In the demanding environment of a laboratory, the exceptionally low thermal expansion of quartz is critical because it prevents the material from shattering or deforming when subjected to rapid and extreme temperature changes. This property, known as high thermal shock resistance, is the primary reason quartz is trusted for the integrity and safety of experiments involving high-heat applications, such as in tube furnaces or over a direct flame.

The importance of quartz's low thermal expansion goes beyond simple durability. It is the fundamental property that ensures dimensional stability and structural integrity during intense heating and cooling, directly translating to more reliable experimental results, safer lab conditions, and a longer lifespan for expensive equipment.

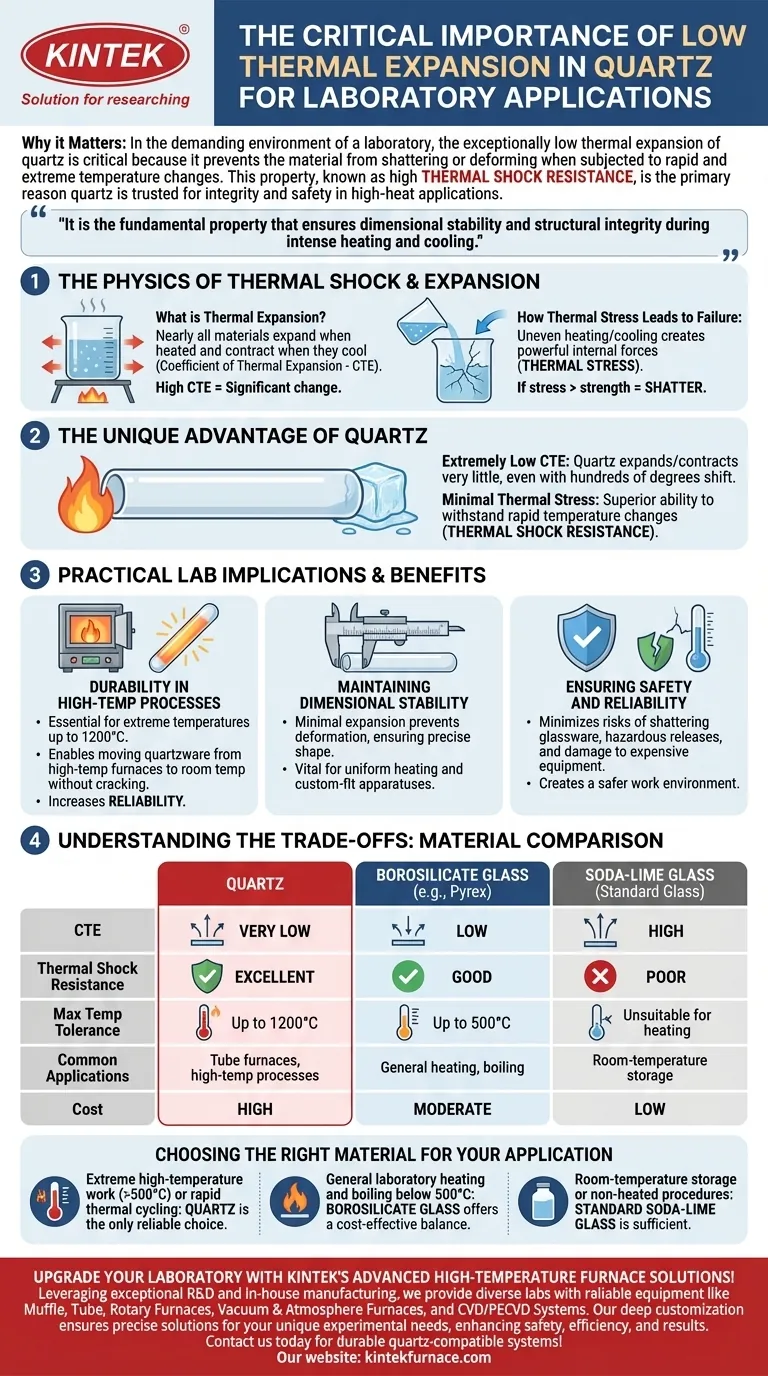

The Physics of Thermal Shock

To understand why quartz is so valuable, we must first understand the destructive force it resists: thermal shock.

What is Thermal Expansion?

Nearly all materials expand when heated and contract when they cool. The rate at which a material changes its size with temperature is its coefficient ofthermal expansion (CTE).

A material with a high CTE will expand and contract significantly, even with moderate temperature changes.

How Thermal Stress Leads to Failure

When a piece of glassware is heated or cooled unevenly—for example, by pouring a cold liquid into a hot beaker—different parts of the material try to expand or contract at different rates.

This conflict creates powerful internal forces known as thermal stress. If this stress exceeds the material's inherent strength, it will crack or shatter.

The Unique Advantage of Quartz

Fused quartz has an extremely low coefficient of thermal expansion. It expands and contracts very little, even when facing rapid temperature shifts of hundreds of degrees.

Because it barely changes in size, minimal thermal stress builds up within the material. This superior ability to withstand rapid temperature changes without cracking is its signature thermal shock resistance.

Practical Implications in the Laboratory

This physical property has direct, tangible benefits in a working lab environment.

Durability in High-Temperature Processes

Quartzware is essential for applications involving extreme temperatures, often up to 1200°C. You can move a quartz tube from a high-temperature furnace to room temperature without it cracking.

This durability increases the reliability of experiments and reduces equipment failure, which is especially critical in automated or long-duration processes.

Maintaining Dimensional Stability

Because quartz does not significantly expand or deform when heated, it maintains its precise shape.

This is vital in systems like tube furnaces, where uniform and consistent heating across a sample is required. It also ensures that custom-fit apparatuses continue to fit perfectly at operating temperature.

Ensuring Safety and Reliability

A shattering piece of glassware can ruin a critical experiment, release hazardous materials, and damage expensive equipment like the inside of a furnace.

The reliability of quartz minimizes these risks, creating a safer work environment and preventing the loss of valuable time and resources due to material failure.

Understanding the Trade-offs: Quartz vs. Other Glassware

Quartz is a superior material, but its properties must be weighed against cost and the specific demands of an application.

Borosilicate Glass (e.g., Pyrex)

This is the most common type of lab glassware. Borosilicate has a CTE that is much lower than standard glass, but still significantly higher than quartz.

It is an excellent, cost-effective choice for general heating and boiling but cannot withstand the extreme thermal shock that quartz can. It may crack under the rapid temperature cycling common in furnace work.

Soda-Lime Glass (Standard Glass)

This is the glass used for windows and drinkware. It has a very high CTE and is extremely susceptible to thermal shock.

It is completely unsuitable for serious laboratory heating and should be restricted to room-temperature applications like storage bottles or titration flasks.

The Cost Factor

The primary trade-off is cost. Fused quartz is considerably more expensive to manufacture than borosilicate glass. Its use is therefore justified when its superior thermal performance is a non-negotiable requirement for the experiment's success and safety.

Choosing the Right Material for Your Application

Your choice of glassware directly impacts the safety, cost, and success of your work. Use the specific demands of your task to guide your decision.

- If your primary focus is extreme high-temperature work (>500°C) or rapid thermal cycling: Quartz is the only reliable choice due to its unmatched thermal shock resistance.

- If your primary focus is general laboratory heating and boiling below 500°C: Borosilicate glass offers a cost-effective balance of thermal resistance and durability for most standard applications.

- If your primary focus is room-temperature storage or non-heated procedures: Standard soda-lime glass is sufficient and represents the most economical option.

Understanding the thermal properties of your materials is fundamental to designing safe, reliable, and repeatable experiments.

Summary Table:

| Property | Quartz | Borosilicate Glass | Soda-Lime Glass |

|---|---|---|---|

| Coefficient of Thermal Expansion (CTE) | Very Low | Low | High |

| Thermal Shock Resistance | Excellent | Good | Poor |

| Max Temperature Tolerance | Up to 1200°C | Up to 500°C | Unsuitable for heating |

| Common Applications | Tube furnaces, high-temperature processes | General heating, boiling | Room-temperature storage |

| Cost | High | Moderate | Low |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, enhancing safety, efficiency, and results. Contact us today to discuss how we can support your high-heat applications with durable quartz-compatible systems!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety