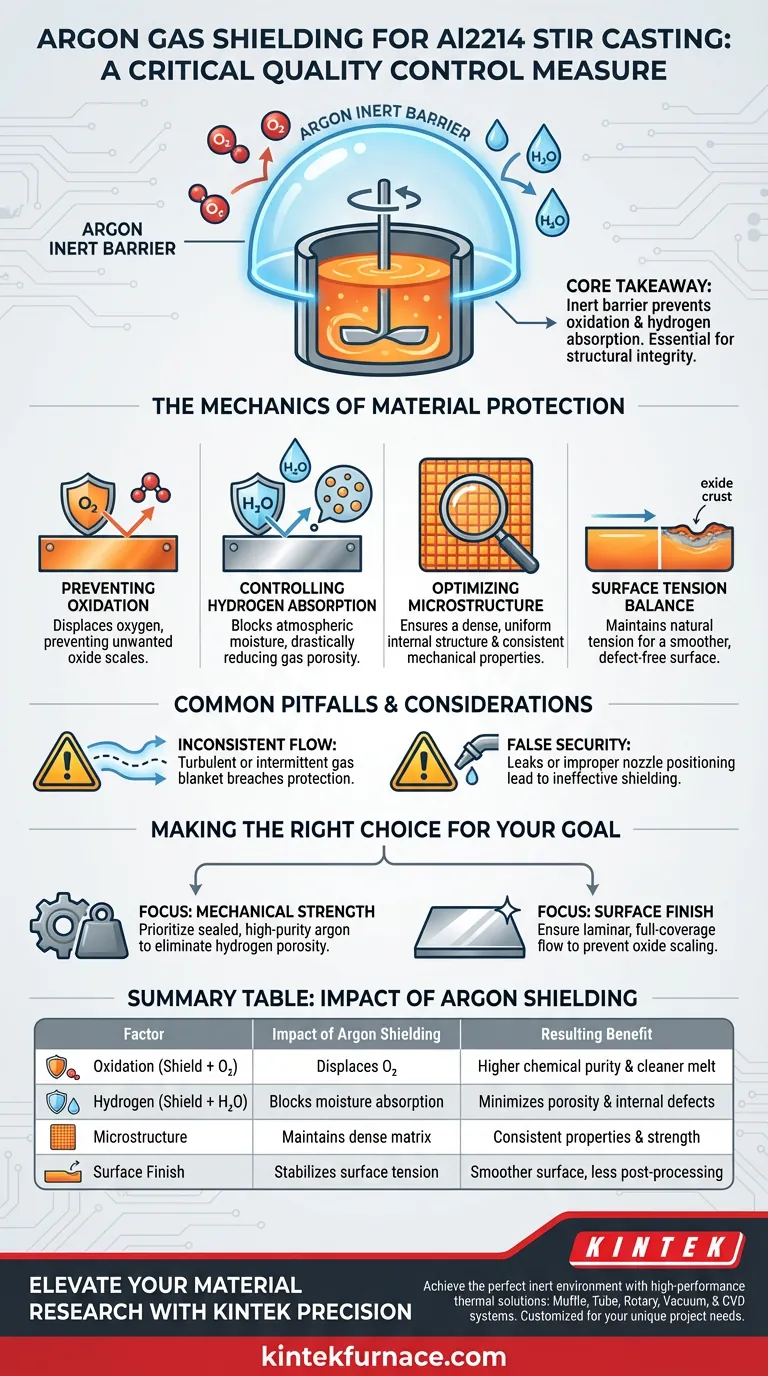

The implementation of an argon gas shielding environment is strictly necessary to create an inert barrier between the molten Al2214 alloy and the surrounding atmosphere. This protective layer is the primary mechanism for preventing the molten metal from reacting with air, which safeguards the material against oxidation and hydrogen absorption.

Core Takeaway Molten aluminum is highly reactive; without an inert barrier, it rapidly degrades. Argon shielding is not merely a precaution but a critical quality control measure that minimizes porosity and ensures the structural integrity of the final composite material.

The Mechanics of Material Protection

Preventing Oxidation

When aluminum alloys like Al2214 are melted, they have a high affinity for oxygen. Without a protective shield, the high-temperature molten pool reacts immediately with oxygen in the air.

This reaction forms unwanted oxide scales on the surface and within the melt. By displacing the air with argon, you eliminate the reactants required for these oxides to form, maintaining the chemical purity of the alloy.

Controlling Hydrogen Absorption

Atmospheric moisture is a significant threat to aluminum casting. Water vapor in the air reacts with molten aluminum to release hydrogen gas, which is then absorbed into the liquid metal.

As the metal creates a solid composite, this trapped hydrogen precipitates out, creating gas bubbles known as porosity. An argon environment creates a dry, inert zone that blocks moisture, drastically reducing the risk of porosity in the solidified composite.

Optimizing Microstructure

The quality of the final composite relies on a dense, uniform internal structure. The presence of oxides or gas pores disrupts the material's matrix, creating weak points that lead to mechanical failure.

By maintaining an inert atmosphere, you ensure a high-quality microstructure. This creates a foundation for consistent mechanical properties across the entire production batch.

Surface Tension Balance

Beyond chemical reactions, the atmosphere affects the physical behavior of the melt. Introducing an inert gas helps maintain the natural surface tension balance of the molten pool.

This stability prevents surface irregularities caused by oxidation films. The result is a smoother, defect-free processed surface that requires less post-processing.

Common Pitfalls and Considerations

The Risk of Inconsistent Flow

Simply having argon gas lines is not enough; the flow must be consistent and effectively distributed. If the shielding is intermittent or turbulence disrupts the gas blanket, oxygen can breach the protective layer.

False Security

Operators often assume that "turning on the gas" guarantees protection. However, leaks in the delivery system or improper nozzle positioning can render the shielding ineffective. Partial shielding can sometimes be as detrimental as no shielding if it leads to undetected, localized defects.

Making the Right Choice for Your Goal

To maximize the quality of your Al2214 composites, align your shielding strategy with your specific production targets:

- If your primary focus is mechanical strength: Prioritize a sealed, high-purity argon environment to eliminate hydrogen porosity, which is the main cause of structural weakness.

- If your primary focus is surface finish: Ensure the argon flow is laminar and covers the entire melt pool to prevent oxide scaling and maintain surface tension.

Ultimately, the precision of your argon shielding correlates directly to the density and reliability of your final composite product.

Summary Table:

| Factor | Impact of Argon Shielding | Resulting Benefit |

|---|---|---|

| Oxidation | Displaces oxygen to prevent oxide scale formation | Higher chemical purity and cleaner melt |

| Hydrogen | Blocks atmospheric moisture absorption | Minimizes gas porosity and internal defects |

| Microstructure | Maintains a dense, uniform material matrix | Consistent mechanical properties & strength |

| Surface Finish | Stabilizes surface tension of the molten pool | Smoother surface with less post-processing |

Elevate Your Material Research with KINTEK Precision

Achieving the perfect inert environment for Al2214 composite production requires equipment engineered for reliability. At KINTEK, we specialize in high-performance thermal solutions including Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which can be customized to your specific gas-shielding and atmospheric requirements.

Our expert R&D and manufacturing teams are dedicated to providing lab high-temp furnaces that ensure the structural integrity and density of your advanced materials. Don't let oxidation or porosity compromise your results—contact KINTEK today to discuss your unique project needs and discover the value of precision engineering.

Visual Guide

References

- Revanna Kambaiah, Anteneh Wogasso Wodajo. Mechanical‐wear behavior and microstructure analysis of Al2214 alloy with <scp>B<sub>4</sub>C</scp> and graphite particles hybrid composites. DOI: 10.1002/eng2.12876

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What precious metals can be melted in induction furnaces? Efficient, Clean Melting for Gold, Silver, and Platinum Group Metals

- Why are argon (Ar) and sulfur hexafluoride (SF6) introduced during magnesium alloy melting? Protect Your Melt Quality

- What role does a vacuum induction furnace with a water-cooled copper cold crucible play in melting Ti-33Mo-0.2C alloy?

- Why is stainless steel smelted in a vacuum induction melting furnace? Achieve Unmatched Purity and Performance

- What role does a vacuum arc melting furnace with a non-consumable electrode play? Key to CuAlMn Shape Memory Alloys

- How are current and voltage managed in the arc furnace process? Optimize Melting Efficiency and Stability

- What principle does an induction heater circuit operate on? Discover Efficient, Contactless Heating

- What are the technical advantages of using a thin-wall with wide slits crucible? Boost Induction Skull Melting Efficiency