In diamond synthesis using MPCVD, power density is the critical control parameter that directly dictates the quality and surface characteristics of the final diamond. It determines the energy within the plasma environment, and adjusting it to the precise optimal level is essential for growing high-quality, single-crystal diamonds.

Power density is more than just a machine setting; it is the primary lever for controlling the plasma's energy and chemical activity. Mastering it is fundamental to managing the entire diamond growth process, from gas decomposition to the final crystal structure.

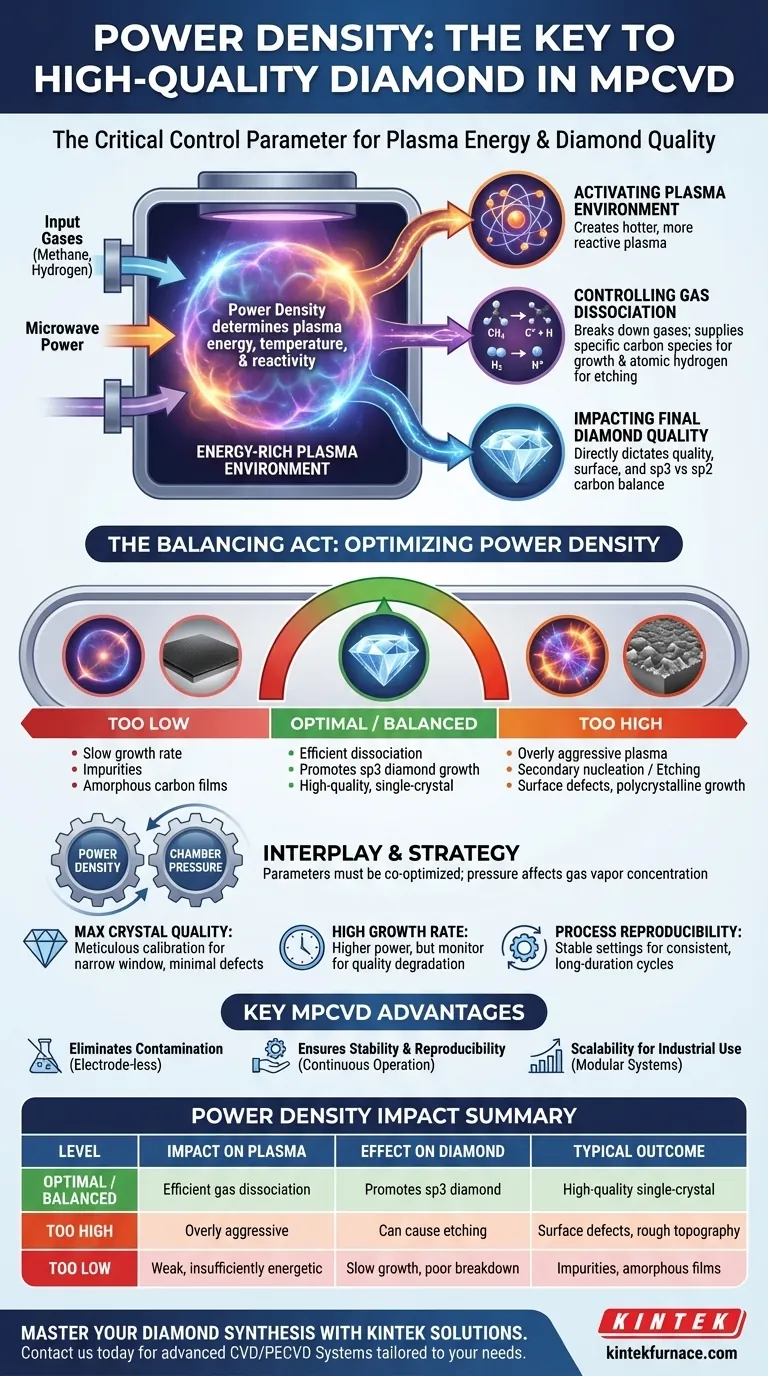

How Power density Governs Diamond Growth

Microwave Plasma Chemical Vapor Deposition (MPCVD) relies on creating an energy-rich plasma to break down source gases. Power density is the measure of microwave power applied to a specific volume, and it governs the intensity of this plasma.

Activating the Plasma Environment

The process begins by feeding gases, typically methane and hydrogen, into a vacuum chamber. The applied microwave power energizes these gases, stripping electrons and creating a glowing ball of plasma.

The power density directly correlates to the temperature and reactivity of this plasma. Higher density means a hotter, more energetic plasma, which profoundly impacts the subsequent chemical reactions.

Controlling Gas Dissociation and Growth

The energy in the plasma breaks down the source gas molecules. For example, methane (CH4) is decomposed into various carbon-containing radicals and hydrogen (H2) into atomic hydrogen (H).

Power density controls the efficiency of this dissociation. A well-tuned power density ensures a sufficient supply of the specific carbon species needed for diamond crystal formation while also producing enough atomic hydrogen to etch away any non-diamond carbon (like graphite).

Impacting Final Diamond Quality

As noted, different power densities result in varying diamond qualities. The goal is to find the "sweet spot" that promotes the growth of the desired sp3-bonded carbon (diamond) while suppressing sp2-bonded carbon (graphite).

An incorrect power density can lead to crystal defects, internal stress, or the formation of polycrystalline material instead of a single, flawless crystal.

Understanding the Trade-offs

Optimizing power density is a balancing act. Simply increasing power is not a guaranteed path to better or faster results, as it operates in tandem with other critical parameters like chamber pressure.

The Risk of Excessive Power

Too much power density can be detrimental. It can lead to an overly aggressive plasma that may cause secondary nucleation (the growth of unwanted new crystals on the surface) or even etch the growing diamond itself.

This can degrade the surface topography, making it rougher and reducing the overall quality of the single crystal.

The Problem with Insufficient Power

Conversely, if the power density is too low, the plasma will lack the energy to efficiently dissociate the source gases.

This results in very slow growth rates and can lead to the incorporation of impurities or the formation of poor-quality, amorphous carbon films, as the atomic hydrogen isn't active enough to clean the surface.

The Interplay with Chamber Pressure

Power density cannot be set in isolation. It is intrinsically linked to chamber pressure. Pressure affects the concentration and distribution of the gas vapor.

A power level that is optimal at a low pressure might be insufficient at a higher pressure. These two parameters must be co-optimized to create a stable and uniform plasma environment for even deposition.

Key Advantages of the MPCVD Method

Understanding parameters like power density is crucial because the MPCVD method itself offers significant advantages for high-quality diamond production.

Eliminating Contamination

Because it is an electrode-less process, MPCVD avoids a common source of contamination found in other methods. This enhances the purity of the resulting diamond.

Ensuring Stability and Reproducibility

The process is remarkably stable and can run continuously for extended periods. This allows for the growth of large, high-quality diamonds and ensures that results are reproducible, a key factor for industrial applications.

Scalability for Industrial Use

MPCVD systems are modular and scalable. This adaptability makes it possible to grow diamonds on larger substrates, paving the way for various advanced electronic and optical applications.

Making the Right Choice for Your Goal

Your approach to power density should be dictated by your specific objective. A precise calibration is necessary to move from theory to successful implementation.

- If your primary focus is maximum crystal quality: You must meticulously calibrate power density in conjunction with pressure to find the narrow optimal window that minimizes defects and promotes flawless single-crystal growth.

- If your primary focus is a high growth rate: A higher power density can accelerate deposition, but you must constantly monitor for the trade-off where quality begins to degrade due to etching or secondary nucleation.

- If your primary focus is process reproducibility: Your goal is to identify a stable power density setting that delivers consistent quality over long-duration growth cycles for reliable, industrial-scale production.

Ultimately, mastering power density is about balancing energy input to precisely control the atomic-scale environment where the diamond is formed.

Summary Table:

| Power Density Level | Impact on Plasma | Effect on Diamond Growth | Typical Outcome |

|---|---|---|---|

| Optimal / Balanced | Efficient gas dissociation, stable plasma | Promotes sp3 carbon (diamond) growth, suppresses graphite | High-quality, single-crystal diamond |

| Too High | Overly aggressive, hot plasma | Can cause etching or secondary nucleation | Surface defects, polycrystalline growth, rough topography |

| Too Low | Weak, insufficiently energetic plasma | Slow growth, poor gas breakdown | Impurities, amorphous carbon films, low quality |

Ready to Master Your Diamond Synthesis Process?

Understanding the critical role of parameters like power density is the first step. Achieving precise, repeatable control over your MPCVD process is the next.

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Tube Furnaces, Vacuum & Atmosphere Furnaces, and specialized CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements for growing high-quality diamonds.

Contact us today to discuss how our expertise and tailored solutions can help you optimize power density and achieve superior, reproducible results in your lab.

Visual Guide

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- How does a CVD tube furnace achieve high purity in gate media preparation? Master Precision Control for Flawless Films

- What are 2D heterostructures and how are they created using CVD tube furnaces? Unlock Atomic-Scale Material Engineering

- How can integrating CVD tube furnaces with other technologies benefit device fabrication? Unlock Advanced Hybrid Processes

- What customization options are available for CVD tube furnaces? Tailor Your System for Superior Material Synthesis

- What are the advantages of CVD tube furnace sintering systems? Achieve Superior Material Control and Purity