At its core, induction heating is a strategic investment because it fundamentally changes how energy is delivered to a part. Instead of slowly heating a component from the outside-in using a furnace, induction generates rapid, precise, and controllable heat directly within the material itself. This shift delivers a powerful combination of higher energy efficiency, superior process control, increased speed, and a safer, cleaner operating environment, directly impacting a manufacturer's bottom line and competitive standing.

Induction heating moves beyond being a simple equipment upgrade; it is a strategic shift toward a more controllable, efficient, and automated manufacturing process. It's an investment in process precision that unlocks significant downstream benefits in cost, quality, and throughput.

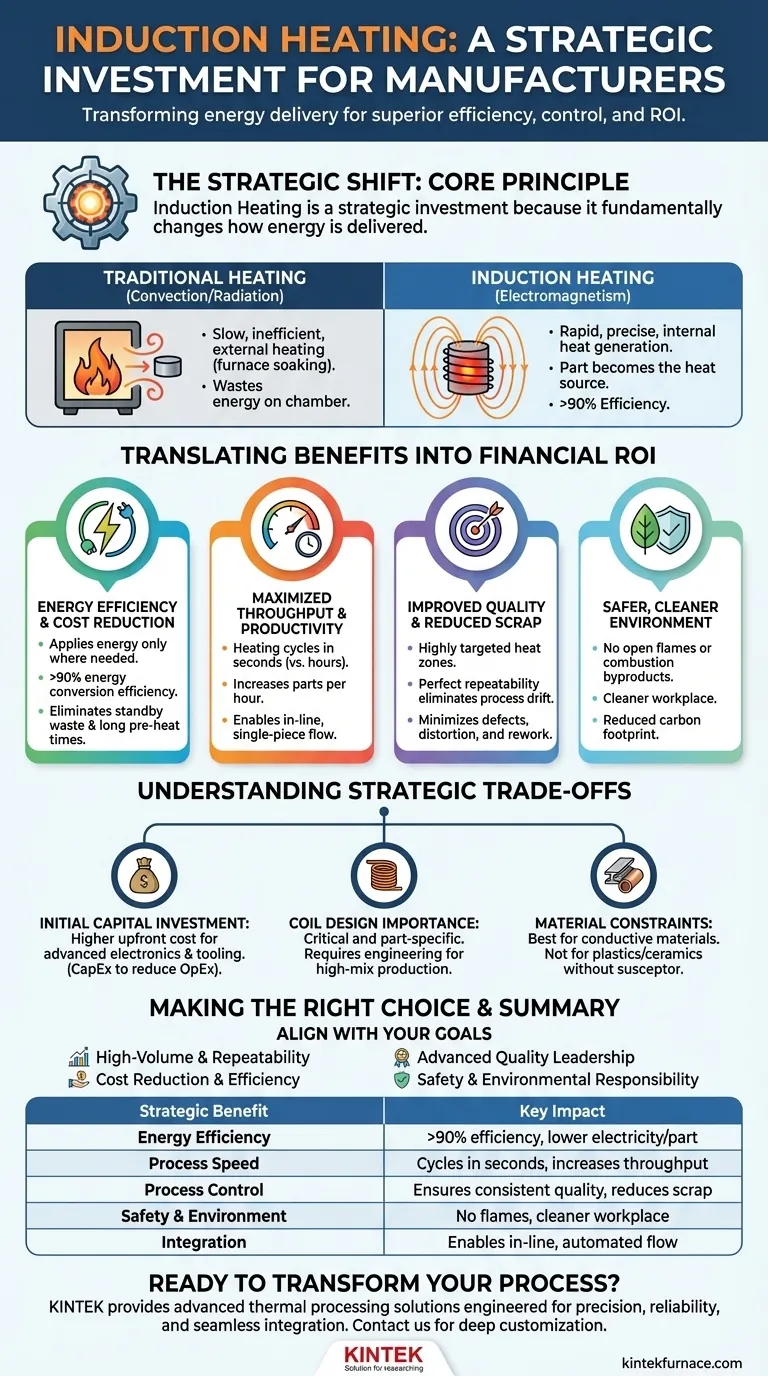

How Induction Transforms the Heating Process

To understand the strategic value, you must first understand why induction is fundamentally different from traditional heating methods like gas-fired furnaces or resistance ovens.

From Convection to Electromagnetism

Traditional furnaces operate on convection and radiation, heating the entire chamber and the air inside it to slowly transfer thermal energy to the workpiece. This process is slow, inefficient, and difficult to control with precision.

Induction heating uses an alternating electromagnetic field to induce electrical currents (eddy currents) directly within the conductive workpiece. The material's resistance to these currents generates instantaneous, localized heat.

The Part Becomes the Heat Source

With induction, the part itself becomes the heating element. Heat is generated inside the material, not applied to its surface.

This allows for incredibly rapid heating cycles—often measured in seconds rather than the minutes or hours required for furnace soaking.

Instantaneous and Repeatable Control

An induction system can be turned on and off instantly, with power levels adjusted in real-time. This provides an unparalleled level of control over the heating cycle.

Because the process is governed by electrical parameters, it is perfectly repeatable. The 1,000th part receives the exact same thermal treatment as the first, eliminating the process drift common in traditional furnaces.

Translating Technical Benefits into Financial ROI

A strategic investment must deliver a clear return. Induction heating impacts multiple financial levers simultaneously.

Driving Down Energy Costs

Furnaces waste enormous amounts of energy heating the chamber walls, insulation, and surrounding air. They often must be kept running between cycles to avoid long pre-heat times.

Induction applies energy only where and when it's needed, with energy conversion efficiencies often exceeding 90%. This drastically reduces electricity consumption per part and eliminates standby energy waste.

Maximizing Throughput and Productivity

The speed of induction heating directly increases the number of parts processed per hour. This higher throughput can de-bottleneck a production line and increase overall plant capacity without physical expansion.

Fast cycle times and the potential for in-line, single-piece flow also reduce work-in-progress (WIP) inventory compared to batch processing in large ovens.

Improving Quality and Reducing Scrap

The precision of induction allows for highly targeted heat zones. You can harden just the tip of a gear tooth or braze a specific joint without affecting the rest of the component.

This precision, combined with perfect repeatability, minimizes defects, distortion, and material degradation. The result is a dramatic reduction in costly scrap, rework, and warranty claims.

Understanding the Strategic Trade-offs

No technology is a universal solution. An objective evaluation requires acknowledging the specific considerations for induction heating.

The Initial Capital Investment

Induction heating systems typically carry a higher initial purchase price than some conventional ovens or torch setups. The investment is in advanced power electronics and custom tooling.

This must be evaluated as a capital expenditure (CapEx) that reduces long-term operational expenditures (OpEx) through lower energy bills, reduced labor, less scrap, and higher throughput.

The Importance of Coil Design

The induction coil, which creates the magnetic field, is the heart of the system. Its design is critical and is often tailored to the specific geometry of the part being heated.

This means a single coil may not be suitable for a wide variety of parts. Operations with high-mix, low-volume production must account for the engineering and cost of multiple coil designs.

Material and Process Constraints

Induction works best on electrically conductive materials like steel, copper, and aluminum. It is not suitable for heating non-conductive materials like plastics or ceramics unless a conductive susceptor is used. The process is also optimized for defined geometries where a coil can be efficiently coupled to the part.

Making the Right Choice for Your Operation

The decision to invest in induction heating should be aligned with your specific strategic goals.

- If your primary focus is high-volume production and repeatability: Induction is an ideal choice for its speed, consistent quality, and ease of integration into automated lines.

- If your primary focus is cost reduction and efficiency: The significant energy savings and drastic reduction in scrap and rework provide a clear and often rapid return on investment.

- If your primary focus is advanced manufacturing and quality leadership: The unparalleled process control enables complex heat treatments, improves part performance, and serves as a mark of technical excellence.

- If your primary focus is safety and environmental responsibility: Induction heating eliminates open flames and combustion byproducts, creating a safer, cleaner workplace and reducing your carbon footprint.

Investing in induction heating is an investment in a more controlled, predictable, and efficient manufacturing future.

Summary Table:

| Strategic Benefit | Key Impact |

|---|---|

| Energy Efficiency | >90% efficiency, reduces electricity consumption per part |

| Process Speed | Heating cycles in seconds vs. hours, increases throughput |

| Process Control & Repeatability | Eliminates process drift, ensures consistent quality, reduces scrap |

| Safety & Environment | No open flames or combustion byproducts, cleaner workplace |

| Integration & Automation | Enables in-line, single-piece flow for automated production lines |

Ready to Transform Your Manufacturing Process?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides advanced thermal processing solutions for manufacturers seeking a strategic edge. Our induction heating systems are engineered for precision, reliability, and seamless integration to deliver the efficiency, quality, and ROI detailed above.

Let's discuss how our deep customization capabilities can precisely meet your unique production requirements.

Contact KINTEK today to schedule a consultation and discover the strategic value we can bring to your operation.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Induction Melting Furnace

People Also Ask

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability

- What is the operating temperature of SiC? Unlock Reliable Performance Up to 1600°C

- What heating elements are used in high-temperature tube furnaces? Discover SiC and MoSi2 for Extreme Heat