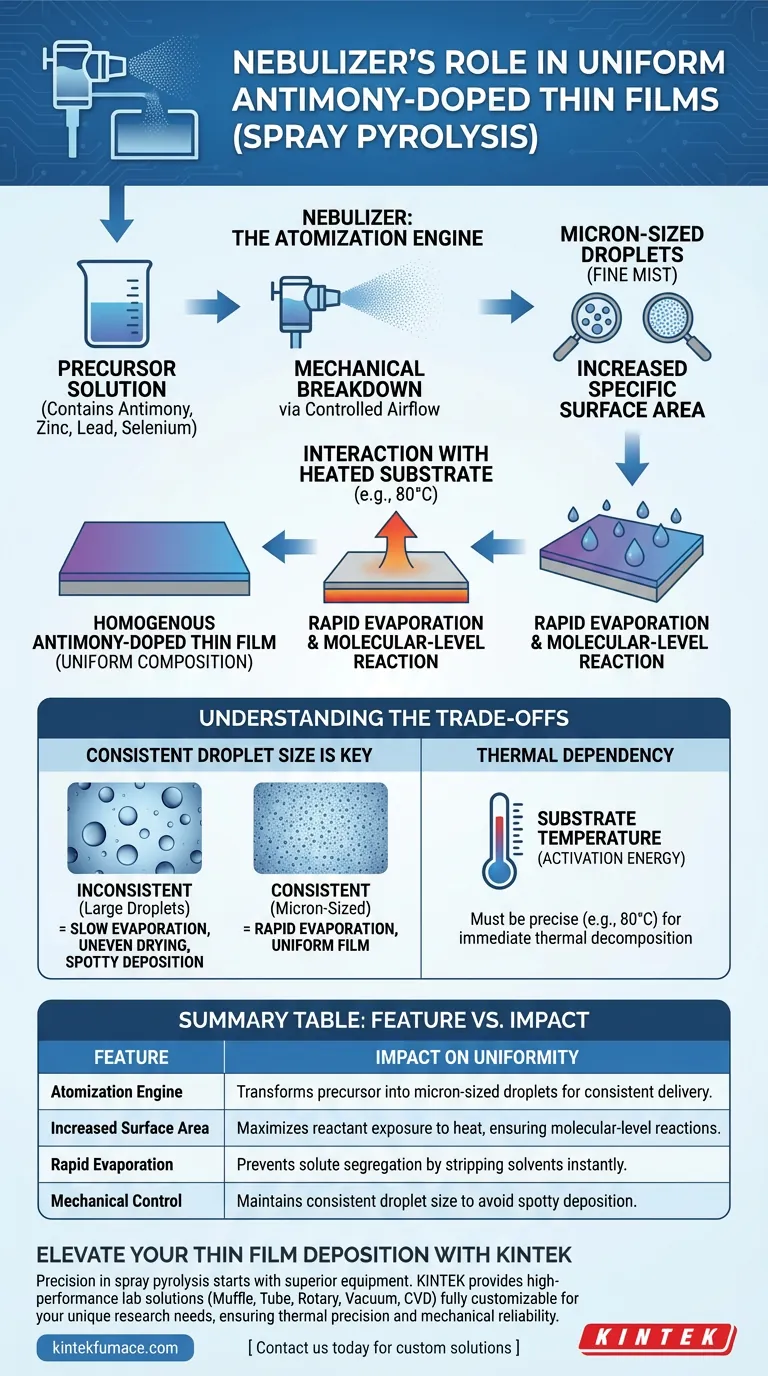

The nebulizer functions as the critical atomization engine in the spray pyrolysis process, strictly controlling the delivery of reactant solutions. By utilizing airflow to mechanically break down precursor solutions containing Antimony, Lead, Zinc, and Selenium, it transforms liquids into a fine mist of micron-sized droplets. This process creates the necessary physical conditions for rapid evaporation and reaction, which are directly responsible for the compositional uniformity of the final thin film.

By maximizing the specific surface area of the reactants through high-degree atomization, the nebulizer ensures reactions occur at the molecular level. This is the fundamental mechanism that prevents segregation and guarantees a homogenous Antimony-doped structure.

The Mechanics of Atomization

Breaking Down Precursor Solutions

The primary role of the nebulizer is to disrupt the bulk liquid state of the precursor solution.

Using controlled airflow, it fractures the solution into consistent, micron-sized droplets. This mechanical breakdown is essential for handling complex solutions containing dopants like Antimony alongside base elements such as Zinc or Lead.

Increasing Specific Surface Area

The transition from bulk liquid to micron-sized droplets drastically alters the physics of the reaction.

This atomization significantly increases the specific surface area of the reactants. A larger surface area ensures that a higher percentage of the precursor material is immediately exposed to the thermal environment required for processing.

Interaction with the Heated Substrate

Facilitating Rapid Evaporation

Once the nebulizer generates the mist, these droplets travel to the substrate, which is maintained at a specific temperature (e.g., 80°C).

Because the droplets are micron-sized, they undergo rapid evaporation upon contact. The controlled heating provided by the substrate platform aids this process, stripping away solvents quickly to leave behind the solute.

Enabling Molecular-Level Reaction

The uniformity of the film is determined at the moment of impact and decomposition.

The high surface area and rapid evaporation allow the chemical reactions to occur at a molecular level. This prevents the formation of large clusters and ensures that Antimony is evenly distributed throughout the ZnSe or PbSe lattice during nucleation and growth.

Understanding the Trade-offs

The Necessity of Consistent Droplet Size

While the nebulizer is powerful, its effectiveness relies entirely on the consistency of the atomization.

If the droplets are too large, the specific surface area decreases, leading to slower evaporation. This can result in uneven drying, spotty deposition, or incomplete chemical reactions that compromise the film's uniformity.

Thermal Dependency

The nebulizer cannot function effectively in isolation; it requires precise synchronization with the substrate temperature.

If the substrate does not provide sufficient activation energy, even perfect atomization will fail to produce a solid film. The thermal decomposition of the droplets relies on the substrate providing the necessary heat immediately upon contact.

Optimization for Film Quality

To achieve the best results with Antimony-doped thin films, you must balance the mechanical atomization with thermal control.

- If your primary focus is Compositional Uniformity: distinct attention must be paid to the nebulizer's airflow settings to ensure the smallest possible droplet size and maximum specific surface area.

- If your primary focus is Effective Nucleation: verify that the substrate platform maintains a precise temperature (e.g., 80°C) to provide the activation energy required for the atomized droplets to decompose.

Mastering the atomization process is the first and most crucial step in engineering high-quality, defect-free doped thin films.

Summary Table:

| Feature | Impact on Thin Film Uniformity |

|---|---|

| Atomization Engine | Transforms precursor into micron-sized droplets for consistent delivery. |

| Increased Surface Area | Maximizes reactant exposure to heat, ensuring molecular-level reactions. |

| Rapid Evaporation | Prevents solute segregation by stripping solvents instantly upon contact. |

| Mechanical Control | Maintains consistent droplet size to avoid spotty deposition or clusters. |

Elevate Your Thin Film Deposition with KINTEK

Precision in spray pyrolysis starts with superior equipment. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance lab solutions including Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique research needs.

Whether you are optimizing Antimony-doped thin films or developing advanced semiconductors, our systems ensure the thermal precision and mechanical reliability required for defect-free results. Contact us today to discuss your custom furnace solution and see how KINTEK can enhance your laboratory’s efficiency and output.

Visual Guide

References

- Ikechukwu Christian Nworie, B. Ojobo. Comparative Assessment of Optical and Solid-State Characteristics in Antimony-Doped Chalcogenide Thin Films of ZnSe and PbSe to Boost Photovoltaic Performance in Solar Cells. DOI: 10.62292/njp.v33i1.2024.202

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What are the different types of CVD systems? Find the Perfect Fit for Your Lab's Needs

- How does automation and intelligent control enhance CVD furnace operations? Boost Efficiency and Quality in Thin Film Deposition

- What role does an industrial-grade CVD system play in Ni-Based Superalloys? Enhancing Durability via Precise Coating

- What is an example of a CVD process? Coating Carbon Nanotubes for Advanced Electronics

- How does a CVD system facilitate in-situ graphene synthesis? High-Quality Coatings for Flexible Electronics

- What functions do high-purity graphite crucibles and mandrels serve in the CVD of ZnS? Essential Components for Success

- What role does a Chemical Vapor Deposition (CVD) system play in 2D material synthesis? Master Scalable Material Growth

- How does precise gas flow control affect Cr2O3 thin films? Mastering Stoichiometry and Crystal Structure