In short, vacuum tube furnaces achieve energy efficiency by fundamentally altering the physics of heat transfer. They combine advanced insulation to contain heat, intelligent control systems to use energy precisely, and a vacuum environment that nearly eliminates heat loss from gas convection, making them exceptionally effective at delivering thermal energy only where it is needed.

The primary challenge in any furnace is preventing heat from escaping. A vacuum tube furnace excels by creating an environment where one of the main culprits of heat loss—air—is removed, forcing heat to remain concentrated on the target material.

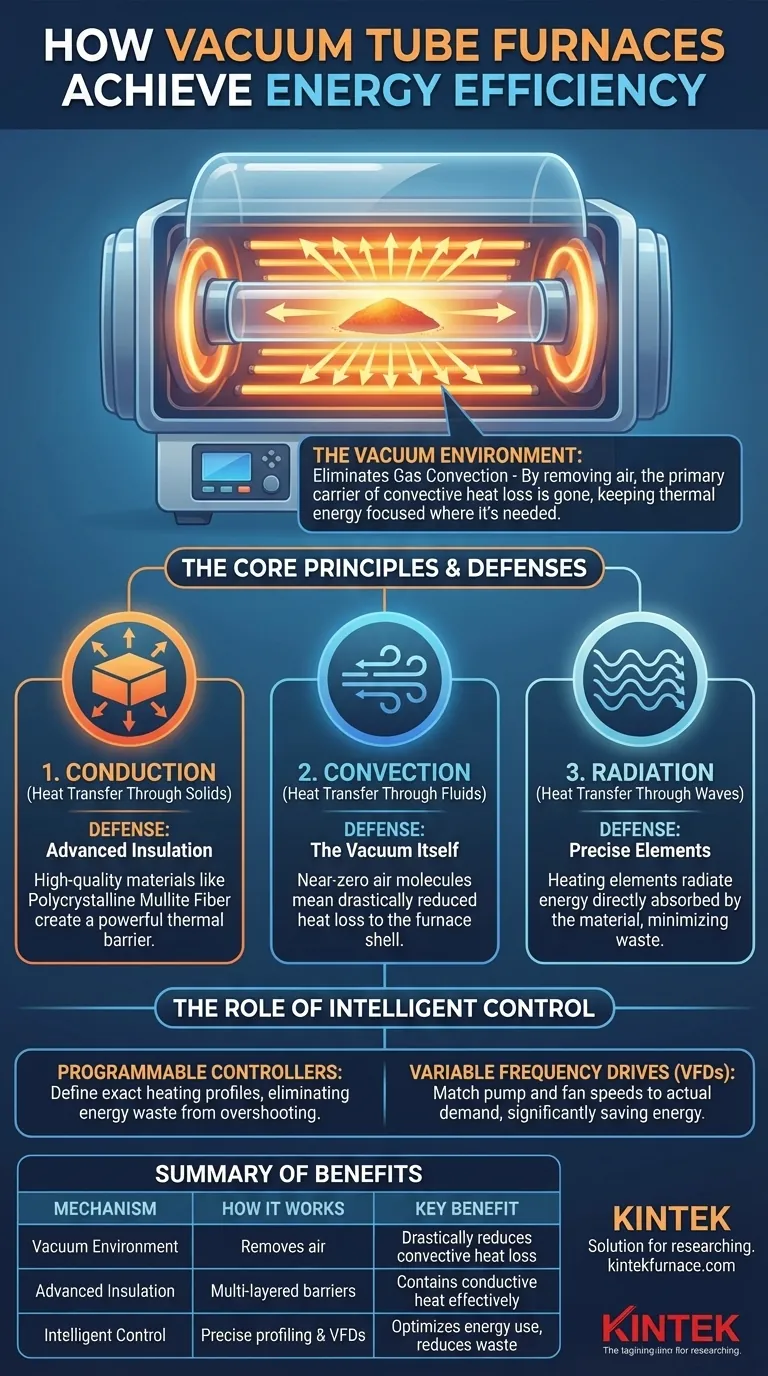

The Core Principles of Thermal Efficiency

To understand a furnace's efficiency, you must first understand its enemies. Heat energy always seeks to move from a hot area to a cold one through three primary mechanisms. An efficient furnace is one that builds the best defenses against them.

Conduction: Heat Transfer Through Solids

Conduction is heat moving directly through a material. In a furnace, this means heat trying to escape through the furnace walls, lid, and other solid components.

Convection: Heat Transfer Through Fluids (Gases/Liquids)

Convection is heat carried by the movement of fluids, like air. Hot air inside a conventional furnace rises and transfers heat to the furnace shell, where it is lost to the outside environment. This is often the single largest source of energy loss.

Radiation: Heat Transfer Through Waves

Radiation is heat traveling as electromagnetic waves. This is how the sun heats the Earth. Inside a furnace, heating elements radiate energy that is absorbed by the material being processed.

How Vacuum Furnaces Minimize Heat Loss

A vacuum furnace's design is a systematic counter-attack against these forms of heat loss, with its most powerful weapon being the vacuum itself.

The Vacuum Itself: Eliminating Convection

By pumping out nearly all the air, a vacuum environment removes the primary medium for convective heat transfer. With very few gas molecules left to move around and carry energy away, heat loss to the furnace shell is drastically reduced.

This stands in contrast to an atmosphere furnace, which uses inert gases to prevent oxidation but still suffers from significant convective heat loss. A vacuum is a far superior insulator than any gas.

Advanced Insulation: Containing Conductive Heat

To combat conduction, modern vacuum furnaces are built with multi-layered defenses.

High-quality insulation, such as polycrystalline mullite fiber, lines the heating chamber. This material has extremely low thermal conductivity, acting as a powerful barrier that keeps heat from reaching the furnace walls.

Many designs also feature a double-layer furnace shell. This creates an air gap between the inner and outer walls, which is often fan-cooled. This "air insulation" provides a final buffer, ensuring the outer surface of the furnace remains cool and energy is kept inside.

Regenerative Systems: Recycling Waste Heat

High-end systems often include regenerative cooling systems. Instead of simply venting the heat removed during the cooling cycle, this technology captures it and can use it to pre-heat subsequent cycles or for other plant processes, dramatically improving overall energy utilization.

The Role of Intelligent Control

Efficiency isn't just about preventing loss; it's also about using energy intelligently in the first place.

Programmable Controllers for Precision

Modern furnaces use programmable controllers that allow operators to define exact heating and cooling profiles. This ensures the furnace uses only the energy required to reach and hold a specific temperature for a precise duration.

This precision eliminates the waste associated with overshooting temperature targets or holding a process at peak temperature for longer than necessary.

Variable Frequency Drives (VFDs)

The vacuum pumps and cooling fans are significant energy consumers. Variable Frequency Drives (VFDs) match the motor speed of these components to the actual demand of the process.

For example, once a deep vacuum is achieved, the pump doesn't need to run at full power. A VFD will slow it down, maintaining the vacuum with minimal energy draw and saving substantial operational costs.

Understanding the Trade-offs

While highly efficient, vacuum furnaces are not the universal solution. Objectivity requires acknowledging their limitations.

Higher Initial Investment

The complexity of the vacuum system, including robust chamber construction and high-performance pumps, means vacuum furnaces typically have a higher upfront cost than their atmospheric counterparts.

Energy for Pumping

Creating a vacuum is an energy-intensive process. While VFDs mitigate this, the energy consumed by the pumps is a real operational cost that must be factored into the total energy equation. The net benefit is almost always positive, but it is not a zero-cost feature.

Cycle Time Considerations

The time required to pump the chamber down to the target vacuum level (pump-down time) adds to the total cycle time. For some high-throughput applications, this could be a limiting factor compared to simpler, non-vacuum systems.

Making the Right Choice for Your Process

Your choice of furnace technology should be driven by the specific demands of your thermal process.

- If your primary focus is process purity and maximum efficiency: A vacuum furnace is the superior choice, as it eliminates atmospheric contamination and convective heat loss.

- If your primary focus is minimizing operational costs over the long term: A modern vacuum furnace with VFDs and regenerative systems will likely deliver the lowest total cost of ownership.

- If your primary focus is high throughput on a limited budget: A simpler atmosphere furnace may be more suitable, provided that its lower thermal efficiency and potential for atmospheric interaction are acceptable for your process.

Ultimately, understanding the principles of thermal efficiency empowers you to select the right tool that aligns with both your technical requirements and financial goals.

Summary Table:

| Mechanism | How Vacuum Furnace Addresses It | Key Benefit |

|---|---|---|

| Convection | Removes air to eliminate gas-based heat transfer | Drastically reduces energy loss |

| Conduction | Uses advanced insulation like mullite fiber | Contains heat within the chamber |

| Radiation | Employs precise heating elements | Directs energy to target material |

| Control Systems | Implements programmable controllers and VFDs | Optimizes energy use and reduces waste |

| Regenerative Cooling | Captures and reuses waste heat | Improves overall energy efficiency |

Ready to enhance your lab's energy efficiency with tailored solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace systems, including Vacuum & Atmosphere Furnaces, Muffle, Tube, Rotary Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs, helping you save on operational costs and improve performance. Contact us today to discuss how our solutions can benefit your specific processes!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab