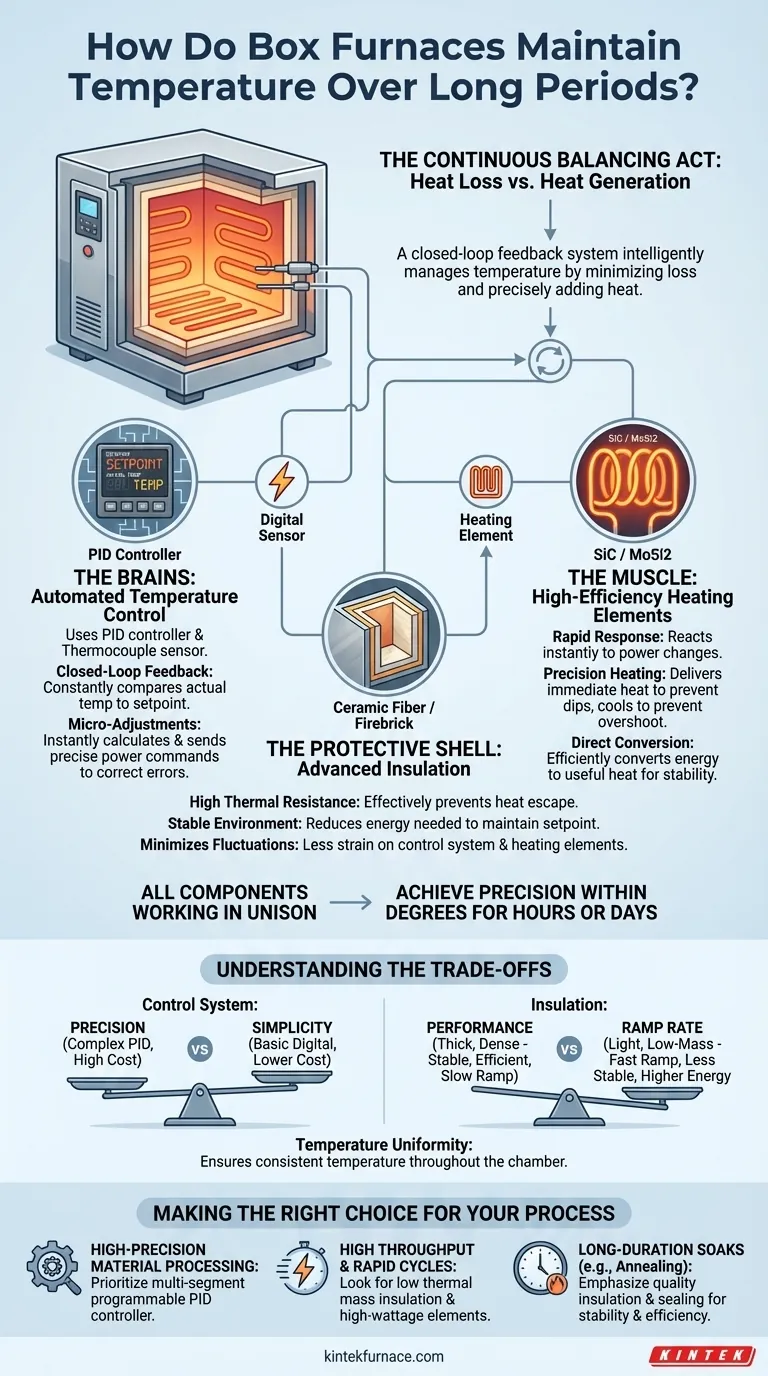

At its core, a box furnace maintains a stable temperature over long periods by creating a highly precise and continuous balancing act between heat loss and heat generation. This is achieved through the integration of three key systems: an automated digital controller that acts as the brain, high-efficiency heating elements that provide the power, and advanced insulation that minimizes the heat escaping into the environment.

The challenge of temperature stability is not just about producing heat, but about intelligently managing it. A box furnace excels by using a closed-loop feedback system to constantly measure the internal temperature and make micro-adjustments to the power output, ensuring the heat being added perfectly compensates for the heat being lost.

The Core Components of Temperature Stability

To understand how a furnace achieves precision within just a few degrees for hours or days, we must look at the three interdependent components that work in unison. Each plays a distinct and critical role.

Automated Temperature Control: The Brains of the Operation

The heart of temperature stability is the automated control system, which typically uses a PID (Proportional-Integral-Derivative) controller. Think of this like a sophisticated cruise control system for temperature.

A sensor, usually a thermocouple, constantly measures the actual temperature inside the chamber and sends this information back to the controller.

The controller then compares the actual temperature to your desired setpoint. It instantly calculates the difference (the "error") and determines precisely how much power to send to the heating elements to correct it.

This closed-loop feedback process happens many times per second, preventing the temperature from drifting by making constant, tiny adjustments rather than large, infrequent ones.

High-Efficiency Heating Elements: The Muscle

The controller's commands are carried out by the heating elements. Modern furnaces use materials like silicon carbide (SiC) or molybdenum disilicide (MoSi2) that can respond almost instantly to changes in power.

This responsiveness is crucial. When the controller demands a slight increase in heat, these elements can deliver it immediately, preventing a temperature dip. When the controller cuts power, they cool just enough to prevent overshooting the target.

The efficiency of these elements ensures that the energy is converted directly into useful heat within the chamber, enabling the fine control needed for stability.

Advanced Insulation: The Protective Shell

Finally, the furnace chamber is lined with high-performance insulation. Modern designs often use low thermal mass ceramic fiber or firebrick.

The primary job of insulation is to have high thermal resistance, meaning it is very effective at preventing heat from escaping the chamber. This reduces the overall energy required to maintain the setpoint.

By minimizing heat loss, the insulation creates a more stable environment. The control system doesn't have to work as hard, and the heating elements can operate at a lower, more consistent output, which dramatically reduces temperature fluctuations.

Understanding the Trade-offs

Achieving perfect stability involves balancing competing factors. Understanding these trade-offs is key to selecting the right equipment and diagnosing issues.

Control System Precision vs. Simplicity

A sophisticated, programmable PID controller offers the highest degree of precision, allowing a user to "tune" its responsiveness for a specific process. However, a simpler digital or manual controller may be sufficient and more cost-effective for applications where minor fluctuations are acceptable.

Insulation Performance vs. Ramp Rate

A furnace with very thick, dense insulation will be extremely stable once at temperature and highly energy-efficient for long soaks. However, that same thermal mass means it will take much longer to heat up and cool down (a slow ramp rate).

Conversely, a furnace with lighter, low-mass insulation will heat up very quickly but may be slightly less stable and consume more energy during extended holds.

Temperature Uniformity

The references rightly point to temperature uniformity—ensuring the temperature is the same in all corners of the chamber. If a furnace has hot and cold spots, a single thermocouple may report a stable average while your parts are experiencing different temperatures, compromising process results.

Making the Right Choice for Your Process

Your specific application determines which of these factors is most important.

- If your primary focus is high-precision material processing: Prioritize a furnace with a multi-segment programmable PID controller for exacting control over the temperature profile.

- If your primary focus is high throughput and rapid cycles: Look for a furnace with low thermal mass insulation and high-wattage heating elements for fast ramp rates.

- If your primary focus is long-duration soaks (e.g., annealing): Emphasize the quality of the insulation and chamber sealing to ensure stability and energy efficiency over many hours or days.

Understanding how these systems work together empowers you to control your thermal process with confidence and precision.

Summary Table:

| Component | Role in Temperature Stability |

|---|---|

| Automated Temperature Control | Uses PID controllers and thermocouples for real-time adjustments via closed-loop feedback. |

| High-Efficiency Heating Elements | Provide instant heat response with materials like silicon carbide or molybdenum disilicide. |

| Advanced Insulation | Minimizes heat loss with high thermal resistance materials like ceramic fiber or firebrick. |

Need a reliable high-temperature furnace for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to deliver advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet your unique experimental requirements for long-term temperature stability. Contact us today to discuss how our furnaces can enhance your process efficiency and precision!

Visual Guide

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What role does a Muffle Furnace play in 1100°C oxidation experiments? Precision Thermal Control for Coatings

- Why is a high-temperature muffle furnace typically selected for annealing? Achieve Optimal Ceramic Performance

- What is the function of a muffle furnace in LSCF modification? Achieve Precise Thermal Foundation for Advanced Ceramics

- How is an industrial-grade ashing furnace utilized in 3D-printed bioactive glass? Master Debinding & Sintering