron solubility and liquid viscosity.

Controlling Iron Solubility

The primary reference highlights that temperature determines the saturated solubility of iron within liquid zinc.

As temperatures rise, the capacity for molten zinc to absorb iron increases. If the process runs too hot, iron impurities that should remain solid (and removable) dissolve back into the liquid.

Managing Viscosity and Fluidity

Conversely, the molten metal requires sufficient heat to maintain low viscosity.

If the temperature drops too low, the zinc becomes sluggish. This prevents it from flowing away from the dross (the waste material), trapping usable metal and reducing your overall yield.

The Role of Precision Instrumentation

The combination of a programmable controller and a B-type thermocouple solves the solubility-vs-viscosity conflict by enforcing stability.

The "Sweet Spot" Strategy

The system allows operators to target a specific "sweet spot," noted in the primary reference as 460°C.

At this exact temperature, the zinc is fluid enough to separate efficiently from the solid dross. However, it is not so hot that it forces the iron impurities into solution.

Automated Consistency

A programmable controller removes human error from the heating profile.

It constantly adjusts the energy input to maintain the set point, regardless of external fluctuations. This ensures that the recovery conditions remain constant throughout the entire batch processing time.

Understanding the Trade-offs

While precise control is essential, it is important to understand the risks of deviation in either direction.

The Risk of Overheating

If the controller is set incrementally too high, the viscosity improves, making the zinc flow faster.

However, the trade-off is purity. The resulting zinc liquid will contain higher levels of dissolved iron, lowering the market value of the recovered metal.

The Risk of Underheating

If the controller allows the temperature to dip below the optimal window, iron precipitation is maximized (good for purity).

However, the trade-off is yield. The zinc becomes too viscous to filter through the dross effectively, leading to significant metal loss in the waste stream.

Making the Right Choice for Your Goal

To apply this effectively, you must configure your programmable controller based on your specific quality targets.

- If your primary focus is Maximum Purity: Set the temperature at the lower end of the operational window (e.g., strictly 460°C or slightly below) to minimize iron solubility, accepting a slight reduction in flow speed.

- If your primary focus is Maximum Yield: Ensure the temperature never drops below the critical flow threshold, prioritizing viscosity to extract every drop of liquid zinc from the dross.

Success in zinc recovery relies not just on melting the metal, but on stabilizing the thermal environment where separation physics work in your favor.

Summary Table:

| Factor | Effect of High Temp (>460°C) | Effect of Low Temp (<460°C) | Optimal Control (460°C) |

|---|---|---|---|

| Zinc Viscosity | Low (Better Flow) | High (Sluggish Flow) | Ideal Fluidity |

| Iron Solubility | High (High Contamination) | Low (Good Purity) | Minimal Impurities |

| Recovery Yield | Increased | Decreased | Maximized |

| Purity Level | Reduced | Improved | High Quality |

Elevate Your Metallurgical Precision with KINTEK

Maximize your recovery yields and ensure peak material purity with KINTEK’s advanced thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers state-of-the-art Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet your unique lab and industrial requirements. Our high-temperature furnaces, equipped with precision programmable controllers, provide the stability needed for critical processes like zinc dross recovery.

Ready to optimize your thermal processing? Contact us today to discuss your custom furnace needs!

Visual Guide

References

- S. J. Zhang, Zhancheng Guo. Purification and Recovery of Hot-Dip Galvanizing Slag via Supergravity-Induced Cake-Mode Filtration. DOI: 10.3390/met14010100

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

People Also Ask

- What temperature range can MoSi2 heating elements operate in? Achieve High-Temp Precision with Expert Solutions

- What are the applications of silicon carbide and MoSi2 heating elements? Optimize Your High-Temp Processes

- What type of heating elements are commonly used in both tube and box furnaces? Explore Key Choices for High-Temp Labs

- What are the principles and characteristics of thermistors? Unlock Precision Temperature Sensing

- What factors should be considered when selecting a heating element? Ensure Optimal Performance and Longevity

- What is the unique design feature of W Type Silicon Carbide Heating Elements? Engineered for uniform heating in industrial furnaces

- What are the unique properties of silicon carbide heating elements? Key Benefits for High-Temp Performance

- What are the methods for producing molybdenum disilicide? Key Techniques for High-Temp Material Success